Direct sound production test device of large-proportion propeller model

A thruster, large-scale technology, used in the testing of machine/structural components, measuring devices, fluid dynamics tests, etc., can solve problems such as the impossibility of the thruster proportion being too large, the effective noise measurement frequency is high, and the low-frequency measurement is difficult. , to achieve the effect of short test cycle, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

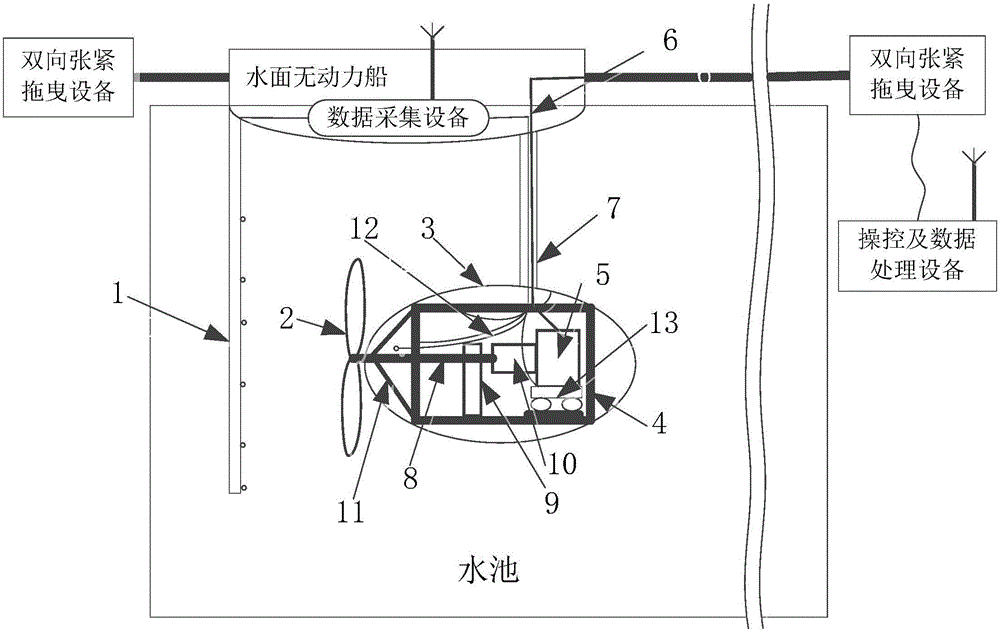

[0025] Such as figure 1 As shown, a direct sound test device of a large-scale propeller model, the test device includes two-way tensioned towing equipment, a non-powered ship on the water surface, data acquisition equipment, power cables 6, control and data processing equipment, hydrophones Array 1, propeller model 2, main shaft system, non-watertight casing 3, watertight casing 4, sensor 12, support 11, rigid connector 7, motor 5 and motor vibration damping mechanism 13;

[0026] The hydrophone array 1 is a semi-cylindrical surface formed by hydrophones evenly distributed in the direction of the vertical horizontal plane, and the projection on the horizontal plane is a semicircle; the size of the propeller model 2 is the same as that of the actual marine propeller The ratio is 1:10;

[0027] The non-watertight casing 3 is made of a composite material with a high damping coefficient; the watertight casing 4 is made of steel with a thickness of 15mm, and damping materials are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com