A kind of qled device based on metal/metal oxide and preparation method thereof

A technology based on oxides and metals, applied in the field of metal/metal oxide-based QLED devices and their preparation, can solve the problems of high hole injection barriers of QLED devices, achieve the effects of reducing defect states, reducing potential barriers, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

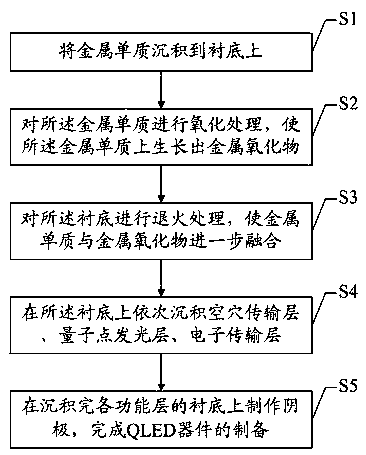

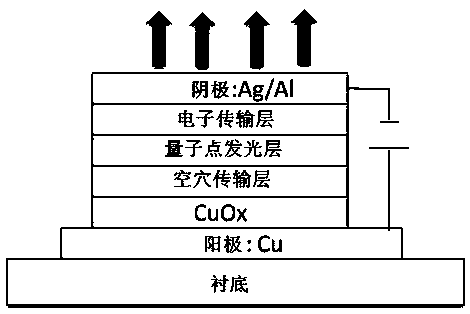

[0044] Embodiment one uses Cu / CuO x Fabrication of QLED devices with the structure as the bottom electrode

[0045] 1), using the method of steaming to deposit metal elemental Cu on the substrate, its thickness is 200nm;

[0046] 2), put the substrate part deposited with metal elemental Cu into hydrogen peroxide (use hydrogen peroxide with a volume ratio of 30%, wherein a small amount of acetic acid is added, and the volume ratio of acetic acid to the total solution is 0.02-0.1%), and the metal elemental Cu is Oxidation for 2h to control the thickness of copper oxide, making CuO x directly grown on metallic Cu. Or heating the substrate deposited with metal element Cu in oxygen to oxidize metal element Cu, the heating temperature is 300°C, and the reaction time is 1h;

[0047] 3), the substrate is annealed at a temperature of 200°C in nitrogen, and the annealing time is 20min, so that Cu and CuO x Further effect, one is to make copper oxide can be reduced in a small amount ...

Embodiment 2

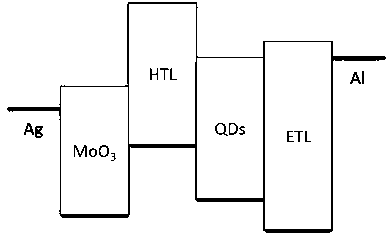

[0052] Embodiment 2 uses Mo / MoO x Fabrication of QLED devices with the structure as the bottom electrode

[0053] 1), Mo is deposited on the substrate by the method for magnetron sputtering, and its thickness is between 150nm;

[0054] 2), then put the substrate part deposited with metal elemental Mo into hydrogen peroxide (use 30% hydrogen peroxide by volume, wherein a small amount of acetic acid is added, and acetic acid accounts for 0.02-0.1% by volume of the total solution) to oxidize the metal elemental Mo 1h, to control the thickness of molybdenum oxide, so that copper oxide grows directly on the metal elemental Cu. Or oxidize the metal elemental Mo by heating it in oxygen, the heating temperature is 250°C, and the reaction time is 1h;

[0055] 3) Anneal the substrate grown on molybdenum oxide at 250°C in nitrogen, and the annealing time is 15min, which can make Mo and MoO x Further function, one is to make molybdenum oxide a small amount of reduction to generate oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com