Transient Electrical Test Method for Thermal Resistance of Liquid-Cooled Cold Plates

A cold and electrical technology, applied in the direction of single semiconductor device testing, measuring electricity, measuring devices, etc., to achieve the effect of simple multiple iterative testing, shortening the design optimization cycle, and short experiment preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Since the SOT-93 packaged transistor, such as a triode, can meet the test packaging requirements of T3Ster, it is possible to use a SOT-93 packaged transistor as the semiconductor device under test, and perform the following steps:

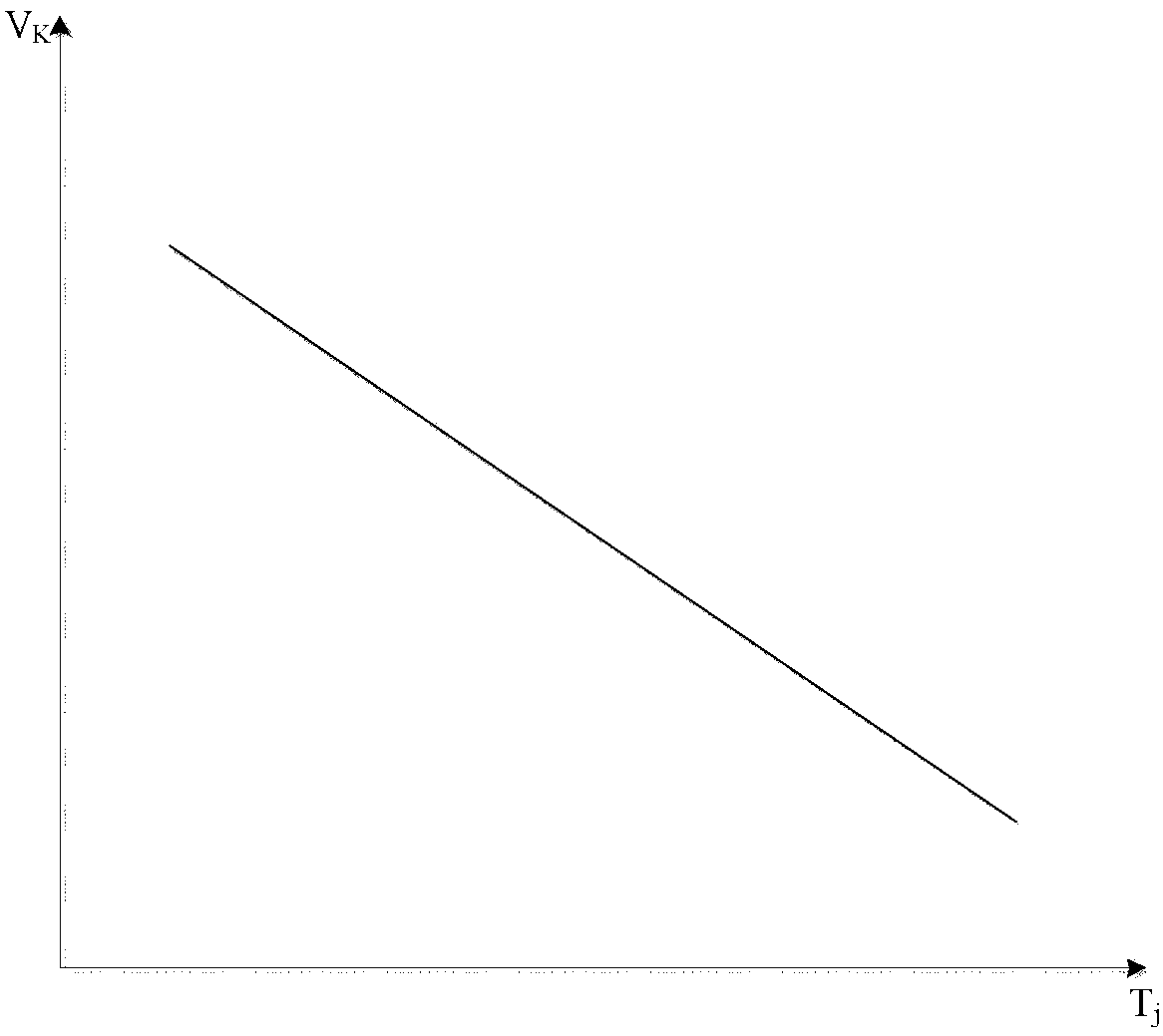

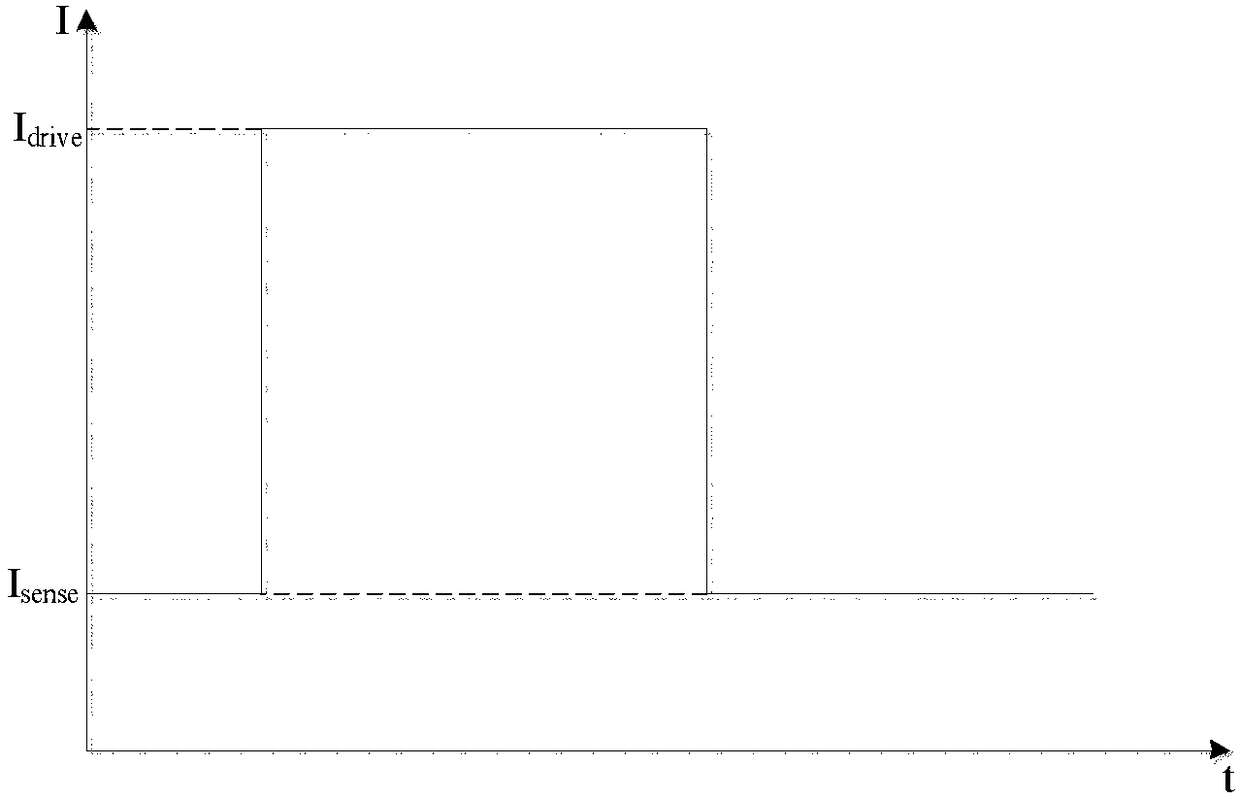

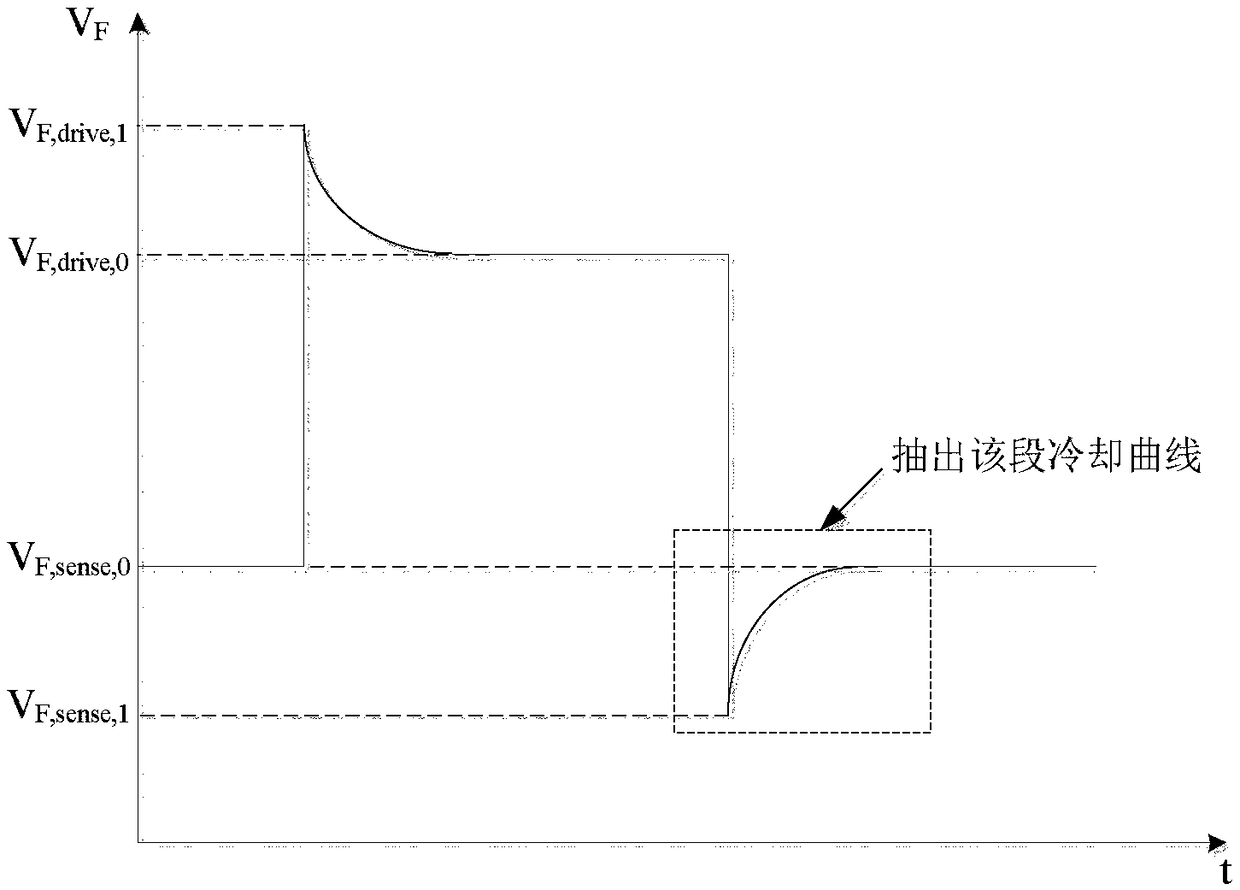

[0035] refer to figure 1 . First, measure the k coefficient of the triode: connect the triode and its adapter to the corresponding interface of the transient thermal tester T3Ster test host; In the T3Ster test software built into the computer, set the test temperature range according to the characteristics of the triode; perform the k coefficient test in the given temperature range and save the test results;

[0036] refer to Figure 8 . Second, according to Figure 8 As shown in the circuit connection diagram of the semiconductor device, connect the triode and its adapter to the corresponding interface of the T3Ster test host;

[0037] refer to Figure 9 . Third, according to the cold plate test semiconductor installation diagram, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com