Method and device for post-treatment of polymer emulsions

A technology of polymer emulsion and polymer, which is applied in the field of polymer chemistry, can solve the problems of irregular shape of polymer resin powder particles, inability to remove impurities efficiently, and influence on product appearance, and achieve simple and practical equipment, good appearance, and appearance. good form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

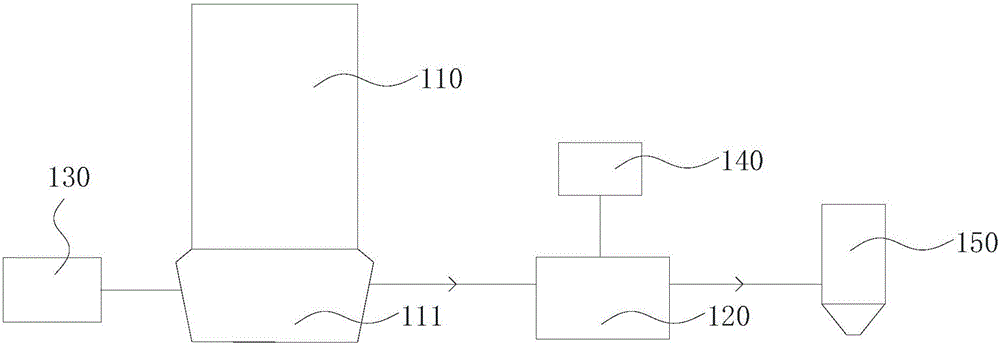

[0037] Please refer to figure 1 , this embodiment provides an equipment for post-treatment of polymer emulsion, which includes a prilling tower 110 and a neutralization tank 120 .

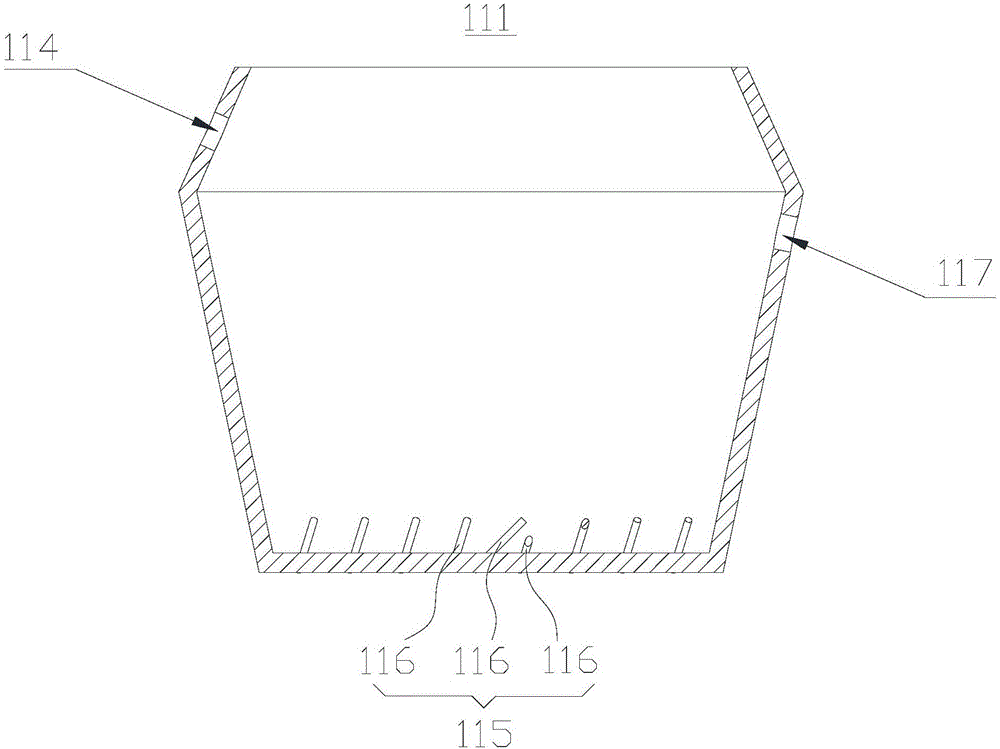

[0038] Such as figure 1 As shown, the prilling tower 110 is a hollow cylindrical structure as a whole, including a drying chamber (not shown) for drying the polymer emulsion. The nozzle (not shown in the figure), the polymer emulsion passing through the nozzle will be dispersed into fine droplets and suspended in the drying chamber. refer to figure 2 As shown, a plurality of flushing nozzle groups 112 arranged along the length direction of the prilling tower 110 are arranged on the tower wall surrounding the drying chamber, and the plurality of flushing nozzle groups 112 are arranged at equal intervals. It should be noted that, in other preferred embodiments of the present invention, the distances between the plurality of flushing nozzle groups 112 may not be completely equal, and may also be s...

Embodiment 2

[0046] The present embodiment adopts the equipment provided in the first embodiment to propose a kind of MBS resin, and its aftertreatment method is as follows:

[0047] The MBS emulsion with a solid content of 35-42% prepared by emulsion polymerization is selected. The MBS emulsion is transported to the prilling tower 110 by a delivery pump for pre-drying and granulation. The pressure of the delivery pump is set to 3.0Mpa, the inlet temperature of the prilling tower is 160°C, and the outlet temperature is 60°C. The content of the MBS powder after granulation The amount of water is 23%.

[0048] The above-mentioned MBS powder is transported from the prilling tower 110 to the pickling chamber 111 containing sulfuric acid solution for acidification and washing, and water vapor is kept flushing in the prilling tower 110 and the pickling chamber 111. Wherein, the pH of the sulfuric acid aqueous solution is 3.5, and the temperature is 60°C. The acidified and washed MBS powder is ...

Embodiment 3

[0050] This embodiment proposes a kind of MBS resin, its post-treatment method is basically the same as that of the first embodiment, the difference is: the water content of the MBS powder after granulation is 20%; the acidic solution selected is a sulfuric acid solution with pH=2.0 , the temperature is 65°C; the selected alkaline solution is sodium hydroxide solution with pH=8.2; the neutralized suspension pH=6.5~6.8, the temperature is between 45~50°C; the water content of the crude MBS resin is 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com