Camellia seed handmade soap and preparation method thereof

A handmade soap, camellia seed technology, applied in chemical instruments and methods, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as irritation, human injury, environmental pollution, etc., achieve excellent skin care, no irritation or toxic effects, production safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

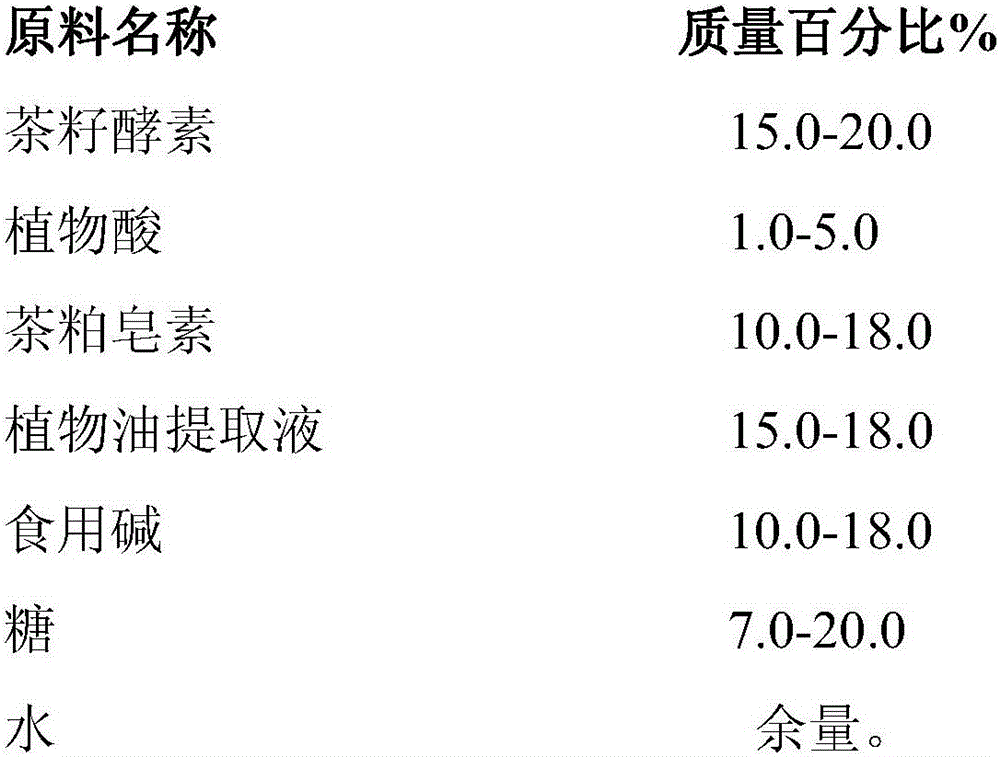

Method used

Image

Examples

Embodiment 1

[0028] Take 3g of baking soda and 10g of potassium hydroxide and slowly dissolve in water to obtain lye; add 10g of tea oil extract, 5g of olive oil extract, 20g of tea seed enzyme, 18g of tea meal saponin, and 1g of plant acid into the reaction tank , heating and melting, and slowly stirring, when the temperature rises to 60-75 ° C, slowly add the lye in step 1 to the reaction tank to form a soap, then wait for the reaction to completely saponify, and naturally cool down; the saponified soap is cooled to After 40-45°C, slowly add to the manual model to form.

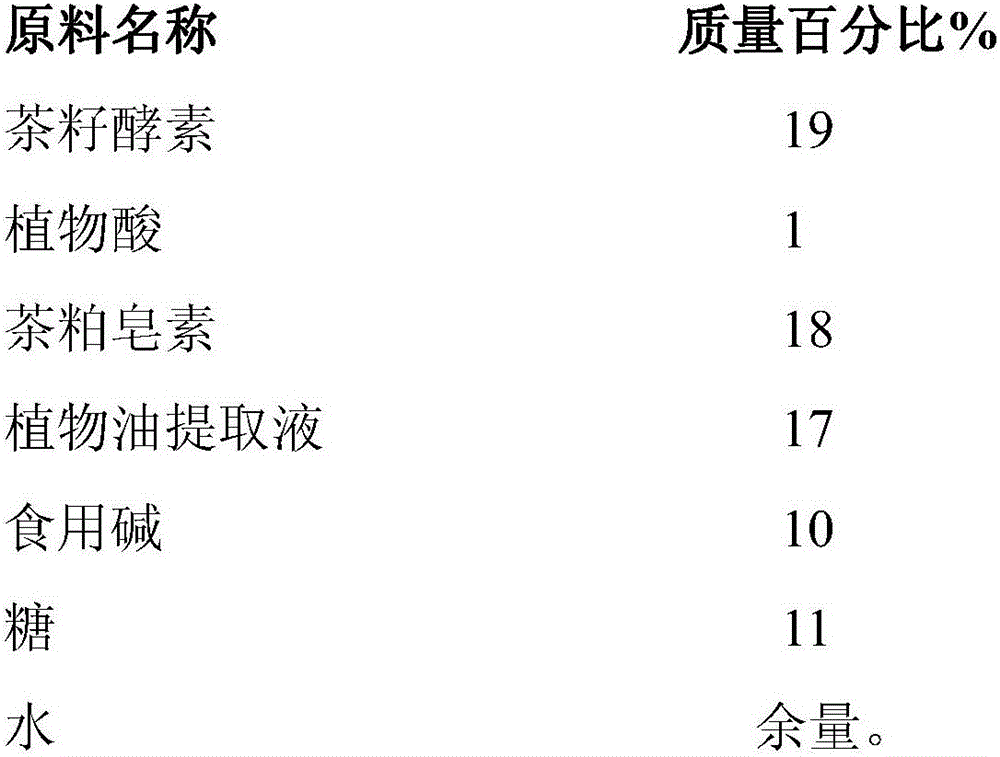

Embodiment 2

[0030] Take 12g of potassium hydroxide and slowly add water to dissolve it to obtain lye; add 16g of camellia seed oil extract, 20g of tea seed enzyme, 18g of tea meal saponin, and 1.2g of plant acid into the reaction tank, heat to melt, and stir slowly , when the temperature rises to 60-75°C, slowly add the lye in step 1 to the reaction tank to form a soap liquid, and then wait until the reaction is completely saponified, and then cool down naturally; after the saponified soap liquid cools to 40-45°C, slowly Add to shape by hand model.

Embodiment 3

[0032] Take 5g of soda ash and 9g of potassium hydroxide and slowly add in water to dissolve to obtain lye; add 5g of camellia seed oil extract, 6g of olive oil extract, 5g of sesame oil extract, 18g of tea seed enzyme, 16g of tea leaf saponin, and 1.0g of plant Add the acid into the reaction tank, heat to melt, and stir slowly. When the temperature rises to 60-75°C, slowly add the lye in step 1 to the reaction tank to form a soap liquid, and then wait until the reaction is completely saponified, and cool down naturally; saponification After cooling down to 40-45°C, the final soap solution is slowly added to the manual model for molding.

[0033] The handmade soap prepared by the invention has the appearance of light yellow transparent solid, the pH in 10% aqueous solution is 7.5-8.0, the solubility is good, and the solubility is not affected by temperature.

[0034] The invention does not contain preservatives, formaldehyde, and heavy metal ions, has no allergy, teratogenic, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com