Flame-retardation sulfur-containing macromolecular triazine charring agent and preparation method thereof

A technology of triazine and char-forming agent, applied in the direction of organic chemistry, etc., can solve the problems of unsatisfactory char-forming effect, limiting the application scope of IFR, limiting the application field of PP, etc., and achieves good char-forming effect and good char-forming efficiency. , the effect of good environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 The structural formula of the carbon forming agent described in Embodiment 1 is:

[0037]

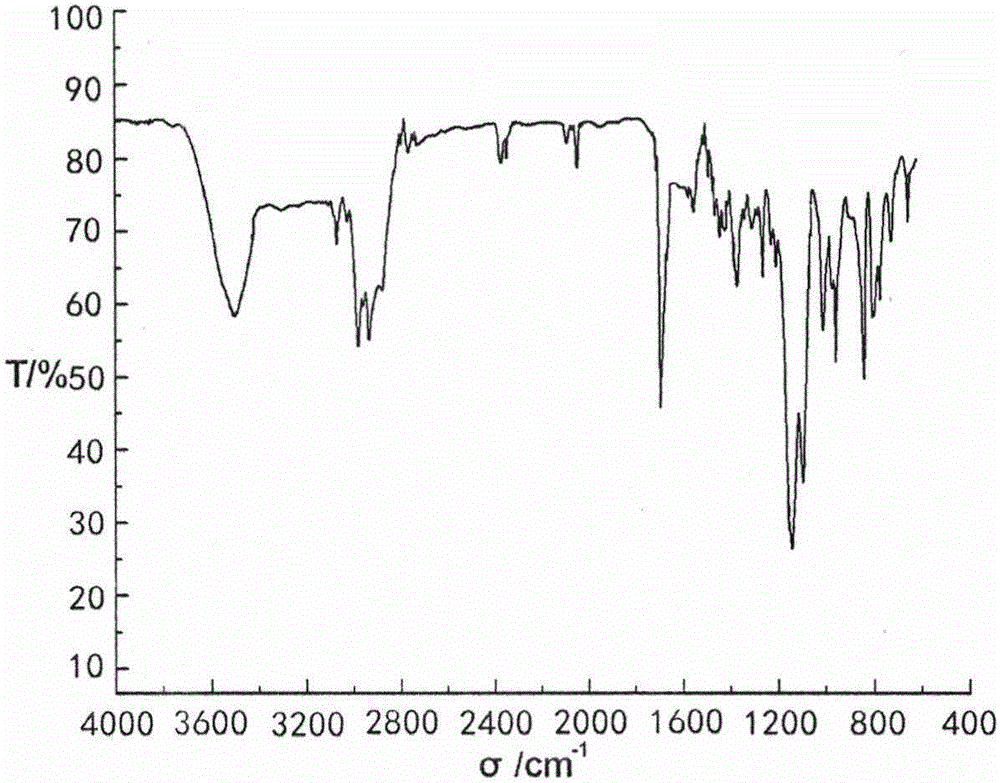

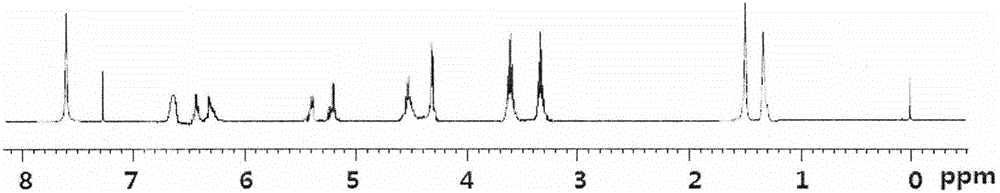

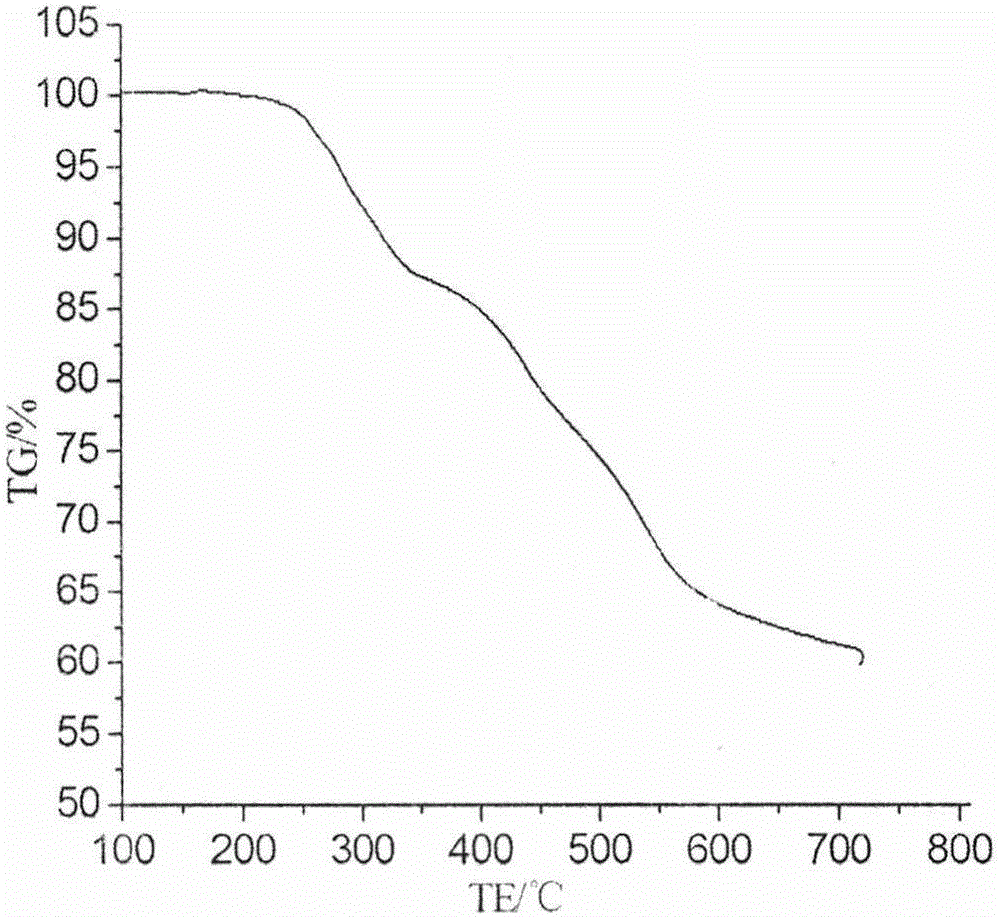

[0038] The preparation method is: add 200ml of acetonitrile and 29.72g (0.1mol) triglycidyl isocyanurate to a 500ml four-neck flask equipped with a stirrer, a thermometer, a constant temperature dropping funnel and a high-efficiency reflux condenser, start stirring, and drop Add 6.11g (0.1mol) of ethanolamine, after dripping, raise the temperature to 30°C, and keep it warm for 1.5h to make the pH of the reaction solution reach 7-8; then add 7.60g (0.1mol) of thiourea, and control the temperature during the addition Do not exceed 50°C, and then reflux for 6 hours to make the pH of the solution reach 7-8. After cooling, filter with suction (solvent recovery), wash with water, dry and pulverize to obtain the product CFA-1; the yield is 98.3% , 1% thermal weight loss decomposition temperature is 265.0 ° C, through FTIR and NMR test analysis, to determine the structure...

Embodiment 2

[0039] Embodiment 2 The structural formula of the carbon forming agent described in Embodiment 2 is:

[0040]

