Bone repair composite for inducing mesenchymal stem cell differentiation and preparing method of bone repair composite

A composite material and mesenchymal stem cell technology, applied in the field of bone repair composite materials that induce mesenchymal stem cell differentiation and its preparation, can solve problems such as unsatisfactory biological properties, achieve good physical and chemical properties, reduce agglomeration effects, and promote adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

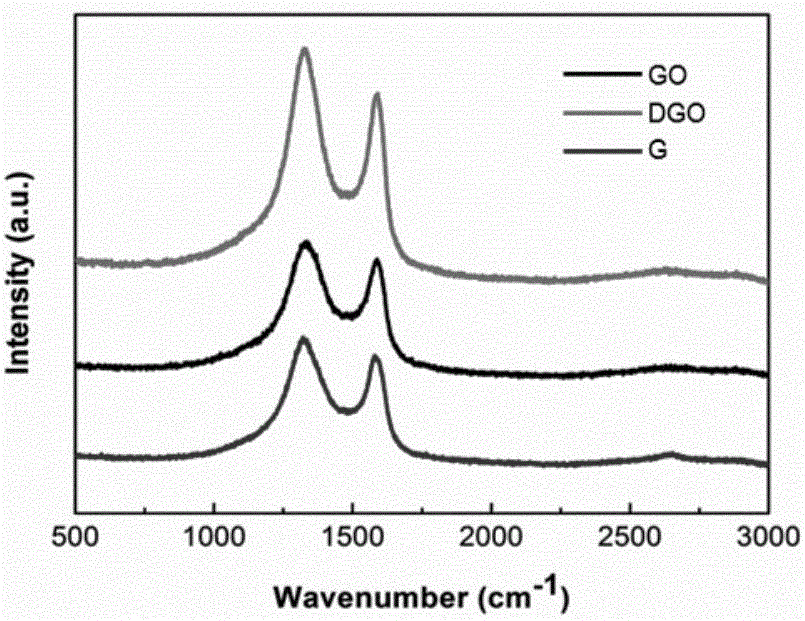

[0039] (1) Preparation of graphene oxide (GO)

[0040]Graphite oxide was successfully obtained by the optimized Hummers method, and uniformly dispersed single-layer or few-layer graphene oxide was obtained by ultrasound. The specific method is:

[0041] Mix natural flake graphite and sodium nitrate in a ratio of 2:1, add 230ml of concentrated sulfuric acid, then add potassium permanganate in ice bath, stir, and keep the reaction temperature below 20°C. Remove the ice bath, keep warm in a water bath at 35°C for 30 minutes, then slowly add 460ml of deionized water, wait until the reaction temperature drops to 70°C, and bathe at the same temperature for 10 minutes. Then add 700ml of hydrogen peroxide to terminate the reaction. Suction filtration, repeated washing and centrifugation of the obtained yellow-brown filtrate until the pH of the supernatant is about 7, and drying to obtain graphite oxide.

[0042] Ultrasonic separation: Mix graphite oxide and deionized water at a rat...

Embodiment 2

[0053] Steps (1), (2), (3) are the same as in Example 1.

