Micro-nano coating material with low surface energy and preparation method thereof

A coating material, low surface energy technology, used in coatings, powder coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficult to obtain a variety of functional coating materials, complex designs, etc., to achieve high hardness, adhesion Strong and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

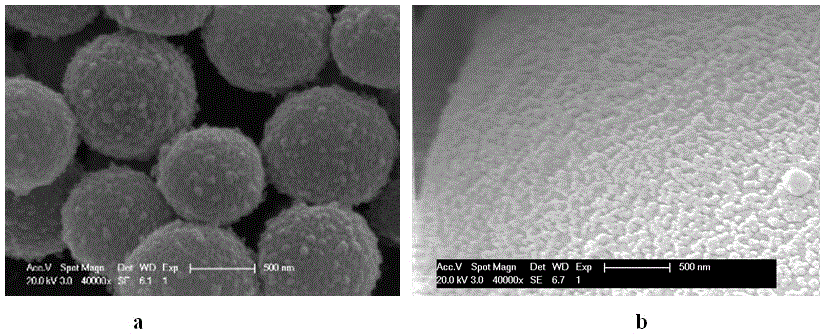

[0054] Monodisperse positively charged polymethyl methacrylate (PMMA) microspheres with a particle size of 20 microns were prepared by dispersion polymerization, the aqueous dispersion was diluted to a solid content of 10%, and then 5% of the particle size was added to 50 nm Siloxane modified silica sol (SiO 2 ), stirred at 80°C for 20 hours, separated, washed, and dried in an oven at 70°C for 100 hours. Strawberry-type hydrophobic PMMA / SiO can be obtained 2 Micro-nano structure composite microspheres.

[0055] Put 5 grams of strawberry type PMMA / SiO 2 Micro-nano structure composite microspheres, 10 grams of methyl methacrylate (MMA), 5 grams of n-butyl acrylate (BA), 2 grams of acrylic acid (AA), 4 grams of vinyl siloxane monomer, 0.5 grams of azobis Isobutyronitrile (AIBN) and 74 grams of butyl acetate were mixed, and the mixture was reacted in a 500mL four-neck bottle at 70-80°C for 24 hours to prepare a low surface energy micro-nano coating material, which was coated on...

Embodiment 2

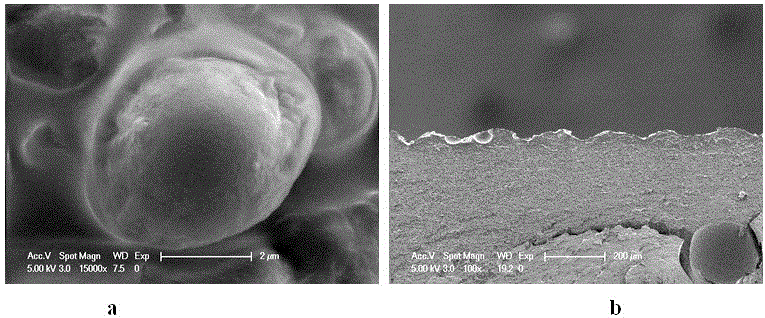

[0057] Weigh 40 g of polydimethylsiloxane microspheres (PDMS) with a particle size of 50 microns and hydroxyl groups on the surface, 60 grams of water, and 1 g of polydimethylsiloxane with a particle size of 10 nm and alkoxy groups on the surface Oxane microspheres (PDMS), stirred at 50°C for 100 hours, separated, washed, and dried in a vacuum oven at 50°C for 24 hours. The hydrophobic PDMS / PDMS micro-nano structure composite microspheres can be obtained.

[0058] 50 grams of PDMS / PDMS micro-nano structure composite microspheres, 10 grams of silicone modified fluororesin, 4 grams of titanium dioxide, 3 grams of kaolin, 3 grams of barium sulfate, 20 grams of propylene glycol butyl ether acetate, 10 grams of acetone, 0.1 grams Defoamer, 0.2 g dispersant, 0.7 g simethicone, stirred at room temperature for 2 hours to prepare a low surface energy micro-nano coating material, and the low surface energy coating material with groove structure can be obtained by roller coating. Capabl...

Embodiment 3

[0060] Weigh glass microspheres with a particle size of 200 microns, use the hydrofluoric acid etching method to make the surface of the glass microspheres have carboxyl groups, mix 70g of modified glass microspheres, 10 grams of nano-titanium dioxide (TiO 2 ), 20 grams of water, stirred at room temperature for 50 hours, separated and washed, and the product was placed at room temperature for 2 days to obtain hydrophobic TiO 2 / Glass micro-nano structure composite microspheres.

[0061] 70 g TiO 2 / glass micro-nano structure composite microspheres, 20 grams of ultraviolet curing (UV) acrylate-polyurethane resin, 10 grams of ultraviolet curing (UV) polyester-polyurethane resin, stirred at 40 ° C for 20 minutes to prepare low surface energy microspheres The nano-coating material adopts ultraviolet curing (UV) and etching methods to obtain a low surface energy micro-nano coating with a groove structure. The water contact angle of the coating is 120°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com