Preparation method of chitosan membrane

A technology of chitosan film and chitosan, applied in the field of preparation of chitosan film, can solve the problem of low mechanical strength of chitosan film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

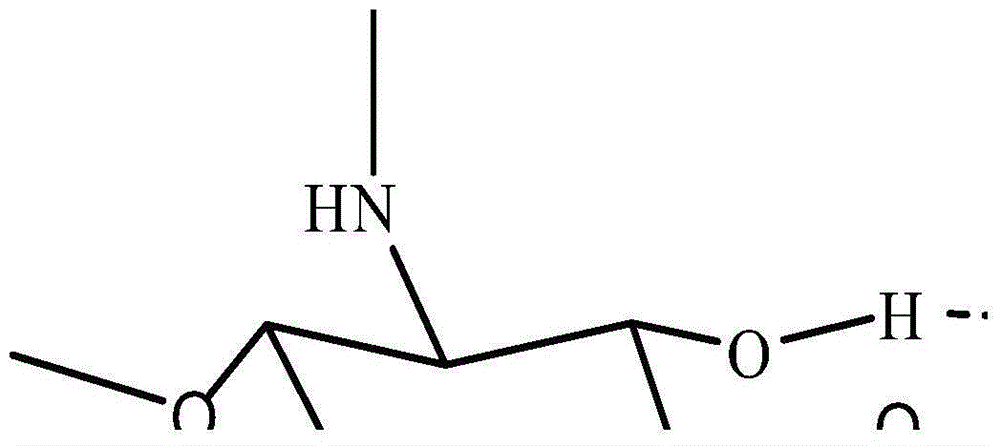

Image

Examples

Embodiment 1

[0017] Prepare 1.5% 1-carboxymethyl-3-methylimidazolium chloride salt ionic liquid aqueous solution 50g, 0.75g chitosan is completely dissolved in the above-mentioned solvent, make the chitosan film-making stoste that concentration is 1.5%, through Squeeze and filter, stand for defoaming, spin coating on glass plate, dry at 50% constant temperature at 40°C and constant humidity, soak in 2.0% sodium hydroxide solution for 2.5h to remove the film, wash with distilled water until neutral, and keep at constant temperature at 40°C and constant humidity 50% drying and other operations to obtain a transparent chitosan film, the thickness of which is 3.35 μm, the breaking strength is 171 MPa, the breaking elongation is 3.97%, and the initial modulus is 3.39 GPa.

Embodiment 2

[0019] Prepare 2.0% 1-carboxymethyl-3-methylimidazolium chloride salt ionic liquid aqueous solution 50g, 1.25g chitosan is completely dissolved in the above-mentioned solvent, make the chitosan membrane stock solution that concentration is 2.5%, through Squeeze and filter, stand for defoaming, spin coating on glass plate, dry at 50% constant temperature at 40°C and constant humidity, soak in 1.5% sodium hydroxide solution for 3.5h to remove the film, wash with distilled water until neutral, and keep at constant temperature at 40°C and constant humidity 50% drying, etc., to obtain a transparent chitosan film with a thickness of 3.22 μm, a breaking strength of 177 MPa, a breaking elongation of 4.01%, and an initial modulus of 3.47 GPa.

Embodiment 3

[0021] Prepare 3.0% 1-carboxymethyl-3-methylimidazolium chloride salt ionic liquid aqueous solution 50g, 1.0g chitosan is completely dissolved in the above-mentioned solvent, make the chitosan membrane stock solution that concentration is 2.0%, through Squeeze and filter, stand for defoaming, spin coating on glass plate, dry at 50% constant temperature and humidity at 40°C, soak in 2.0% sodium hydroxide solution for 3.0h to remove the film, wash with distilled water until neutral, and keep at constant temperature and humidity at 40°C 50% drying and other operations to obtain a transparent chitosan film with a thickness of 3.14 μm, a breaking strength of 180 MPa, a breaking elongation of 3.92%, and an initial modulus of 3.54 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com