A method for preparing multi-layer coatings by thermal spraying

A multi-layer coating and thermal spraying technology, which is applied in the coating, metal material coating process, fusion spraying, etc., to achieve the effects of fewer multi-layer coating defects, high deposition efficiency, and high coating preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

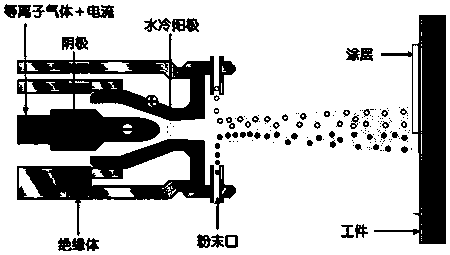

Method used

Image

Examples

Embodiment 1

[0028] Al prepared by different path powder feeding spraying 2 o 3 +TiO 2 / High chromium iron multilayer coating, Al 2 o 3 +TiO 2 (melting point is 1894°C) particle size is 300 mesh, high chromium iron powder (melting point is 1857°C) is 300 mesh. Spray distance 200mm; current 410A; voltage 320V; N 2 Flow 230L / min; Ar flow 100L / min; H 2 Flow rate 15L / min; High chromium ferro powder feeding voltage 18V; Al 2 o 3 +TiO 2 The powder feeding voltage is 8V. The moving speed of the spray gun is 6mm / s, and the thickness of the prepared coating is about 500μm; the hardness of the coating is about 950 HV, and the bonding strength reaches 95Mpa.

[0029] The Al prepared in this example 2 o 3 +TiO 2 Multi-layer coatings alternately distributed with high chromium iron, the SEM image is as follows figure 1 As shown, the high chromium iron layer and Al can be seen from the figure 2 o 3 +TiO 2 The layers are distributed alternately, there is no obvious interface between the...

Embodiment 2

[0031] Al prepared by different path powder feeding spraying 2 o 3 +TiO 2 / MgO multilayer coating, Al 2 o 3 +TiO 2 (melting point is 1894°C) particle size is 300 mesh, MgO (melting point is 2800°C) powder is 200 mesh. Spray distance 200mm; current 430A; voltage 320V; N 2Flow 230L / min; Ar flow 100L / min; H 2 Flow rate 15L / min; MgO powder feeding voltage 6V; Al 2 o 3 +TiO 2 Powder feeding voltage 15-20V. The moving speed of the spray gun is 6 mm / s, and the thickness of the prepared coating is about 500 μm. The hardness of the coating is about 950HV, and the bonding strength reaches 95Mpa.

Embodiment 3

[0033] Al prepared by different path powder feeding spraying 2 o 3 +TiO 2 / YSZ multilayer coating, Al 2 o 3 +TiO 2 (melting point is 1894°C) particle size is 300 mesh, YSZ (melting point is 2480°C) powder is 200 mesh. Spray distance 200mm; current 410A; voltage 320V; N 2 Flow 230L / min; Ar flow 100L / min; H 2 Flow rate 15L / min; YSZ powder feeding voltage 8V; Al 2 o 3 +TiO 2 The powder feeding voltage is 18V. The moving speed of the spray gun is 6 mm / s, and the thickness of the prepared coating is about 900 μm. The hardness of the coating is about 950 HV, and the bonding strength reaches 95Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com