Volute structure provided with composite lining

A composite material, volute technology, used in coatings, liquid fuel engines, components of pumping devices for elastic fluids, etc. Compressor reliability, reduced efficiency of pumps, fans and compressors to reduce gas or liquid flow resistance, improve operational efficiency and reliability, and reduce roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

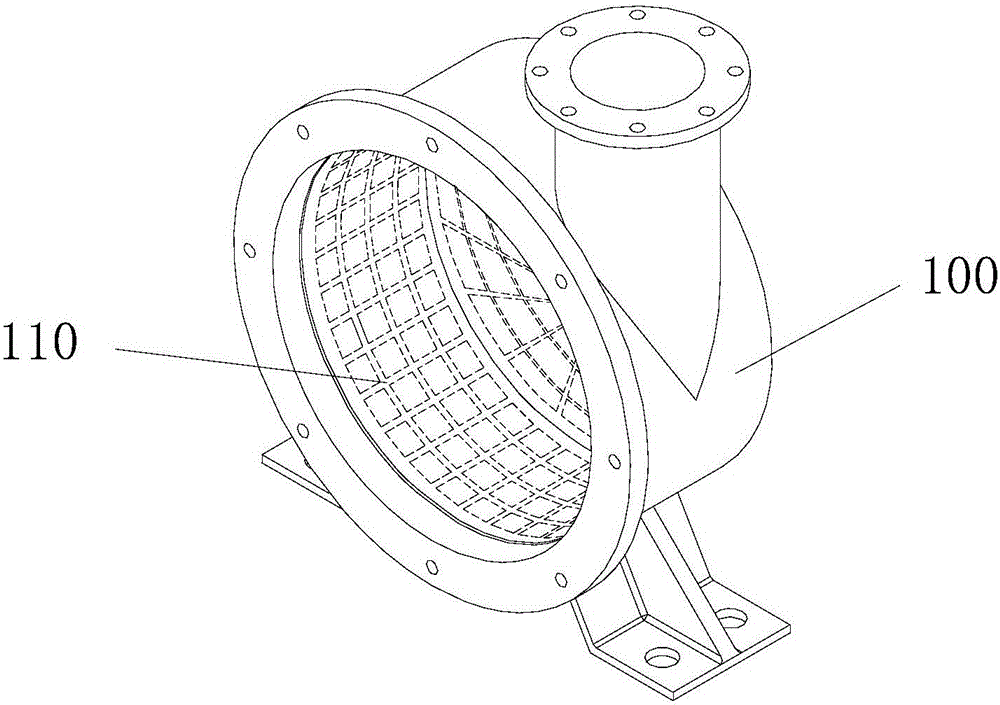

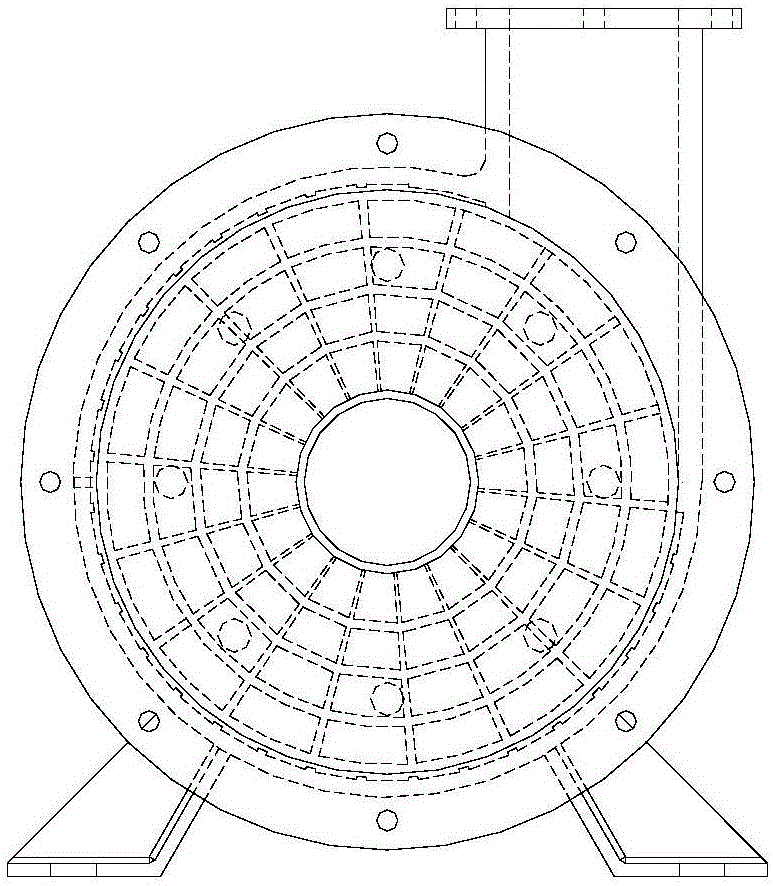

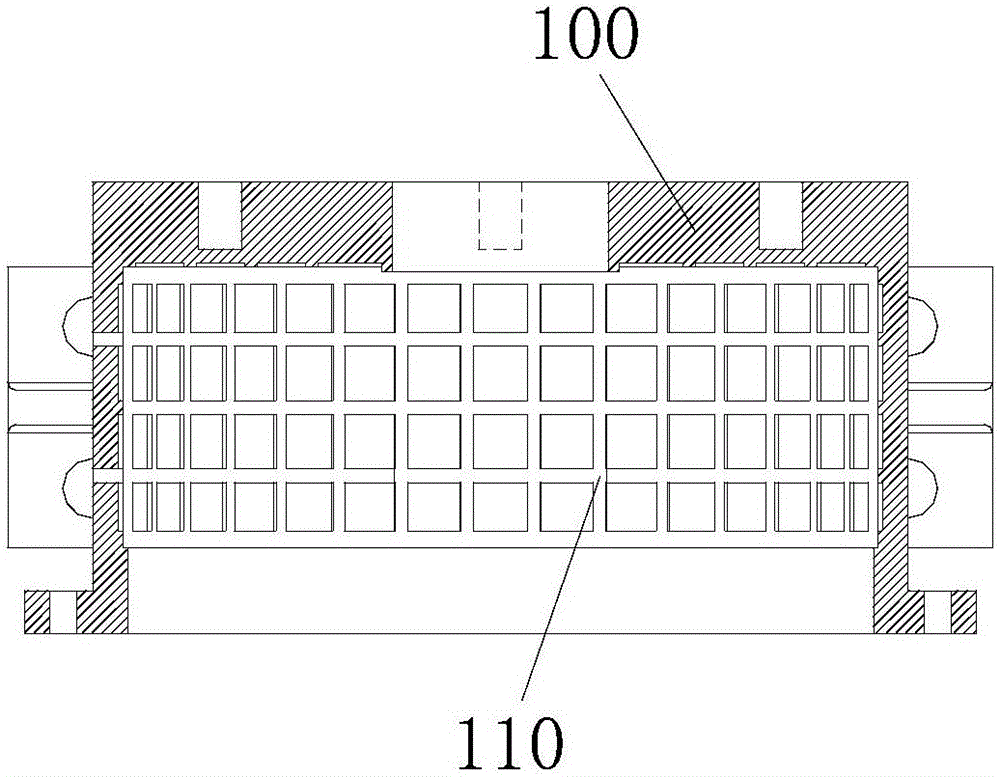

[0043] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention discloses a volute structure provided with a composite material lining 120 , and the volute structure is composed of a volute base 100 and a composite material lining 120 . The volute base 100 is manufactured by traditional casting, machining or sheet metal processing. The liner is made of polymer composite material, which is bonded with the volute base 100 by polymer resin. The volute base 100 has grid-like ribs 110 , which strengthen the polymer lining and prevent the polymer lining from being deformed, degummed and peeled off, and sliding relative to the volute base 100 . The thickness of the polymer composite material liner 120 is about 2-4 mm, and it is made of polymer resin glue as a matrix, adding chopped carbon fiber and other materials; compared with steel materials, the surface roughness of the polymer resin material is relatively low. Adding chopped carbon fiber can strengt...

Embodiment 2

[0045] The invention also discloses a method for manufacturing a volute structure with a composite material liner 120. The volute with a composite material liner 120 manufactured by this method is used in pumps, fans and compressors, which can significantly reduce internal Gas or liquid flow resistance, improving the efficiency and reliability of pumps, fans and compressors, such as Figure 5 As shown, the specific steps of the method are as follows:

[0046] Step S1: Combine Figure 1 to Figure 4 As shown, according to the shape and structure requirements of the volute, the shell of the volute base 100 is designed, and a gap of 2-4 mm is designed at the part where the cavity is formed between the shell of the volute and the impeller, and the gap is used to form a composite lining 120; in addition, a grid-shaped reinforcing rib 110 with a thickness of 1-2 mm is designed at the same time, and the shape and size of other parts of the volute remain unchanged.

[0047] Step S2: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com