Method for rapid preparation of c/sic ceramic composites with matrix pre-introduction

A ceramic composite material, fast technology, applied in the field of composite ceramic materials, can solve the problems of shortening the production cycle, long preparation cycle, and reducing raw materials, etc., to achieve the effects of shortening the production cycle, reducing material costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for pre-introducing a matrix to prepare a C / SiC material 1, comprising the following steps:

[0035] 1) Braided body processing: the fabric adopts carbon cloth plus mesh tire puncture structure, carbon cloth and mesh tire are woven alternately, and 20g of SiC powder is evenly spread on each layer of mesh tire; the specific process parameters are as follows:

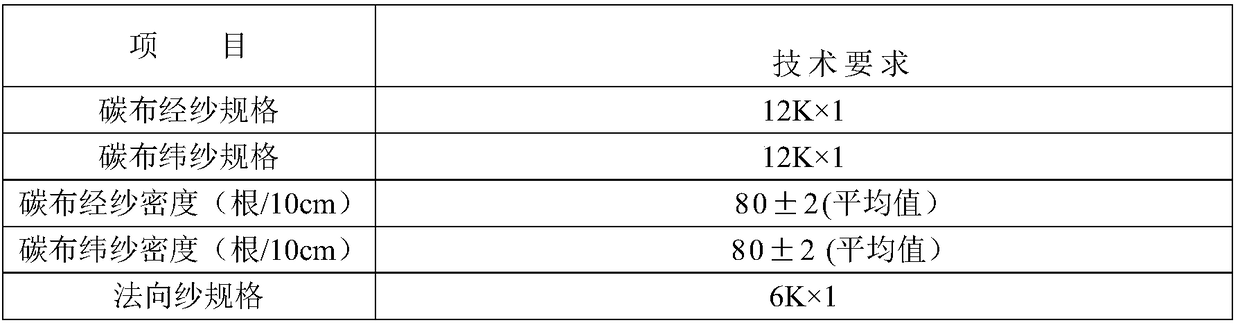

[0036] Table 1 Embodiment 1 fabric structure parameter list

[0037] project

skills requirement

Carbon cloth warp specifications

12K×1

Carbon cloth weft specification

12K×1

Carbon cloth warp density (root / 10cm)

80±2(mean value)

Carbon cloth weft yarn density (root / 10cm)

80±2(mean value)

Normal yarn specification

6K×1

Normal weft density (needle / 1cm)

2 stitches / 1cm

Normal warp density (pin / 1cm)

2 stitches / 1cm

Meridian volume content

16~18%

Weft volume content

16~18%

normal volume content

2~5%...

Embodiment 2

[0046] A method for pre-introducing a matrix to prepare a C / SiC material 2, comprising the following steps:

[0047] 1) Braided body processing: The fabric adopts a carbon cloth plus mesh tire puncture structure, carbon cloth and mesh tires are woven alternately, and 30g of SiC powder is evenly spread on each layer of mesh tires. The specific process parameters are as follows:

[0048] Table 2 Example 2 fabric structure parameter table

[0049] project

skills requirement

Carbon cloth warp specifications

12K×1

Carbon cloth weft specification

12K×1

Carbon cloth warp density (root / 10cm)

80±2(mean value)

Carbon cloth weft yarn density (root / 10cm)

80±2(mean value)

Normal yarn specification

6K×1

Normal weft density (needle / 1cm)

2 stitches / 1cm

Normal warp density (pin / 1cm)

2 stitches / 1cm

Meridian volume content

16~18%

Weft volume content

16~18%

normal volume content

2...

Embodiment 3

[0058] A method for pre-introducing a matrix into a C / SiC material, comprising the following steps:

[0059] 1) Braided body processing: the fabric adopts a carbon cloth plus mesh tire puncture structure, carbon cloth and mesh tires are woven alternately, and 10g of SiC powder is evenly spread on each layer of mesh tires. The specific process parameters are as follows:

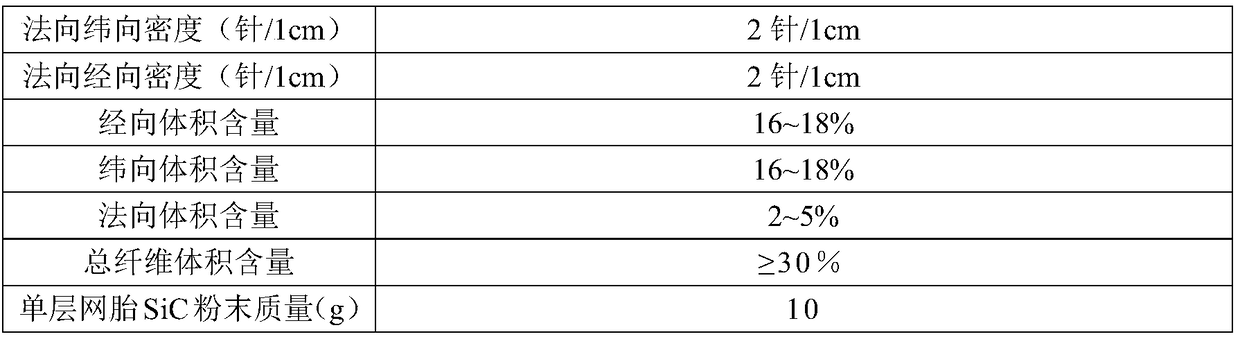

[0060] Table 3 Example 3 fabric structure parameter table

[0061]

[0062]

[0063] 2) Pretreatment of braided body Soak the braided body in step 1) in acetone solution for 2 hours, handle with care during the soaking process, and do not shake the container solution. Put the braided body into an oven at 120°C, keep warm for 6 hours and dry;

[0064] 3) Perform CVD pretreatment on the braided body in step 2): propylene is used as the carbon source gas, the flow rate is 40mL / min, nitrogen or argon is used as the dilution gas; the deposition reaction temperature is 900°C, the deposition pressure is 8KPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com