Control method of methyl alcohol splitting decomposition and hydrogen production hybrid power system based on engine waste heat recovery

A hybrid power system, methanol hydrogen production technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of low energy utilization rate, difficult hydrogenation, low engine thermal efficiency, etc., to improve energy utilization rate, solve The thermal efficiency is not high, and the combustion effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principle and system of the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be noted that this embodiment is illustrative rather than restrictive, and does not limit the scope of protection of the present invention.

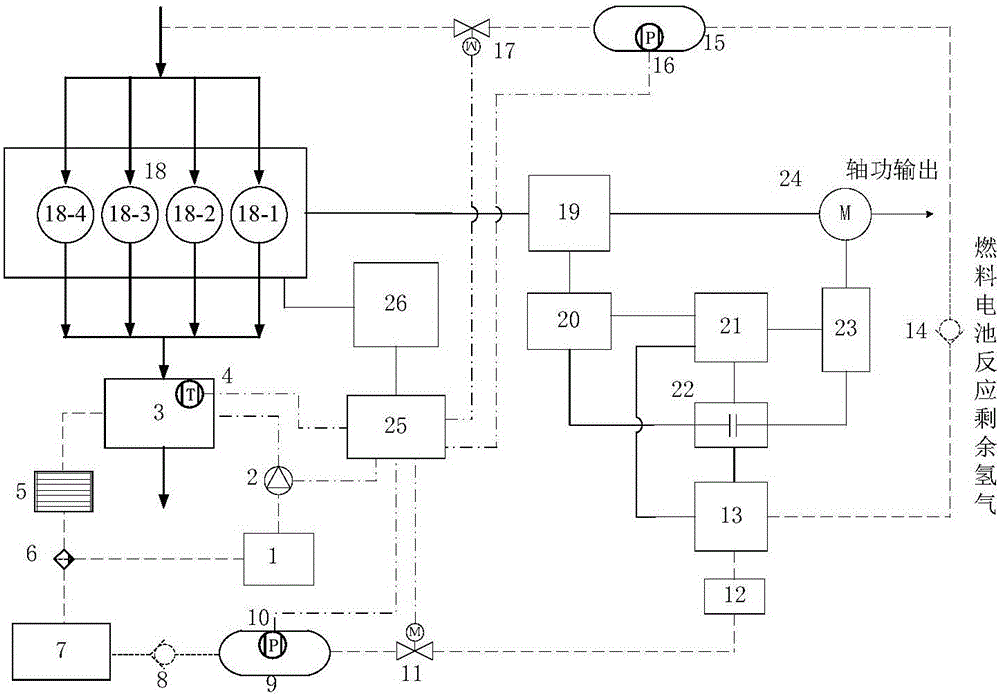

[0019] A preferred example according to the present invention is a hybrid power system of a vehicle, such as figure 1 shown. The hybrid power system is composed of methanol cracking hydrogen production device, fuel cell system and power output device, among which:

[0020] Liquid methanol fuel is pumped from the methanol fuel tank 1 into the methanol cracker 3 after being pressurized by the electric liquid pump 2, absorbing the high-temperature exhaust waste heat of the engine 18 and undergoing a cracking reaction to obtain a high-temperature and high-pressure mixed gas containing carbon monoxide and hydrogen. The gas enters the condenser 5 for condensation, and the unreacted high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com