High-efficiency production method of chlorinated polyethylene with high elongation

A technology of chlorinated polyethylene and high elongation, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of not getting higher elongation CPE, increasing energy consumption and time cost, and excessive washing water consumption, etc. Problems, to meet the strength and toughness, reduce energy consumption and time cost, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

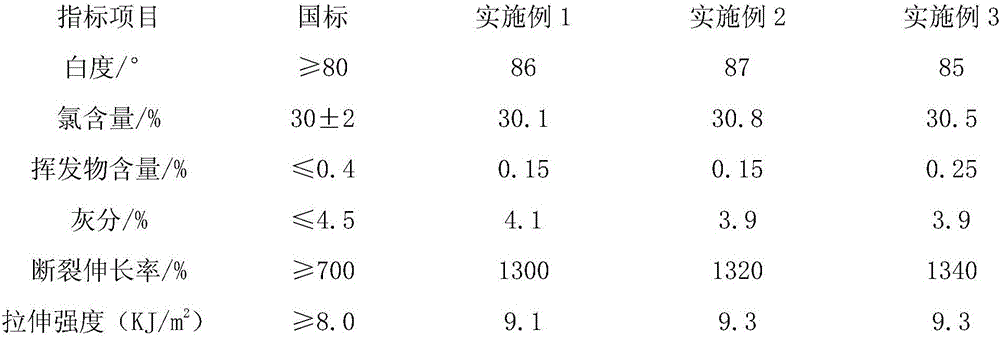

Examples

Embodiment 1

[0051] A high-efficiency production method for preparing high-elongation chlorinated polyethylene, comprising the steps of chlorination reaction, water washing and filtration, primary centrifugation, leaching, secondary centrifugation, and drying, specifically:

[0052] The water of 800 parts by weight, the polyethylene of 110 parts by weight, the emulsifier of 0.15 parts by weight and the dispersant of 4 parts by weight are put into reactor; Polyethylene is dispersed in water, and then the temperature is raised to 110°C. During the heating process, 23wt.% of the total amount of chlorine gas is introduced for chlorination reaction; the temperature is then raised from 110°C to 137°C, and the total amount of chlorine gas of 22wt.% is introduced during the heating process. The chlorine gas is used for chlorination reaction; the temperature is stabilized at 137±0.5°C, and the remaining chlorine gas is introduced for chlorination reaction; the total amount of chlorine gas is 1.15 ti...

Embodiment 2

[0055] A high-efficiency production method for preparing high-elongation chlorinated polyethylene, comprising the steps of chlorination reaction, water washing and filtration, primary centrifugation, leaching, secondary centrifugation, and drying, specifically:

[0056] The water of 900 parts by weight, the high-density polyethylene of 138 parts by weight, the emulsifier of 0.25 parts by weight and the dispersant of 6.5 parts by weight are put into reactor; ℃ to disperse polyethylene in water, and then raise the temperature to 110°C. During the heating process, 18wt.% of total chlorine gas is introduced to carry out the chlorination reaction; .% chlorine gas for chlorination reaction; stabilize the temperature at 137±0.5°C, feed the remaining chlorine gas for chlorination reaction; the total amount of chlorine gas is 1.2 times the weight of polyethylene, and the reaction time is about 4 hours. The emulsifier is 0.15 parts by weight of polyoxyethylene ether and 0.1 parts by wei...

Embodiment 3

[0059] A high-efficiency production method for preparing high-elongation chlorinated polyethylene, comprising the steps of chlorination reaction, water washing and filtration, leaching, centrifugation, and drying, specifically:

[0060] The water of 900 parts by weight, the high-density polyethylene YEC-5305T of 125 parts by weight, the emulsifier of 0.20 parts by weight and the dispersant of 5 parts by weight are put into reactor; Add the initiator of 0.20 parts by weight under stirring condition and Raise the temperature to 75°C to disperse polyethylene in water, then raise the temperature to 110°C, and feed chlorine gas with a total amount of 19wt.% chlorine gas during the heating process to carry out the chlorination reaction; The amount of chlorine gas is 20wt.% chlorine gas for chlorination reaction; the temperature is stabilized at 137±0.5°C, and the remaining chlorine gas is introduced for chlorination reaction; the total amount of chlorine gas is 1.18 times the weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com