Mineral powder suppressant and preparing method thereof

A technology of mineral powder and dust suppressant, which is applied in the field of polymer hydrosol dust suppressant and its preparation, can solve the problems of less than 30% dust suppression efficiency, the need to improve the dust suppression efficiency, the difficulty of wetting of fine particles, and the like. Adhesion probability and consolidation effect, good environmental safety, effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

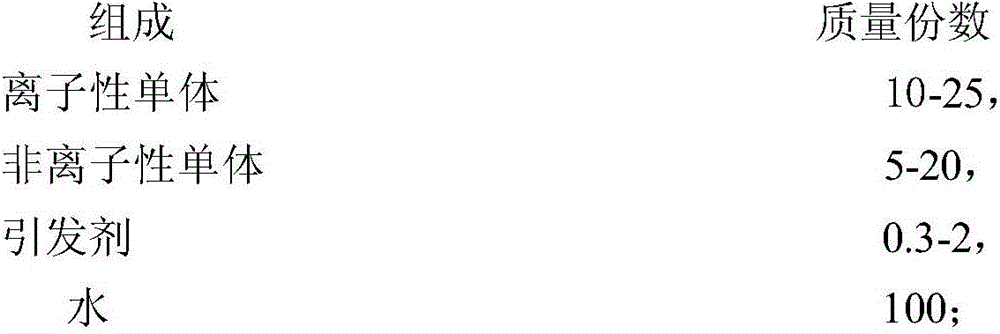

Method used

Image

Examples

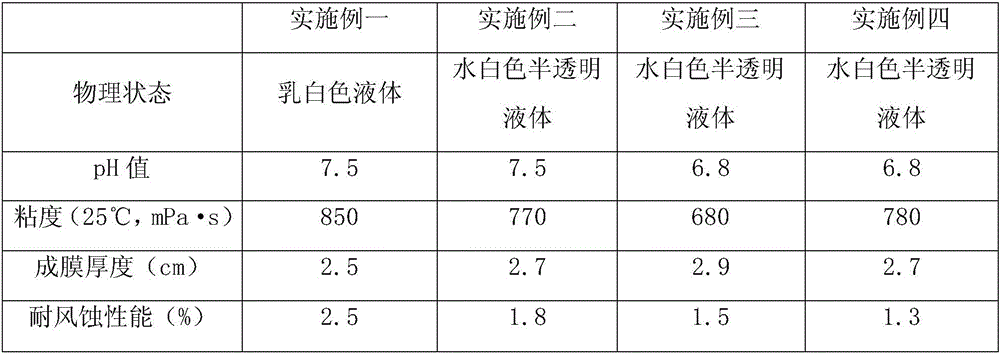

Embodiment 1

[0033] The parts by mass are calculated in grams. 10g of acrylic acid is used as an ionic monomer, 15g of butyl acrylate and 5g of hydroxyethyl acrylate are used as a nonionic monomer, and they are uniformly mixed as a raw material solution for later use. Add 100g of distilled water to a reactor equipped with a stirrer, a thermometer, a dropping funnel and a nitrogen conduit, replace with nitrogen for 40 minutes with the help of stirring, raise the temperature of the water bath to 80°C, and continuously add the aforementioned raw material mixture dropwise to control the progress of dropping , The dropwise addition was completed in 3.0 hours. Meanwhile, 8 g of ammonium persulfate aqueous solution with a mass concentration of 5% was added dropwise (time synchronization). The temperature of the system was raised to 90°C and kept for 1.5 hours. The system is lowered to room temperature, and the pH value of the above reaction system is adjusted to 7.5 with sodium hydroxide with a ...

Embodiment 2

[0037] The implementation steps are the same as in Example 1, except that: as an ionic monomer, 10 g of acrylic acid is replaced by 8 g of methacrylic acid and 20 g of sodium vinylsulfonate aqueous solution (10%); the polymerization reaction temperature is 85° C.

[0038] The performance evaluation method is the same as in Example 1.

Embodiment 3

[0040] The parts by mass are calculated in grams, 10g of acrylic acid is used as an ionic monomer, 5g of butyl acrylate, 8g of styrene and 7g of hydroxypropyl acrylate are used as a nonionic monomer, and they are uniformly mixed as a raw material solution for later use. Add 100g of distilled water to a reactor equipped with a stirrer, a thermometer, a dropping funnel and a nitrogen conduit, replace with nitrogen for 40 minutes with the help of stirring, raise the temperature of the water bath to 80°C, and continuously add the aforementioned raw material mixture dropwise to control the progress of dropping , the dropwise addition was completed within 3.0 hours. Meanwhile, 10 g of a mass concentration of 5% potassium persulfate aqueous solution was added dropwise at the same time. The temperature of the system was raised to 90°C and kept for 1.5 hours. The system was cooled down to room temperature, and the pH value of the above reaction system was adjusted to 6.8 with 5.0% sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com