A cu-doped cubic ca2si thermoelectric material

A technology of thermoelectric materials and cubic phase, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, metal silicide, etc., can solve the problems of thermoelectric materials that have not been reported, and meet the needs of large-scale production, The effect of controllable composition and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

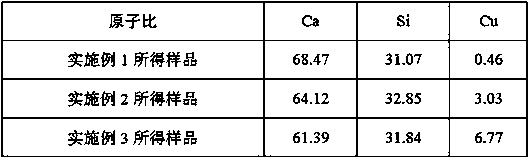

[0024] A Cu-doped cubic Ca phase 2 The preparation method of Si thermoelectric material comprises the following steps:

[0025] 1) Mix Ca powder, Si powder and Cu powder uniformly under an Ar gas protective atmosphere at a molar ratio of Ca, Si and Cu of 81:20:0.5 to obtain a mixture powder;

[0026] 2) Put the mixture powder obtained in step 1), grinding steel balls, vacuum stainless steel ball milling tank and electronic balance into a glove box filled with Ar gas at an atmospheric pressure; accurately weigh the grinding steel balls in the glove box at a weight ratio of 3:1 and the mixture powder, and put it into a vacuum stainless steel ball mill jar, then seal the vacuum stainless steel ball mill jar to avoid oxygen entry; then take out the vacuum stainless steel ball mill jar from the glove box;

[0027] 3) Put the vacuum stainless steel ball mill tank prepared in step 2) into the ball mill, and ball mill at a speed of 2000 rpm for 5 hours to fully react the mixture powd...

Embodiment 2

[0030] A Cu-doped cubic Ca phase 2 The preparation method of Si thermoelectric material comprises the following steps:

[0031] 1) Mix Ca powder, Si powder and Cu powder uniformly under the protective atmosphere of Ar gas according to the molar ratio of Ca, Si and Cu of 81:20:6 to obtain the mixture powder;

[0032] 2) Put the mixture powder obtained in step 1), grinding steel balls, vacuum stainless steel ball milling tank and electronic balance into a glove box filled with Ar gas at an atmospheric pressure; accurately weigh the grinding steel balls in the glove box according to a weight ratio of 16:1 and the mixture powder, and put it into a vacuum stainless steel ball mill jar, then seal the vacuum stainless steel ball mill jar to avoid oxygen entry; then take out the vacuum stainless steel ball mill jar from the glove box;

[0033] 3) Put the vacuum stainless steel ball mill tank prepared in step 2) into the ball mill, and ball mill at a speed of 500 rpm for 100 hours to ...

Embodiment 3

[0038] A Cu-doped cubic Ca phase 2The preparation method of Si thermoelectric material comprises the following steps:

[0039] 1) Mix Ca powder, Si powder and Cu powder uniformly in an Ar gas protective atmosphere at a molar ratio of Ca, Si and Cu of 81:20:10 to obtain a mixture powder;

[0040] 2) Put the mixture powder obtained in step 1), grinding steel balls, vacuum stainless steel ball milling tank and electronic balance into a glove box filled with Ar gas at an atmospheric pressure; accurately weigh the grinding steel balls in the glove box at a weight ratio of 8:1 and the mixture powder, and put it into a vacuum stainless steel ball mill jar, then seal the vacuum stainless steel ball mill jar to avoid oxygen entry; then take out the vacuum stainless steel ball mill jar from the glove box;

[0041] 3) Put the vacuum stainless steel ball mill tank prepared in step 2) into the ball mill, and mill at a speed of 1000 rpm for 50 hours to fully react the mixture powder;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com