Preparation method of high-entropy alloy coating layer on surface of casting

A high-entropy alloy and coating technology, which is used in metal processing equipment, transportation and packaging, etc., can solve the problems of high requirements for substrates and targets, difficulty in forming high-entropy alloy coatings, and excessive heat input. The pouring temperature is easy to control, the large-scale industrial application prospect, and the operation controllability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

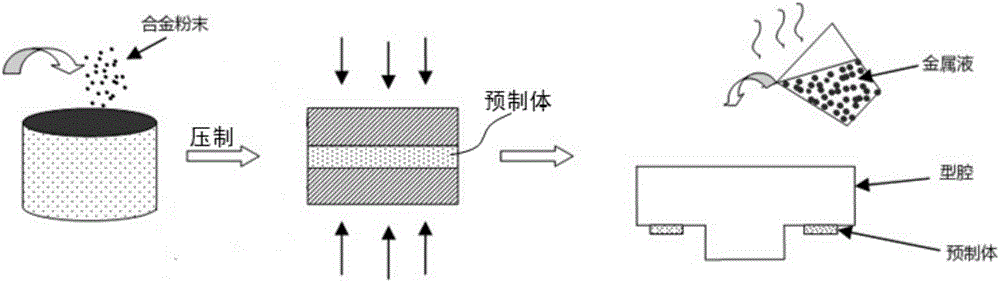

[0028] S1. Preparation of the prefabricated body: Add polyvinyl alcohol aqueous solution with a concentration of 4 to 8 wt% as a binder and add a particle size of 50 to 200 meshes through a ball mill to mix the high-entropy alloy coating powder raw material AlCrFeCoNiTi0.5 (the meaning of the molecular formula is: 0.5 represents the relative atomic ratio of Ti in the composition, and the relative atomic ratios of Al, Cr, Fe, Co, and Ni are all 1, that is, the atomic percentages of Al, Cr, Fe, Co, and Ni are all 18.18%, and the atomic percentages of Ti are percentage is 9%) mixed to form a paste, then press it into a cylindrical preform with a thickness of 4 to 5 mm and a diameter of 20 mm with a hydraulic tablet press under a pressure of 20 to 40 MPa, and then place the preform at a temperature of 60 ~120℃ vacuum drying oven for 1~3h;

[0029] S2. Modeling: Use commercially available furan resin sand, resin oil, and curing agent to mix to make a "T" type sand mold cavity, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com