Test method and test device for simulating natural inhomogeneous rusting of reinforcing steel bar in concrete

A test device and test method technology, applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as large thermal effect, non-uniform corrosion, inaccurate prediction results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1 The test method of the natural non-uniform corrosion of steel bar in the simulated concrete of the present invention may further comprise the steps:

[0085] 1) Preparation of the mold: Run the stainless steel wire through the side of the mold and lock it, and make the two ends of the stainless steel wire fall outside the mold. After adjusting the tension and length of the stainless steel wire, install the steel bar to be corroded on the mold Inside; the stainless steel wire is determined according to the purpose of the test whether its surface is provided with an insulating layer;

[0086] 2) Prepare the concrete specimen: pour concrete in the mold, remove the mold after 1 day of age, and then maintain the concrete specimen to the planned age; loosen the stainless steel wire before removing the mold;

[0087] 3) Constant current energization corrosion: according to the expected corrosion rate or rust layer thickness distribution, set the energization curre...

Embodiment 2

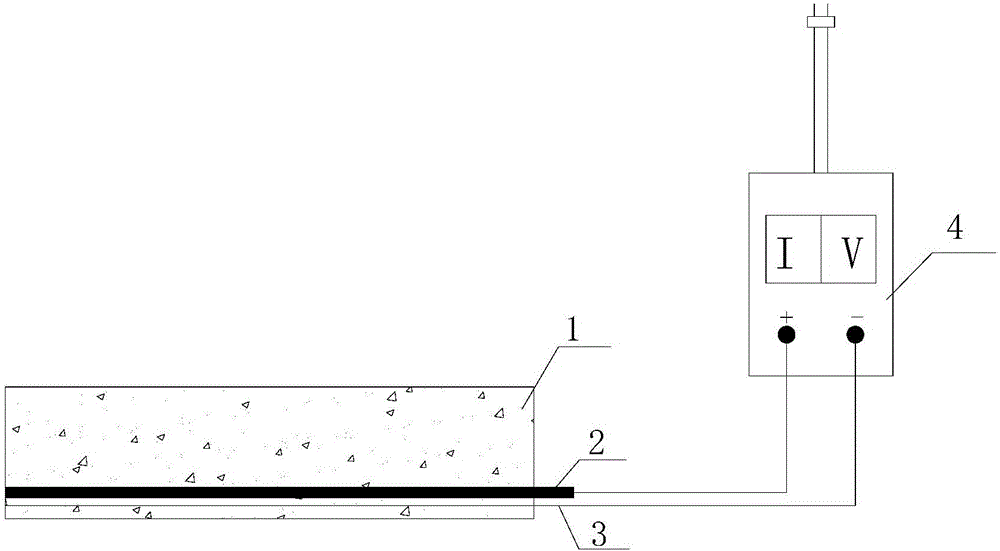

[0094] Embodiment 2 The test device constructed by the test method of simulating the natural non-uniform corrosion of steel bars in concrete as described in Example 1, including a mold unit, a force unit, a test piece and an electrification unit, and the described test piece is installed in the In the mold of the mold unit described above, steel bars 2 and stainless steel wires 3 are embedded inside the piece to be tested, and the described force unit is stuck on the stainless steel wire of the piece to be tested; The steel bar of the piece is electrically connected, and the negative pole of the energized unit is electrically connected with the cathode of the piece to be tested;

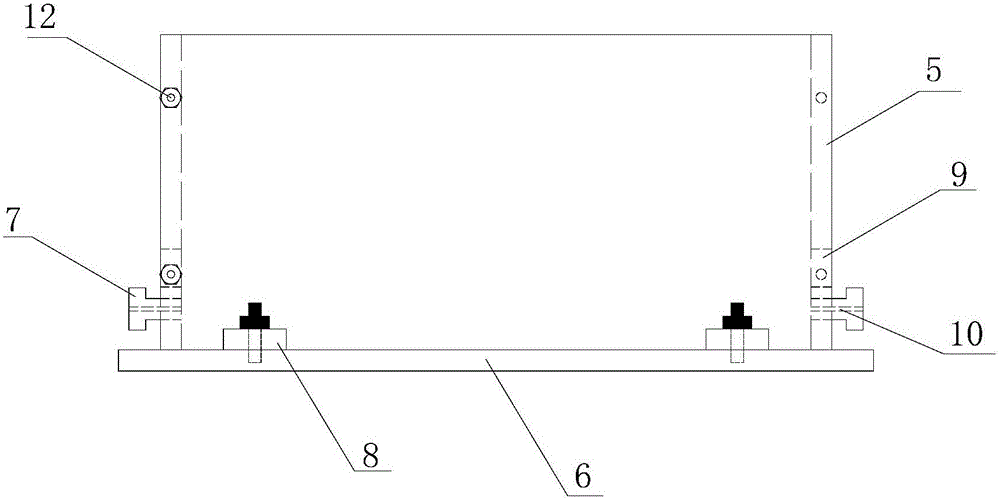

[0095] The mold unit includes a mold and a through-hole bolt 7 for pouring the piece to be tested, and the symmetrical two sides of the mold are reserved for the first hole 9 for penetrating the steel bar 2 and the second hole 10 for penetrating the stainless steel wire 3; The through-hole bolt 7 is ...

