Two-block low molecular polymer-grafted nano-silicon dioxide particles, preparation method and polyester

A nano-silica, low-molecular technology, applied in the field of linear polyester, can solve the problems of decreased polyester material strength, local stress concentration, poor uniformity, etc. The effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

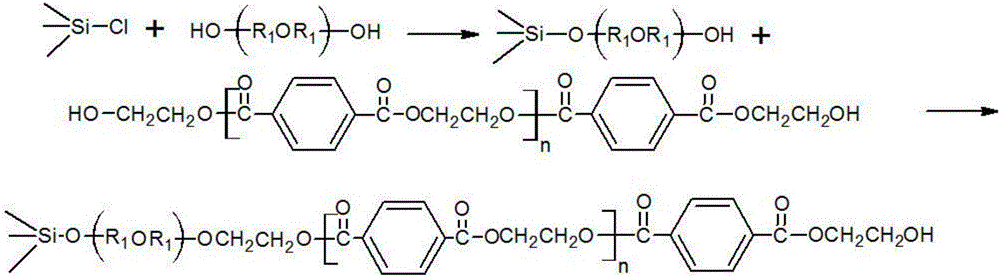

[0025] Such as figure 1 As shown, the present invention discloses a method for grafting nano-silica with two-block low-molecular polymers, comprising the following steps:

[0026] Nano-silica modified with flexible polyether segments on the surface: first dissolve 3 grams of nano-silica in 25 ml of benzene, then react with 25 ml of thionyl chloride under nitrogen protection at 65 degrees Celsius for 4 hours. Chlorine atoms are introduced into the surface of silicon oxide to pre-activate the hydroxyl groups on the surface of nano silicon dioxide. Then 2 grams of pre-activated nano silicon dioxide was dissolved in 20 milliliters of toluene, and 20 milliliters of soft polyalcohol segment was added under magnetic stirring, and the surface soft polyol segment was obtained after reacting for 5 hours under nitrogen protection and 65 degrees Celsius. Modified nano-silica, in which the hydroxyl group at the end of the soft polyol segment dehydrates and condenses with the silicon hydro...

Embodiment 2

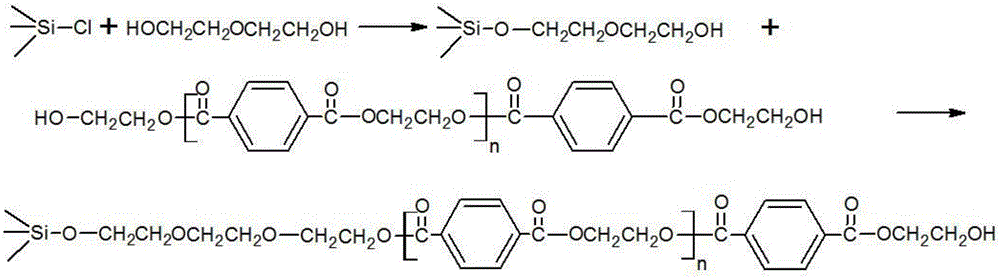

[0032] Such as figure 2 As shown, the present invention discloses a method for grafting nano-silica with two-block low-molecular polymers, comprising the following steps:

[0033] Nano-silica modified with flexible polyether segments on the surface: Dissolve 5 grams of nano-silica in 30 ml of benzene, then react with 30 ml of thionyl chloride under nitrogen protection at 65 degrees Celsius for 4 hours, Chlorine atoms are introduced into the surface of silicon oxide to pre-activate the hydroxyl groups on the surface of nano silicon dioxide. Then 1 gram of preactivated nano-silica was dissolved in 15 milliliters of toluene, 25 milliliters of triethylene glycol was added under magnetic stirring, and the surface soft polyol was obtained after reacting for 4 hours under nitrogen protection and 65 degrees Celsius. Segment-modified nano-silica, during which the hydroxyl groups at the end of the soft polyol segment dehydrate and condense with the silicon hydroxyl groups on the surfa...

Embodiment 3

[0037] Experimental purpose and method: In order to study the influence of two-block low-molecular polymer grafted nano-silica particles on the crystallization kinetics of linear polyester crystallization, this example uses the two-block low-molecular polymer synthesized in Example 2 Grafted nano-silica was used as the experimental object to study its influence on the crystallization kinetics of linear polyester chips. Standard samples were made in the injection molding machine. The melting temperature in the blender is 290°C, and the mold temperature in the injection molding machine: 50°C for pure linear polyester, and changed to 40°C after adding the two-block low-molecular polymer grafted nano-silica synthesized in Example 2. A total of seven groups of samples of synthetic two-block low-molecular polymer grafted nano-silica 0%, 1.0%, 2.0%, 3.0%, 4.0%, 5%, and 6% were prepared for mechanical properties, thermal properties, flow Tests for denaturation, etc.

[0038] Experim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com