PTFE/PI composite-nanometer-fiber porous membrane and preparing method thereof

A technology of composite nanofibers and composite fiber membranes, which is applied in fiber treatment, filament/thread forming, heating/cooling fabrics, etc., can solve the problems of poor hydrophobicity and alkali resistance, and poor processing performance of polyimide. Achieve the effect of uniform density, environmental protection and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

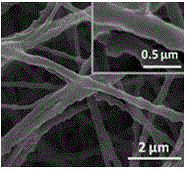

[0037] In order to solve the above problems, the invention provides a preparation method of PTFE / PI composite nanofiber porous membrane, comprising the following steps:

[0038] 1) Prepare PEO solution: dissolve PEO in deionized water, stir, and prepare PEO solution;

[0039] 2) Prepare PEO / PTFE mixed solution: add PTFE emulsion to the PEO solution described in step 1), stir and prepare PEO / PTFE mixed solution;

[0040] 3) Prepare PEO / PTFE-PAAS mixture: add PAAS and deionized water to the PEO / PTFE mixture described in step 2), stir and prepare PEO / PTFE-PAAS mixture;

[0041] 4) Preparation of PTFE / PI composite nanofiber porous membrane: PEO / PTFE-PAAS composite fiber membrane was prepared by electrospinning the PEO / PTFE-PAAS mixture, and after heat treatment, the PTFE / PI composite nanofiber porous membrane was obtained.

[0042] PTFE emulsion:

[0043] The PTFE emulsion of the present invention is an aqueous dispersion obtained by emulsion polymerization of polytetrafluoroe...

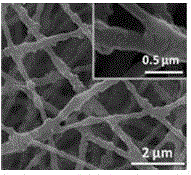

Embodiment 1

[0063] The preparation method of PTFE / PI composite nanofiber porous membrane, wherein the solution in the PEO solution contains 4 wt% of PEO, the mass ratio of PEO and PTFE in the PEO / PTFE mixed solution is 3:100, and the PAAS in the PEO / PTFE-PAAS mixed solution The mass ratio to PTFE is 2:8, and the PEO / PTFE-PAAS mixture is 18wt% PEO / PTFE-PAAS mixture; the specific steps are as follows:

[0064] The PEO powder was dissolved in deionized water at 40 °C and mechanically stirred for 3 h to obtain a PEO solution with a mass fraction of 4 wt%. Cool to room temperature and the bubbles in the solution due to rapid stirring disappear. Add the PTFE emulsion into the PEO solution, stir and prepare the PEO / PTFE mixed solution; add PAAS and deionized water into the PEO / PTFE mixed solution, stir and prepare the PEO / PTFE-PAAS mixed solution ; When the PEO / PTFE-PAAS composite nanofiber membrane was prepared by electrospinning, the voltage, collection distance and flow rate were 13 kV, 20 c...

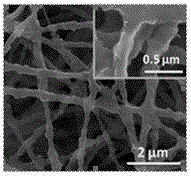

Embodiment 2

[0066] The preparation method of PTFE / PI composite nanofiber porous membrane, wherein the solution in the PEO solution contains 4 wt% of PEO, the mass ratio of PEO and PTFE in the PEO / PTFE mixed solution is 3:100, and the PAAS in the PEO / PTFE-PAAS mixed solution The mass ratio to PTFE is 1:4, and the PEO / PTFE-PAAS mixture is 18wt% PEO / PTFE-PAAS mixture; the specific steps are as follows:

[0067] The PEO powder was dissolved in deionized water at 40 °C and mechanically stirred for 3 h to obtain a PEO solution with a mass fraction of 4 wt%. Cool to room temperature and the bubbles generated by rapid stirring in the solution disappear. Add the PTFE emulsion into the PEO solution, stir and prepare the PEO / PTFE mixed solution; add PAAS and deionized water into the PEO / PTFE mixed solution, stir and prepare the PEO / PTFE-PAAS mixed solution ; When the PEO / PTFE-PAAS composite nanofiber membrane was prepared by electrospinning, the voltage, collection distance and flow rate were 13 kV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com