[0041] The preparation method is: add 250ml of acetonitrile and 29.72g (0.1mol) triglycidyl isocyanurate to a 500ml four-neck flask equipped with a stirrer, a thermometer, a constant temperature dropping funnel and a high-efficiency reflux condenser, start stirring, and drop Add 6.11g (0.1mol) ethanolamine, after dripping, raise the temperature to 30°C, and keep it warm for 1.5h to make the pH value of the reaction solution reach 7-8; then add 9.11g (0.1mol) thiosemicarbazide, and control The temperature does not exceed 50°C, and then reflux for 7 hours to make the pH of the solution reach 7-8. After cooling, suction filtration (solvent recovery), washing, drying and crushing, the product CFA-2 is obtained; the yield is 97.5 %, 1% thermal weight loss decomposition temperature is 268.3 ° C, through FTIR and NMR test analysis, to determine the structure of the produ...

Embodiment 3

[0042] Embodiment 3 The structural formula of the carbon forming agent described in Embodiment 3 is:

[0043]

[0044] The preparation method is: add 250ml of water and 29.72g (0.1mol) triglycidyl isocyanurate to a 500ml four-neck flask equipped with a stirrer, a thermometer, a constant temperature dropping funnel and a high-efficiency reflux condenser, start stirring, and drop Add 6.11g (0.1mol) of ethanolamine, after dripping, raise the temperature to 30°C, and keep it warm for 1.5h to make the pH of the reaction solution reach 7-8; then add 13.52g (0.1mol) of dithiobiuret, add Control the temperature in the process not to exceed 50°C, and then reflux for 8 hours to make the pH of the solution reach 7 to 8. After cooling, filter with suction (solvent recovery), wash with water, dry and pulverize to obtain the product CFA-3; The yield is 96.4%, and the decomposition temperature of 1% thermogravimetric loss is 265.4°C. The structure of the product is confirmed by FTIR and N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com