Glycol diester strong viscous storage battery sealant based on epoxy resin and preparation method thereof

A technology of ethylene glycol diester methacrylate and epoxy resin, applied in adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problem of damage to the battery shell and high bonding strength problem, achieve the effect of increasing curing speed and bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of ethylene glycol diester strong viscous battery sealant based on epoxy resin, it is characterized in that: comprise A component and B component; Described A component is made of dibutyltin dilaurate, PC-polycarbonate, tertiary Butyl hydroperoxide, composed of neoprene; B component composed of epoxy resin, ethylene glycol diester methacrylate, acrylate rubber, N'-dimethylurea, propylene carbonate, defoamer, paraffin ; Wherein the A component includes: 15-25 parts of dibutyltin dilaurate, 15-25 parts of PC-polycarbonate, 2-6 parts of tert-butyl hydroperoxide, 10-25 parts of Neoprene composition; the B component includes: 60-80 parts of epoxy resin, 10-20 parts of ethylene glycol diester methacrylate, 5-15 parts of acrylate rubber, 3-15 parts of N'-dimethylurea, 10-25 parts of propylene carbonate, 10-15 parts of defoamer, 0.1-5 parts of paraffin.

[0018] The A component includes: 20 parts of dibutyltin dilaurate, 20 parts of PC-polycarbonate, 4 parts of tert-but...

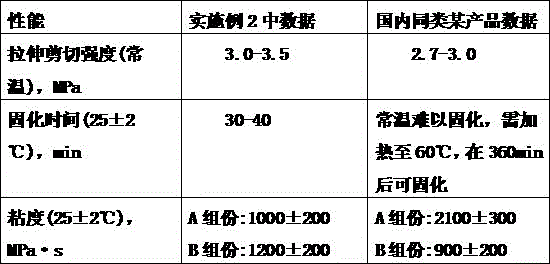

Embodiment 2

[0026] A kind of ethylene glycol diester strong viscous battery sealant based on epoxy resin, it is characterized in that: comprise A component and B component; Described A component is made of dibutyltin dilaurate, PC-polycarbonate, tertiary Butyl hydroperoxide, composed of neoprene; B component composed of epoxy resin, ethylene glycol diester methacrylate, acrylate rubber, N'-dimethylurea, propylene carbonate, defoamer, paraffin ; Wherein the A component includes: 15-25 parts of dibutyltin dilaurate, 15-25 parts of PC-polycarbonate, 2-6 parts of tert-butyl hydroperoxide, 10-25 parts of Neoprene composition; the B component includes: 60-80 parts of epoxy resin, 10-20 parts of ethylene glycol diester methacrylate, 5-15 parts of acrylate rubber, 3-15 parts of N'-dimethylurea, 10-25 parts of propylene carbonate, 10-15 parts of defoamer, 0.1-5 parts of paraffin.

[0027] The A component is mixed at a temperature of 36-66°C and an air pressure of 10pa, and the component B is mixe...

Embodiment 3

[0032] The preferred version of the present invention is: the A component includes: 20 parts of dibutyltin dilaurate, 20 parts of PC-polycarbonate, 4 parts of tert-butyl hydroperoxide, 15 parts of neoprene Composition; the B component includes: 70 parts of epoxy resin, 15 parts of ethylene glycol diester methacrylate, 10 parts of acrylate rubber, 8 parts of N'-dimethylurea, 15 parts of Propylene carbonate, 12 parts of defoamer, 3 parts of paraffin.

[0033] Component A is at a temperature of 40°C, and component B is at a temperature of 45°C and an air pressure of 10pa. Mix the raw materials in component A and component B according to the ratio, and then stand still for packaging. When using, directly mix component A , After component B is mixed evenly according to the weight ratio, the potting operation can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com