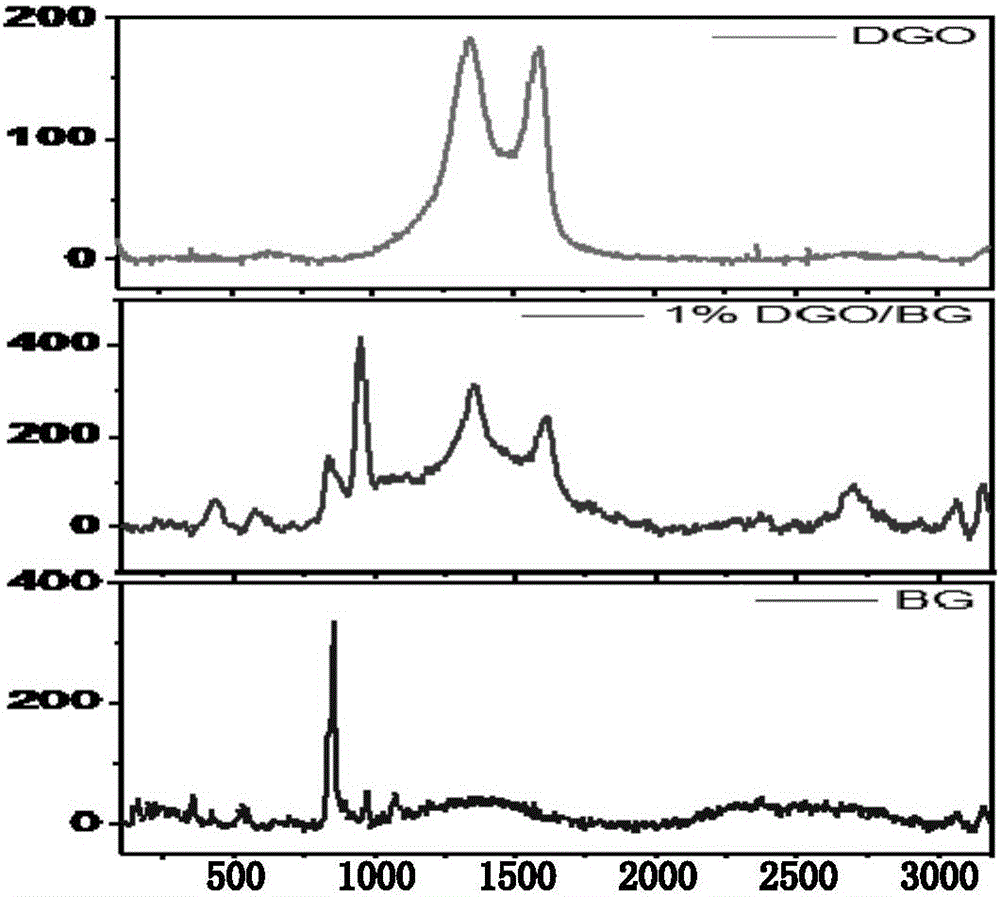

[0054] (4) Graphene oxide / bioactive glass composite (DGO / BG) prepared by sol-gel method

[0055] The DGO / BG composite material with 1wt.% DGO was prepared by the sol-gel method. The preparation process was as follows: the experiment used ethyl orthosilicate (TEOS), triethyl phosphate (TEP), calcium nitrate tetrahydrate (CN), etc. 58S bioactive glass (BG) was prepared by sol-gel method. First, 0.36ml of TEP was dissolved in the mixed liquid of distilled water, absolute ethanol and ammonia water, and stirred thoroughly at 80°C for 24 hours to obtain a hydrolyzed TEP solution. Then 0.65ml TEOS and 0.35g CN were added into the TEP hydrolysis solution and stirred at room temperature for 120h to form a sol-gel solution. Weigh 0.0136 g of the DGO prepared in (3) in advance, dissolve it in dimethylformamide (DMF), and sonicate for 2 hours to form a uniform DGO suspension. The sol-gel solution was slowly added to the DGO sus...

Embodiment 3

[0060] Steps (1), (2), (3) are the same as in Example 1.

[0061] (4) Graphene oxide / bioactive glass composite (DGO / BG) prepared by sol-gel method

[0062] The DGO / BG composite material with 3wt.% DGO was prepared by the sol-gel method. The preparation process was as follows: the experiment used ethyl orthosilicate (TEOS), triethyl phosphate (TEP), calcium nitrate tetrahydrate (CN), etc., 58S bioactive glass (BG) was prepared by sol-gel method. First, 0.36ml of TEP was dissolved in the mixed liquid of distilled water, absolute ethanol and ammonia water, and stirred thoroughly at 80°C for 24 hours to obtain a hydrolyzed TEP solution. Then 0.65ml TEOS and 0.35g CN were added into the TEP hydrolysis solution and stirred at room temperature for 120h to form a sol-gel solution. Weigh 0.0415 g of the DGO prepared in (3) in advance, dissolve it in dimethylformamide (DMF), and sonicate for 2 hours to form a uniform DGO suspension. The sol-gel solution was slowly added to the DGO su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com