Carbon heating low-temperature cigarette compound atomization agent, preparing method and application of same

A low-temperature cigarette, carbon heating technology, used in applications, tobacco, processing tobacco, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

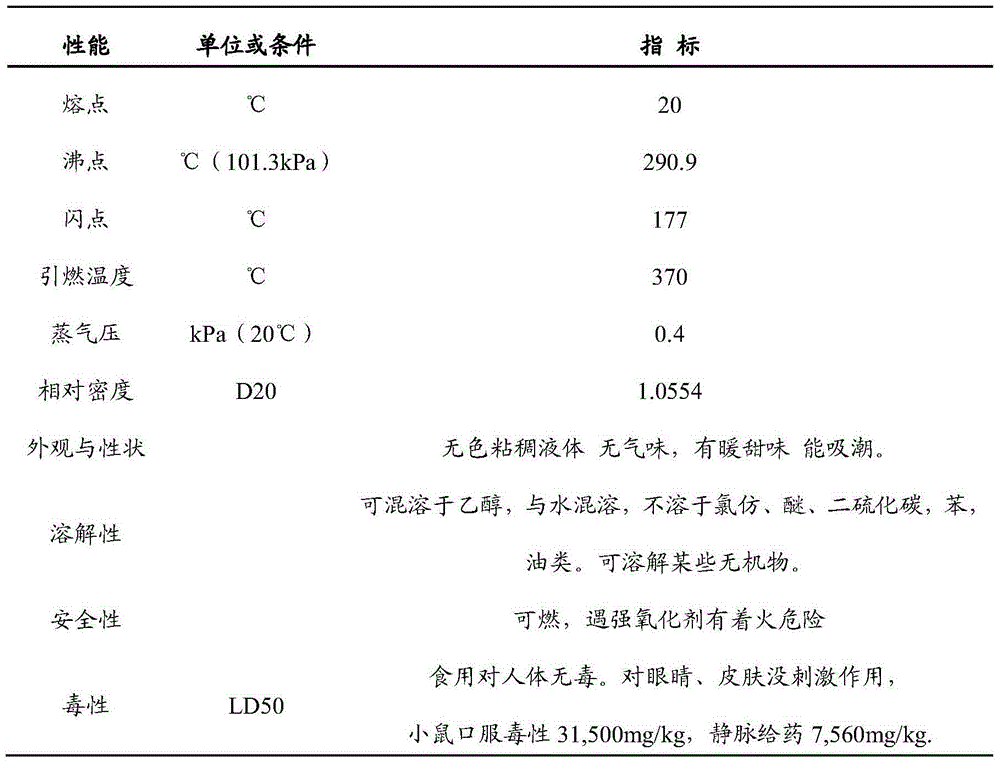

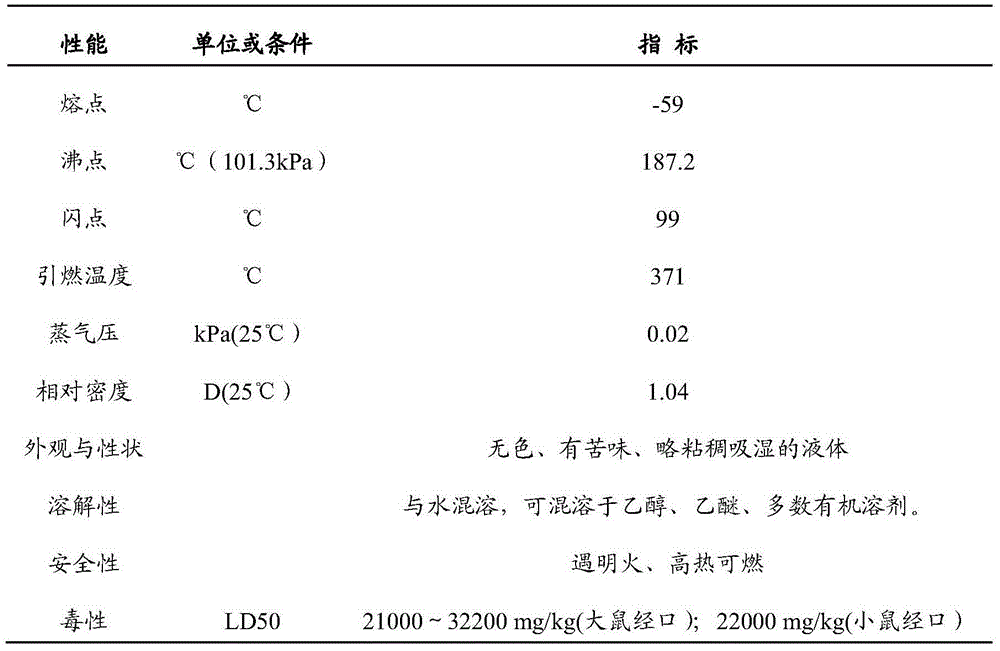

[0119] Composite atomizing agent 1, its preparation method is as follows:

[0120] 1) Weigh 5g of 1,2-propanediol, 50g of glycerin, 2g of agar (food grade), 0.02g of sodium benzoate, 0.05g of tobacco flavor and fragrance and 50g of pure water;

[0121] 2) Heat the water, add agar to the hot water and heat to 85-95°C and stir to form a homogenate state; then add tobacco flavors and fragrances, sodium benzoate, glycerin, and 1,2-propylene glycol to the homogenate in sequence; and Stir evenly under the condition of 85-95°C to obtain the composite atomizing agent 1.

Embodiment 2

[0123] Composite atomizer 2 preparation method is basically the same as that of Example 1, the difference is:

[0124] The raw materials of composite atomizer 2 are composed of 5g of 1,2-propanediol, 50g of glycerin, 0.32g of gellan gum (food grade), 0.02g of sodium benzoate, 0.05g of tobacco flavor and fragrance and 50g of pure water .

Embodiment 3

[0126] The preparation method of composite atomizing agent 3 is basically the same as that of Example 1, except that:

[0127] The raw materials of composite atomizer 3 are 5g of 1,2-propanediol, 50g of glycerin, 0.8g of agar (food grade), 0.2g of gellan gum, 0.02g of sodium benzoate, 0.05g of tobacco flavor and fragrance and 50g of pure water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com