Alkaline and residual sludge coupled carbon cyclone releasing method and device

A technology for excess sludge and alkali residue, which is applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of increasing the removal load and achieve the goal of reducing sludge and improving biochemical efficiency of sewage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

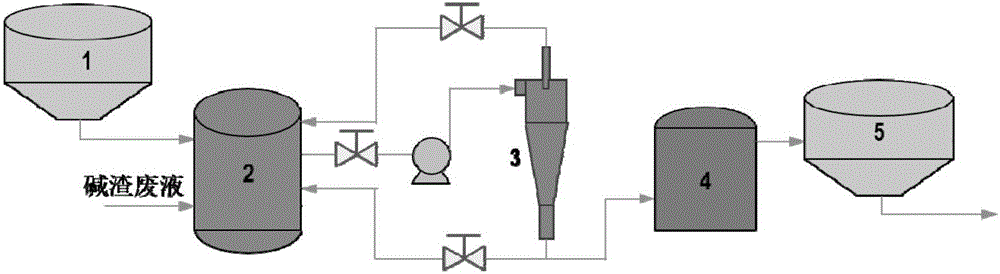

[0056] 1. Process flow

[0057] Such as figure 1 shown.

[0058] 2. Key equipment

[0059] The key equipment in this process is the cyclone carbon release device. The core tube of the cyclone carbon release device can be integrated and fixed with a steel frame according to the site structure. The equipment inlet, overflow port and underflow port are equipped with pressure gauges, flow meters and The valve is adjusted for operation. The processing capacity of the core tube of the cyclone carbon release device is adjustable, and the overall size of the single tube is Φ200×1500. The integrated complete device is equipped with inlet, underflow and overflow manifolds; all core tubes are connected in a detachable manner.

[0060] 3. Control

[0061] Under full load conditions, the processing capacity of the single-tube cyclone carbon release device is 12m 3 / h, the feed pressure is 0.15MPa (gauge pressure), the overflow split ratio is 5%, and the operating temperature is normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com