Light-cured resin material for 3D printing

A light-curing resin and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of high water absorption and damage to the stability of light-cured workpieces, and achieve the effects of low water absorption, expanded use, and reduced water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

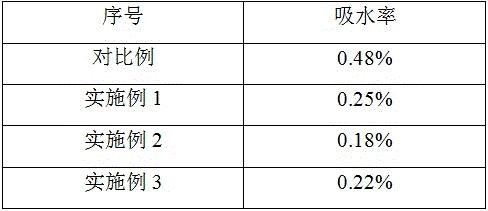

Embodiment 1

[0021] A photocurable resin material, wherein the mass percentages of each component are: bisphenol A type E-51 epoxy resin 51%, tricyclodecane dimethanol diacrylate 2%, trimethylol propane triacrylate 5% %, Dipropylene Glycol Diacrylate 5%, Polyacrylate Elastomer Particles 5%, 3-Hydroxymethyl-1-Oxetane 7%, 2-Hydroxymethyl Oxetane 11%, Initiator 6%, trifluoroethyl acrylate 8%.

Embodiment 2

[0023] A light-curing resin material, wherein the mass percentages of each component are: bisphenol A type E-51 epoxy resin 20%, alicyclic epoxy resin 30%, hydrogenated bisphenol A type epoxy resin 10%, 2 -Methyl-1,3-propanediol diacrylate 12%, trimethylolpropane trimethacrylate 8%, polyurethane elastomer particles 2%, 3-hydroxymethyl-1-oxetane 5% , initiator 8%, trifluoroethyl methacrylate 3%, pentafluoropropyl acrylate 2%.

Embodiment 3

[0025] A light-curing resin material, wherein the mass percentages of each component are: bisphenol A type E-51 epoxy resin 6%, alicyclic epoxy resin 20%, hydrogenated bisphenol A type epoxy resin 20%, two Propylene glycol diacrylate 7%, 1,6-hexanediol diacrylate 3%, silica particle modified epoxy resin 7%, polyacrylate elastomer particle 10%, 2-hydroxymethyloxetane Alkane 8%, 3-methyl-3-hydroxymethyl oxetane 15%, initiator 10%, pentafluoropropyl methacrylate 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com