Embodiment 3

[0103] Embodiment 3 Taking the measurement of the water-cement ratio of 0.53 and the mix ratio of cement: water: sand: coarse aggregate = 1: 0.53: 2.0: 3.0 as an example, the concrete will be energized and corroded after the built-in stainless steel wire, and the work of the present invention will be described in detail .

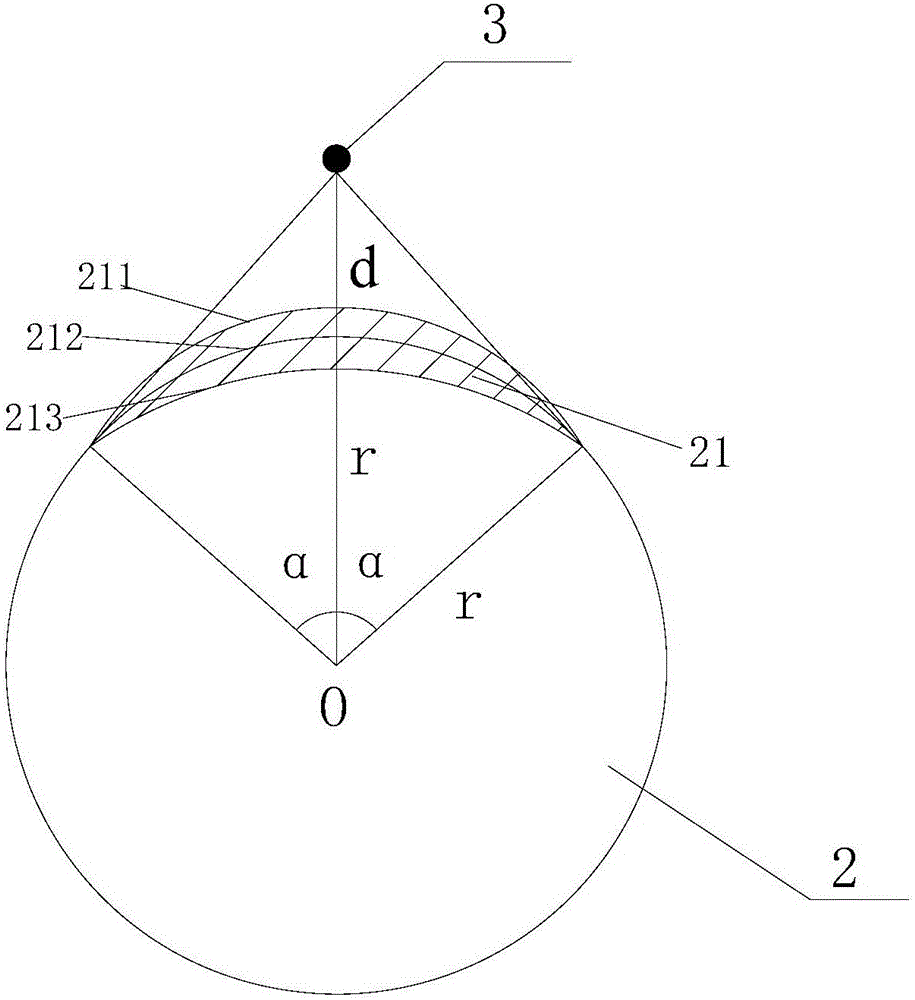

[0104] The raw material of this embodiment mixing concrete is: cement is P.I52.5 grade Portland cement, and sand adopts the river sand of fineness modulus 2.5~2.6, and coarse aggregate adopts the crushed stone of continuous gradation (maximum grain size 20mm), the water is tap water. The size of the specimen is 100×100×400, and the steel bars and stainless steel wires to be corroded are pre-embedded in the specimen. The steel bar model adopts HPB300, and the thickness of the protective layer is 20mm. The diameters of steel bars and stainless steel wires are 12mm and 1mm respectively, and the net distance between them is 6mm. At this time, the central ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com