Method for preparing mullite honeycomb ceramic carrier with all crystal whisker structure

A technology of honeycomb ceramic carrier and mullite, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of high environmental hazards and toxicity, and achieve good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

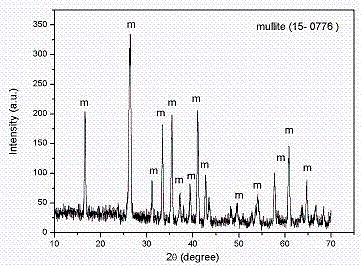

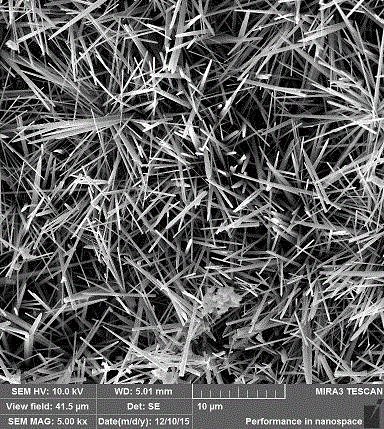

[0019] Example 1: Add 200g ceramic powder to 200ml water, wherein Al 2 o 3 , silicon dioxide, aluminum fluoride and molybdenum trioxide mass ratio is 68:26:3:3; Stir for 30min to obtain a uniformly dispersed ceramic slurry; add acetic acid to adjust the pH value to 1.5 in the ceramic slurry, then pour the ceramic slurry into the mold, and add glutaraldehyde that accounts for 0.6wt% of the total mass of the ceramic slurry as The initiator was left to stand at room temperature for 0.5 hours to be cured and molded, and then demoulded. The sample after demoulding was dried in an oven at 60°C for 12 hours, and then moved into a muffle furnace to raise the temperature to 1500°C at a rate of 5°C / min. 2h; The microstructure of the obtained mullite porous ceramics with full whisker structure is shown in the attached figure 2 ; The XRD pattern of the mullite honeycomb ceramic carrier held at 1500°C for 2h is shown in figure 1 .

Embodiment 2

[0020] Example 2: Add 300g ceramic powder to 200ml water, wherein Al 2 o 3 , silicon dioxide, aluminum fluoride and vanadium pentoxide in a mass ratio of 68:26:3:3; and add chitosan accounting for 0.5wt% of the total mass of the powder, and the resulting mixture is stirred magnetically at room temperature Stir with a mixer for 30 minutes to obtain a uniformly dispersed ceramic slurry; add acetic acid to the ceramic slurry to adjust the pH value to 2, then pour the ceramic slurry into the mold, and add 0.6wt% of glutaraldehyde as an initiator The agent was left to stand at room temperature for 1 hour to be cured and then demoulded. The demoulded sample was dried in an oven at 60°C for 12 hours, then moved into a muffle furnace and heated to 1500°C at a rate of 5°C / min, and kept for 2 hours. ; The microstructure of the obtained mullite porous ceramics with full whisker structure is as attached image 3 , the XRD pattern of the mullite honeycomb ceramic carrier held at 1500°C f...

Embodiment 3

[0021] Example 3: Add 300g ceramic powder to 200ml water, wherein Al 2 o 3 , silicon dioxide, aluminum fluoride mass ratio is 73:21:6; and add chitosan accounting for 0.5wt% of the total powder mass, the obtained mixture is stirred with a magnetic stirrer at room temperature for 30min, to obtain evenly dispersed Ceramic slurry; add acetic acid to adjust the pH value to 2 in the ceramic slurry, then pour the ceramic slurry into the mold, and add glutaraldehyde accounting for 0.6wt% of the ceramic slurry as an initiator, and leave it standing at room temperature for 1.5 After hours of curing and molding, the demoulded sample was dried in an oven at 60°C for 12 hours, then moved into a muffle furnace to raise the temperature to 1500°C at a rate of 5°C / min, and held for 2 hours. The porosity of the obtained full-whisker structured mullite honeycomb ceramic carrier was 77%, and the compressive strength was 16 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com