High-temperature-resistance wide-temperature-region self-lubricating composite material and preparation method thereof

A composite material and wide temperature range technology, which is used in the field of high temperature resistant and wide temperature range self-lubricating composite materials and their preparation, can solve the problem that the narrow applicable temperature range cannot meet the actual use requirements of the wide temperature range, there is no public report, and the lubrication effect is lost. problem, to achieve the effect of high density, good structure and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] According to mass percentage: 12%Ag, 5%BaF 2 / CaF 2 Eutectic, 4% graphite powder, 79% nickel-based alloy powder, each powder material was weighed separately. Among them, the composition of nickel-based alloy powder is 74%Ni, 15%Cr, 4%Mo, 5%Ti, 2%Al. Put various powders into WC ball milling tanks, the grinding balls are WC, and the ball-to-material ratio is 5:1, and then put the ball milling tanks in a high-energy ball mill, and mix them for 5 hours at a speed of 200 rpm to obtain mixed powders. Put the mixed powder into a graphite mold, and then place it in a vacuum hot-press sintering furnace for sintering. The parameters are: vacuum degree 1×10 -1 Pa, the heating rate is 25°C / min, the sintering temperature is 1250°C, the pressure is 35 MPa, and the holding time is 25min. After sintering, the material is cooled to room temperature with the furnace to obtain a self-lubricating composite material with high temperature resistance and wide temperature range.

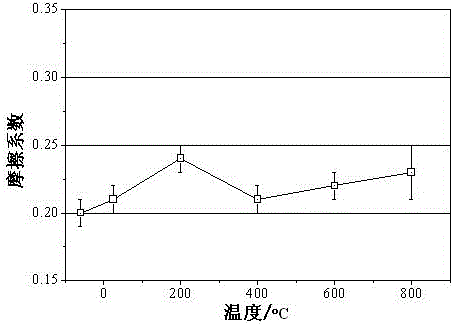

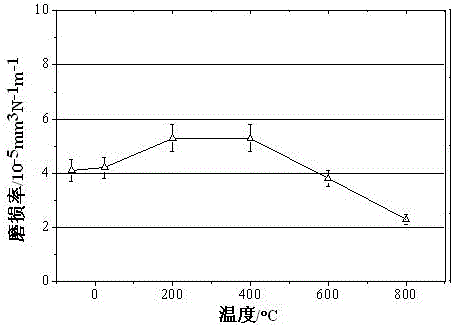

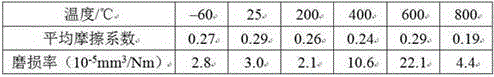

[0020] T...

Embodiment 2

[0024] According to mass percentage: 15%Ag, 8%BaF 2 / CaF 2 Eutectic, 2% graphite powder, 75% nickel-based alloy powder, weigh each powder material respectively. Among them, the composition of nickel-based alloy powder is 70%Ni, 18%Cr, 3%Mo, 6%Ti, 3%Al. Put various powders into WC ball milling tanks, the grinding balls are WC, and the ball-to-material ratio is 4:1, then put the ball milling tanks in a high-energy ball mill, and mix for 8 hours at a speed of 180 rpm to obtain mixed powders. Put the mixed powder into a graphite mold, and then place it in a vacuum hot-press sintering furnace for sintering. The parameters are: vacuum degree 2×10 -1 Pa, the heating rate is 30°C / min, the sintering temperature is 1200°C, the pressure is 30 MPa, and the holding time is 20min. After sintering, the material is cooled to room temperature with the furnace to obtain a self-lubricating composite material with high temperature resistance and wide temperature range.

[0025] The room tempe...

Embodiment 3

[0029]According to mass percentage: 20%Ag, 10%BaF 2 / CaF 2 Eutectic, 1% graphite powder, 69% nickel-based alloy powder, each powder material was weighed separately. Among them, the composition of nickel-based alloy powder is 66%Ni, 20%Cr, 2%Mo, 8%Ti, 4%Al. Put various powders into WC ball milling tanks, the grinding balls are WC, and the ball-to-material ratio is 3:1, then put the ball milling tanks in a high-energy ball mill, and mix for 10 hours at a speed of 150 rpm to obtain mixed powders. Put the mixed powder into a graphite mold, and then sinter in a vacuum hot-press sintering furnace, the parameters are: vacuum degree 4×10 -1 Pa, the heating rate is 35°C / min, the sintering temperature is 1150°C, the pressure is 40 MPa, and the holding time is 15 minutes. After the sintering, the material is cooled to room temperature with the furnace to obtain a self-lubricating composite material with high temperature resistance and wide temperature range.

[0030] The room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com