A kind of self-sharpening diamond grinding wheel and preparation method thereof

A diamond grinding wheel and self-sharpening technology, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of long dressing time and high dressing cost of diamond grinding wheels, and improve self-sharpening and service life. High processing efficiency, solve the effect of long dressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

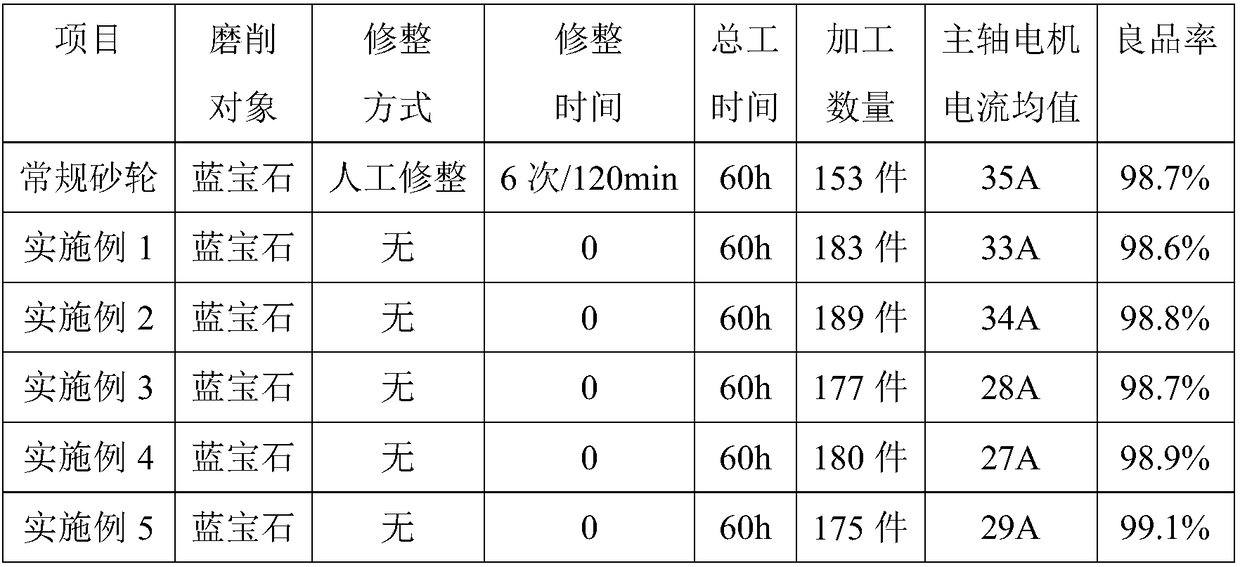

Examples

Embodiment 1

[0041] The self-sharpening diamond grinding wheel of the present embodiment comprises a grinding wheel substrate and an abrasive block, and the abrasive block is made of the following raw materials in mass percentage: Cu 28%, Sn 12%, Co 30%, Al 5%, Fe 3%, Cr 2%, Ti 2%, MoS 2 3%, SG abrasive 2%, diamond 10%, additive 3%.

[0042] Described additive is made from the raw material of following mass percent: Bi 2 o 3 35%, B 2 o 3 35%, ZnO 10%, SiO 2 5%, Al 2 o 3 3%, Na 2 CO 3 2%, Li 2 CO 3 4%, MgCO 3 2%, CaF 2 4%.

[0043] The preparation method of described additive comprises the following steps:

[0044] 1) Take Bi of formula quantity 2 o 3 , B 2 o 3 , ZnO, SiO 2 、Al 2 o 3 、Na 2 CO 3 , Li 2 CO 3 , MgCO 3 After mixing evenly, put it into a quartz crucible, place it in a high-temperature resistance furnace, heat it at 10°C / min to 1250°C and keep it warm for 2 hours to obtain a mixture;

[0045] 2) Cool the mixture obtained in step 1) to 850°C at a ...

Embodiment 2

[0053] The self-sharpening diamond grinding wheel of the present embodiment comprises a grinding wheel substrate and an abrasive block, and the abrasive block is made of the following raw materials in mass percentage: Cu 44%, Sn 10%, Co 25%, Al 3%, Fe 2%, Cr 1%, Ti 3%, MoS 2 1%, SG abrasive 5%, diamond 5%, additive 1%.

[0054] Described additive is made from the raw material of following mass percent: Bi 2 o 3 25%, B 2 o 3 40%, ZnO 5%, SiO 2 2%, Al 2 o 3 8%, Na 2 CO 3 1%, Li 2 CO 3 3%, MgCO 3 5%, CaF 2 1%.

[0055] The preparation method of described additive comprises the following steps:

[0056] 1) Take Bi of formula quantity 2 o 3 , B 2 o 3 , ZnO, SiO 2 、Al 2 o 3 、Na 2 CO 3 , Li 2 CO 3 , MgCO 3 After mixing evenly, put it into a quartz crucible, place it in a high-temperature resistance furnace, heat it at 10°C / min to 1300°C and keep it warm for 1 hour to obtain a mixture;

[0057] 2) Cool the mixture obtained in step 1) to 850°C at a rat...

Embodiment 3

[0065] The self-sharpening diamond grinding wheel of the present embodiment comprises a grinding wheel substrate and an abrasive block, and the abrasive block is made of the following raw materials in mass percentage: Cu 25%, Sn 5%, Co 30%, Al 7%, Fe 1%, Cr 2%, Ti 1%, MoS 2 2%, SG abrasive 6%, diamond 15%, additive 6%.

[0066] Described additive is made from the raw material of following mass percent: Bi 2 o 3 30%, B 2 o 3 25%, ZnO 19%, SiO 2 10%, Al 2 o 3 2%, Na 2 CO 3 5%, Li 2 CO 3 1%, MgCO 3 3%, CaF 2 5%. The preparation method of the additive is the same as in Example 1.

[0067] The preparation method of the self-sharpening diamond grinding wheel of the present embodiment comprises the following steps:

[0068] a) Take Cu powder, Sn powder, Co powder, Al powder, Fe powder, Cr powder, Ti powder, MoS 2 powder, SG abrasive, diamond and additives, put into the three-dimensional mixer and mix for 4 hours to get the mixture;

[0069] b) the mixture obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com