Efficient air purification type photocatalyst filter screen and preparation method thereof

A high-efficiency air and filter technology, applied in the field of air purification, can solve the problems of reducing the utilization rate of photocatalyst materials, small effective contact area, and reducing catalytic degradation efficiency, so as to improve utilization rate and catalytic efficiency, broad market application prospects, photocatalyst Good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

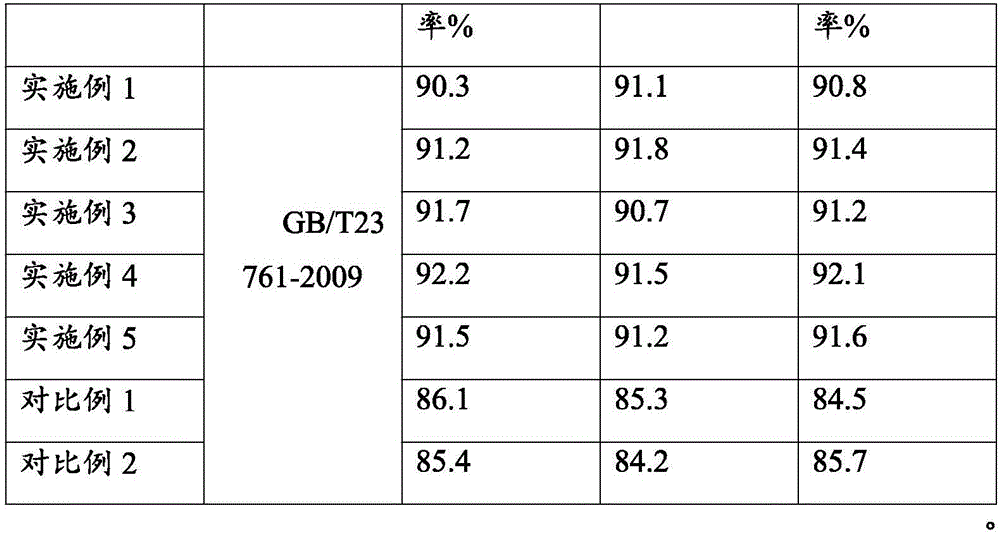

Embodiment 1

[0030] The high-efficiency air purification photocatalyst filter screen includes a filter screen base material, and a photocatalyst is arranged on the filter screen base material, and the photocatalyst is composed of the following components in parts by weight: 7 parts of titanium dioxide, 0.3 parts of molybdenum oxide, cerium 0.2 parts of oxides, 0.1 parts of lanthanum oxides, 0.2 parts of nickel oxides, 0.05 parts of platinum oxides, 3 parts of silicon dioxide, 5 parts of nano-tin dioxide, 5 parts of silica gel powder, 3 parts of alumina, 8 parts of meerschaum part, 0.5 part of iron acetylacetonate, 1 part of terpyridyl ruthenium chloride;

[0031] The average particle diameters of the silica, silica gel powder, alumina and sepiolite are all less than 100 mesh.

[0032] The material of the filter screen base material is drawn metal, drawn alloy, natural fiber or synthetic fiber. Preferably, the material of the filter screen substrate is aluminum, nickel, alumina fiber or fo...

Embodiment 2

[0044] The high-efficiency air purification photocatalyst filter screen includes a filter screen base material, and a photocatalyst is arranged on the filter screen base material, and the photocatalyst is composed of the following components in parts by weight: 13 parts of titanium dioxide, 1.1 parts of molybdenum oxide, cerium 0.9 parts of oxide, 1.4 parts of lanthanum oxide, 0.6 parts of nickel oxide, 0.11 parts of platinum oxide, 8 parts of silicon dioxide, 9 parts of nano-tin dioxide, 11 parts of silica gel powder, 6 parts of alumina, 12 parts of sepiolite 1.8 parts, 1.8 parts of iron acetylacetonate, 1.5 parts of terpyridyl ruthenium chloride;

[0045] The average particle diameters of the silica, silica gel powder, alumina and sepiolite are all less than 100 mesh.

[0046] The material of the filter screen base material is drawn metal, drawn alloy, natural fiber or synthetic fiber. Preferably, the material of the filter screen substrate is aluminum, nickel, alumina fibe...

Embodiment 3

[0058] The high-efficiency air purification photocatalyst filter screen includes a filter screen base material, and a photocatalyst is arranged on the filter screen base material, and the photocatalyst is composed of the following components in parts by weight: 20 parts of titanium dioxide, 2 parts of molybdenum oxide, cerium 1.6 parts of oxide, 1.8 parts of lanthanum oxide, 1.1 parts of nickel oxide, 0.18 parts of platinum oxide, 14 parts of silicon dioxide, 12 parts of nano-tin dioxide, 18 parts of silica gel powder, 9 parts of alumina, 18 parts of sepiolite 3 parts, 3 parts of iron acetylacetonate, 2 parts of terpyridyl ruthenium chloride;

[0059] The average particle diameters of the silica, silica gel powder, alumina and sepiolite are all less than 100 mesh.

[0060] The material of the filter screen base material is drawn metal, drawn alloy, natural fiber or synthetic fiber. Preferably, the material of the filter screen substrate is aluminum, nickel, alumina fiber or f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com