Soluble textile recovery, regeneration and recycle technology

A technology of textiles and technology, applied in the field of recovery, regeneration and recycling of dissolvable textiles, can solve the problems of waste of resources, short length, low value, etc., and achieve the effect of easy identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

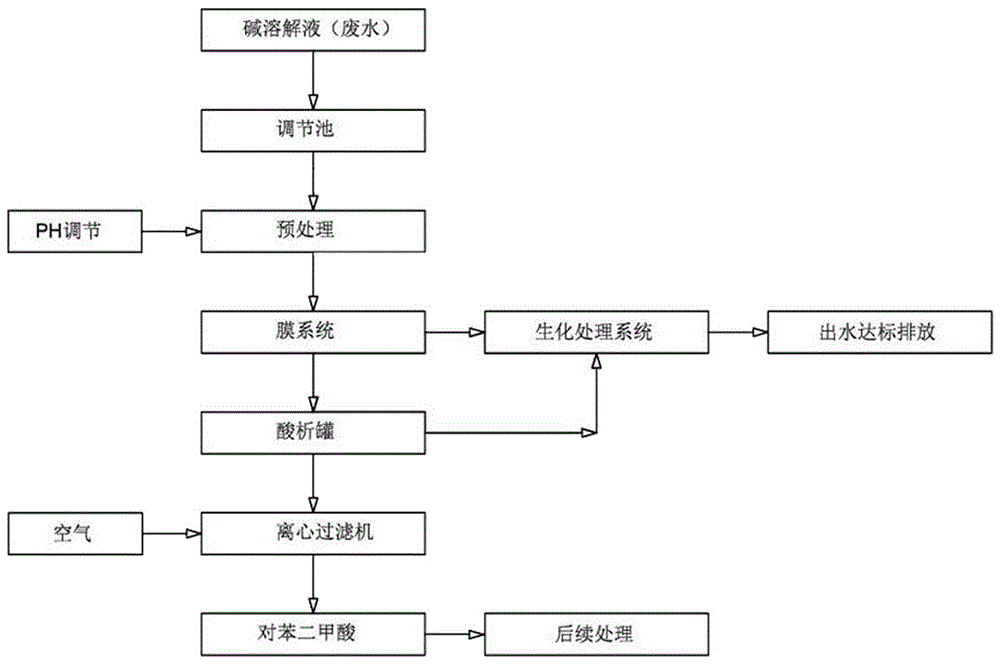

Image

Examples

Embodiment 1

[0041] Embodiment 1, 100% controllable soluble fiber fabrics and dissolving, recycling and recycling technology of soluble clothing accessories, which includes the following process steps, specifically:

[0042] a, in the polyester raw material polymerization process, add the 5-sodium sulfonate-polyethylene glycol isophthalate and the isophthalic acid of 4% by the total weight of the polymer, beating and stirring And heat up to 230°C at the same time; then move to the reactor and add polyethylene glycol with a total polymer weight of 10% to dilute it and cool it down to 210°C; continue to add polyethylene glycol to the reactor, this Part of the polyethylene glycol accounts for 10% of the total weight of the polymer. The polyethylene glycol is added within 50 minutes and stirred at the same time. The temperature is raised to 230°C under normal pressure and the mixed material is polymerized in a vacuum state. The alkali after polymerization is degraded. Finally, the slices are c...

Embodiment 2

[0049] Embodiment 2, the fiber fabric of the blended yarn fabric of controllable soluble fiber and cellulose fiber and the dissolution, recovery and reuse technology of soluble clothing accessories, which includes the following process steps, specifically:

[0050] a, the controllable soluble short fiber prepared in Example 1 is blended with cellulose fiber (such as cotton, hemp and artificial fiber), the blending ratio is 65 / 35, 50 / 50, etc.; the yarn count is conventional Cellulose fiber or blended yarn specifications; weaving according to conventional processes; dyeing with reactive dyes and disperse dyes in two baths of polyester and cellulose fibers; thus, fabrics, including woven and knitted fabrics;

[0051] 1. After the above-mentioned staple fiber blended yarn is plyed and threaded, it can be used as sewing thread for such textiles;

[0052] 2. The above-mentioned garments and textiles are paired with apparel accessories, which are hard soluble apparel accessories that...

Embodiment 3

[0056] Embodiment 3, controllable dissolving, recycling and recycling technology of blended yarn of soluble fiber and cellulose fiber plus spandex fiber fabric and soluble clothing accessories, which includes the following process steps, specifically:

[0057] a. The polymerized raw material prepared in Example 1 is subjected to a conventional spinning process to produce short fibers (3.6cn / dtex strength, 25% elongation at break) with a length of 38mm and a fineness of 1.5D, which will be controllable Soluble fiber short fiber, blended with cellulose fiber (such as cotton, hemp and artificial fiber), the blending ratio is 65 / 35, 50 / 50, etc., the yarn is interwoven with spandex or parallel elastic yarn, according to the conventional weaving process Woven or knitted fabrics; polyester and cellulose fibers are dyed with reactive dyes and disperse dyes in two baths; thus, fabrics, including woven and knitted fabrics, are sewn into finished textiles;

[0058] 1. After the above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com