A kind of preparation method of non-slip industrial shoes

A technology for industrial shoes and shoes, applied in the direction of shoe-making machinery, footwear, adhesive shoe parts, etc., can solve the problems of being unable to withstand bumps, easy to wear, and reduce the service life of rubber shoes, and achieve strong oil resistance and service life. The effect of long, excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

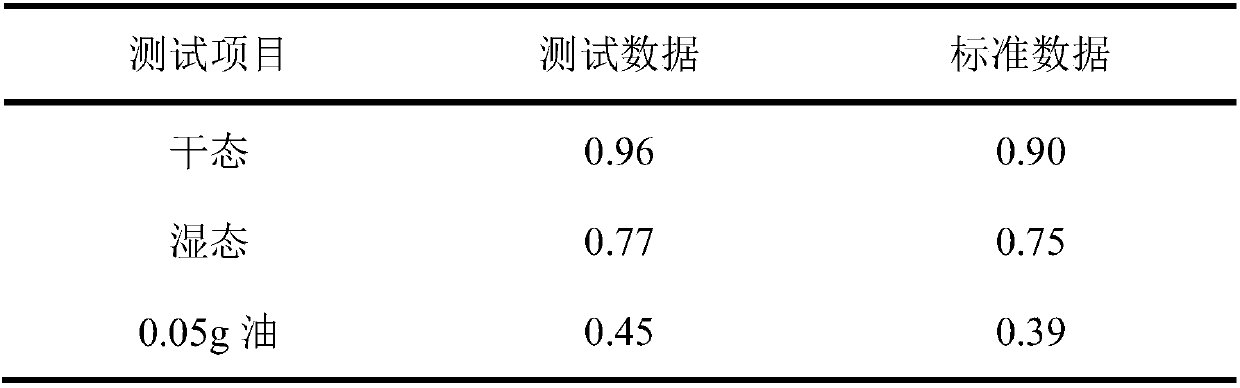

Embodiment 1

[0029] (1) Preparation of mucilage: Weigh the following components by weight: 100 parts of latex, 2 parts of antioxidant, 2 parts of accelerator CA, 1 part of accelerator BE, 2 parts of sulfur, 0.5 part of defoamer, dispersant 1 part of agent, 20 parts of pottery clay, and 15 parts of thickener; then grind the solid materials in the mortar composition into powder, and then add each raw material into the container according to the ratio to make the mortar.

[0030] (2) Preparation of rubber sheet: take the following components by weight: 15 parts of standard rubber, 10 parts of butadiene rubber, 10 parts of nitrile rubber, 10 parts of white carbon black, 25 parts of activated calcium carbonate, 2 parts of petroleum resin , 1 part of tackifying resin, 3 parts of dioctyl adipate, 1 part of antioxidant, 0.3 part of stearic acid, 1 part of polyethylene glycol, 2 parts of zinc oxide, 0.5 part of rubber vulcanization accelerator MBTS, rubber vulcanization accelerator Agent MBT 0.1 pa...

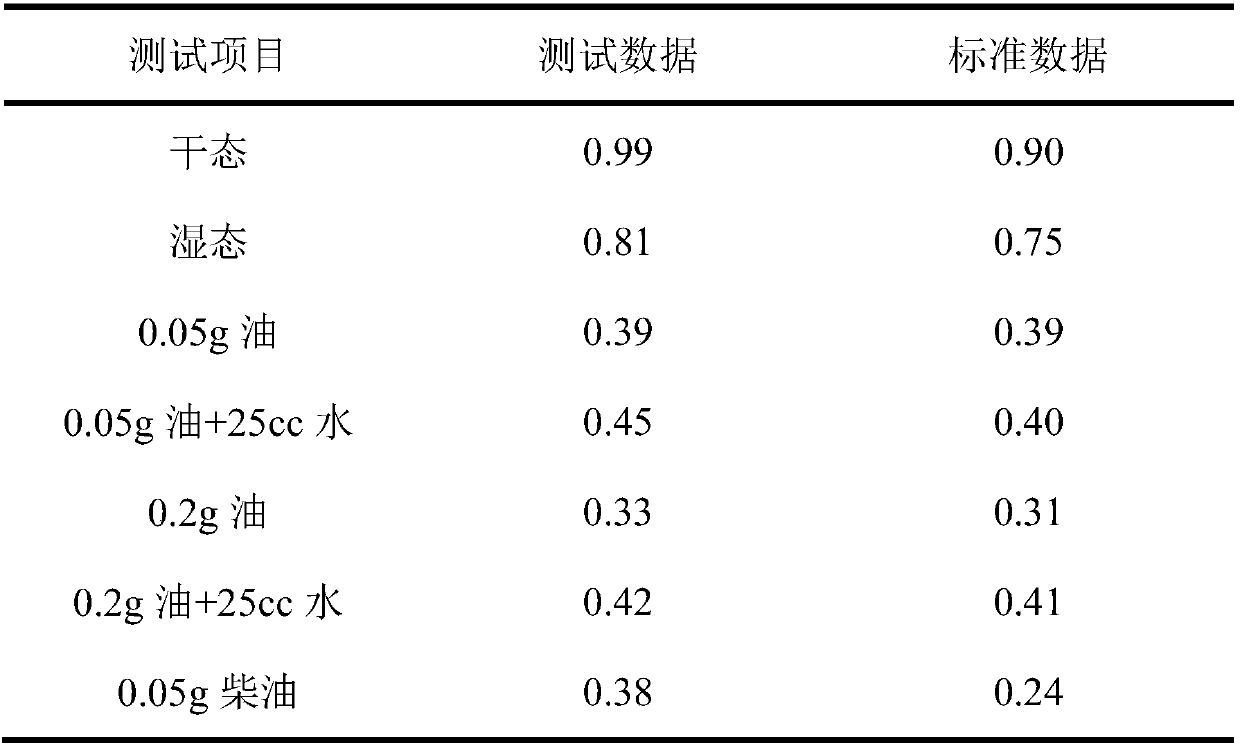

Embodiment 2

[0044] (1) Preparation of mucilage: Weigh the following components by weight: 100 parts of latex, 2 parts of antioxidant, 2 parts of accelerator CA, 1 part of accelerator BE, 2 parts of sulfur, 0.5 part of defoamer, dispersant 1 part of agent, 20 parts of pottery clay, and 15 parts of thickener; then grind the solid materials in the mortar composition into powder, and then add each raw material into the container according to the ratio to make the mortar.

[0045] (2) Preparation of rubber sheet: take the following components by weight: 20 parts of standard rubber, 15 parts of butadiene rubber, 15 parts of nitrile rubber, 15 parts of white carbon black, 30 parts of activated calcium carbonate, 2.5 parts of petroleum resin , 1.5 parts of tackifying resin, 5 parts of dioctyl adipate, 1.5 parts of anti-aging agent, 0.5 parts of stearic acid, 1.5 parts of polyethylene glycol, 3 parts of zinc oxide, 0.6 parts of rubber vulcanization accelerator MBTS, rubber vulcanization Accelerato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com