A lead-free and silver-free tin bar and a preparation method thereof

A lead-free solder and tin bar technology, which is applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as difficult to guarantee soldering quality, high silver price, and many broken components, so as to reduce the production cost of enterprises , Reduce the cracking of components and reduce the effect of melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

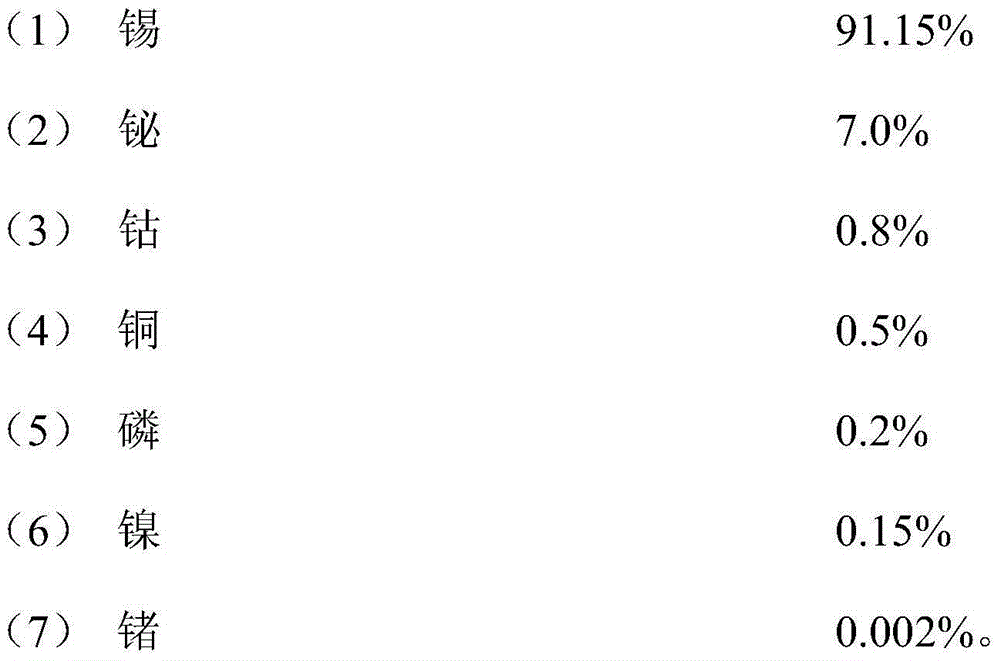

[0018] A kind of lead-free silver-free tin bar, by weight percentage, its formula consists of:

[0019]

[0020] Preparation method: first melt tin to 400°C, keep warm and stir for 25 minutes, remove tin slag after stirring, add bismuth and continue stirring for 10 minutes, add phosphorus and stir for 10 minutes, add copper, cobalt, nickel and stir for 10-15 minutes, add germanium and stir for 2- After 3 minutes, take a sample to detect that the above components are qualified, and then cool down to about 340°C to start forming a lead-free and silver-free tin bar.

Embodiment 2

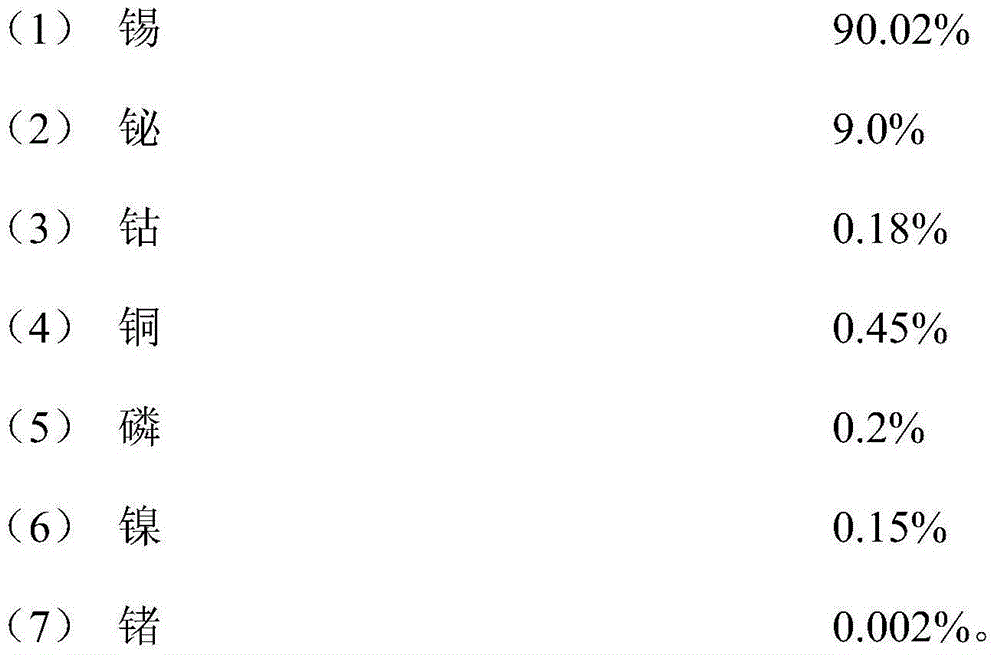

[0022] A kind of lead-free silver-free tin bar, by weight percentage, its formula consists of:

[0023]

[0024] Preparation method: first melt tin to 400°C, keep warm and stir for 25 minutes, remove the tin slag after stirring, add bismuth and continue stirring for 10 minutes, add phosphorus and stir for 10 minutes, add copper and cobalt and stir for 10-15 minutes, add germanium and stir for 2-3 minutes, Sampling is carried out to detect that the above components are qualified, and the temperature is lowered to about 340°C to form a lead-free and silver-free tin bar.

Embodiment 3

[0026] A kind of lead-free silver-free tin bar, by weight percentage, its formula consists of:

[0027]

[0028]

[0029] Preparation method: first melt tin to 400°C, keep warm and stir for 25 minutes, remove tin slag after stirring, add bismuth and continue stirring for 15 minutes, add phosphorus and stir for 10 minutes, add copper, cobalt, nickel and stir for 10-15 minutes, add germanium and stir for 2- After 3 minutes, take a sample to detect that the above components are qualified, and then cool down to about 340°C to start forming a lead-free and silver-free tin bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com