A method for synthesizing lithium metal oxide cathode materials using a metal fluoride flux prepared by plasma fluorination

A lithium metal oxide, cathode material technology, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of high production cost, complicated operation, poor cycle and rate performance, etc. Simple operation and the effect of improving the magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

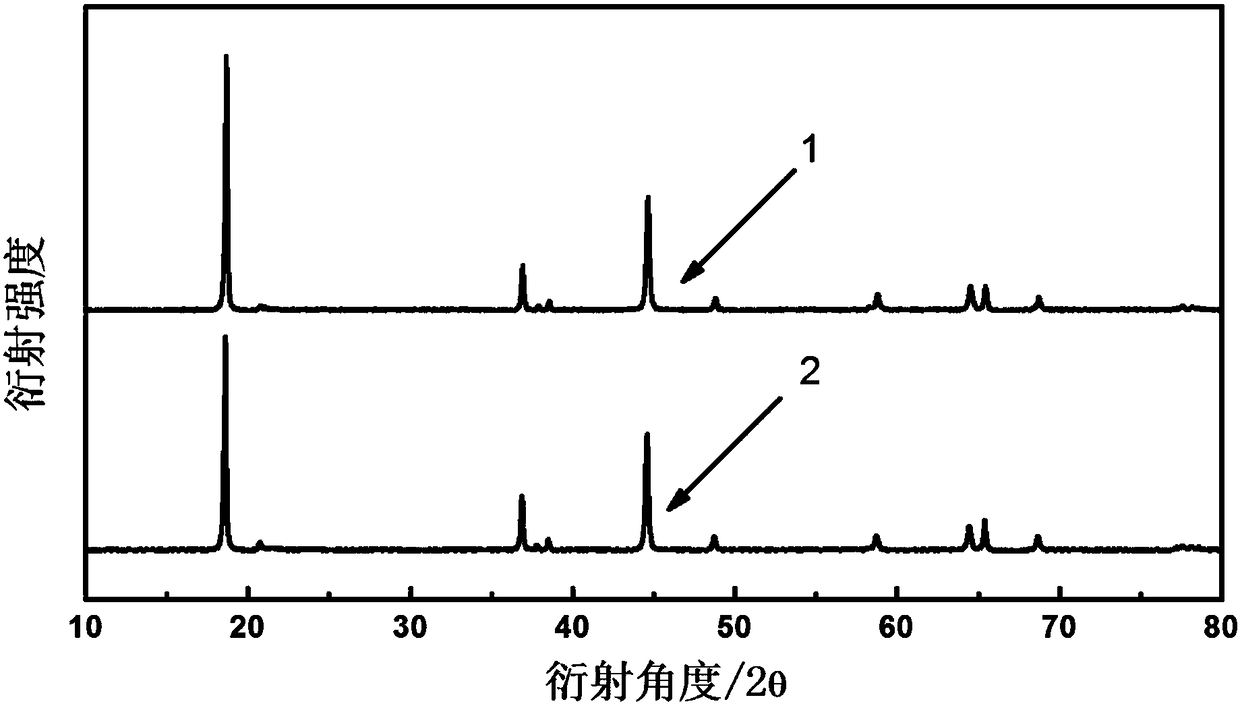

[0033] Specific Embodiment 1: The method for synthesizing lithium metal oxide positive electrode materials using the metal fluoride flux prepared by the plasma fluorination method in this embodiment is carried out according to the following steps:

[0034] 1. Dissolve the lithium metal oxide precursor material and the flux precursor in an organic solvent at a molar ratio of 1: (0.001-0.2), stir at 60°C-200°C, and evaporate the solvent to dryness to form surface adhesion The lithium metal oxide precursor material A of the flux precursor; the chemical formula of the lithium metal oxide precursor material is Ni x co y mn z m 1-x-y-z (OH) 2 or Ni x co y mn z m 1-x-y-z CO 3 , where 0≤x≤1, 0≤y≤1, 0≤z≤1, x+y+z≤1, M is Zr, Fe, Sm, Pr, Nb, Ga, Zn, Y, Mg, Al, One or more of Cr, Ca, Ti, Cu, Sr, Mo, Ce, Sn, Sb.

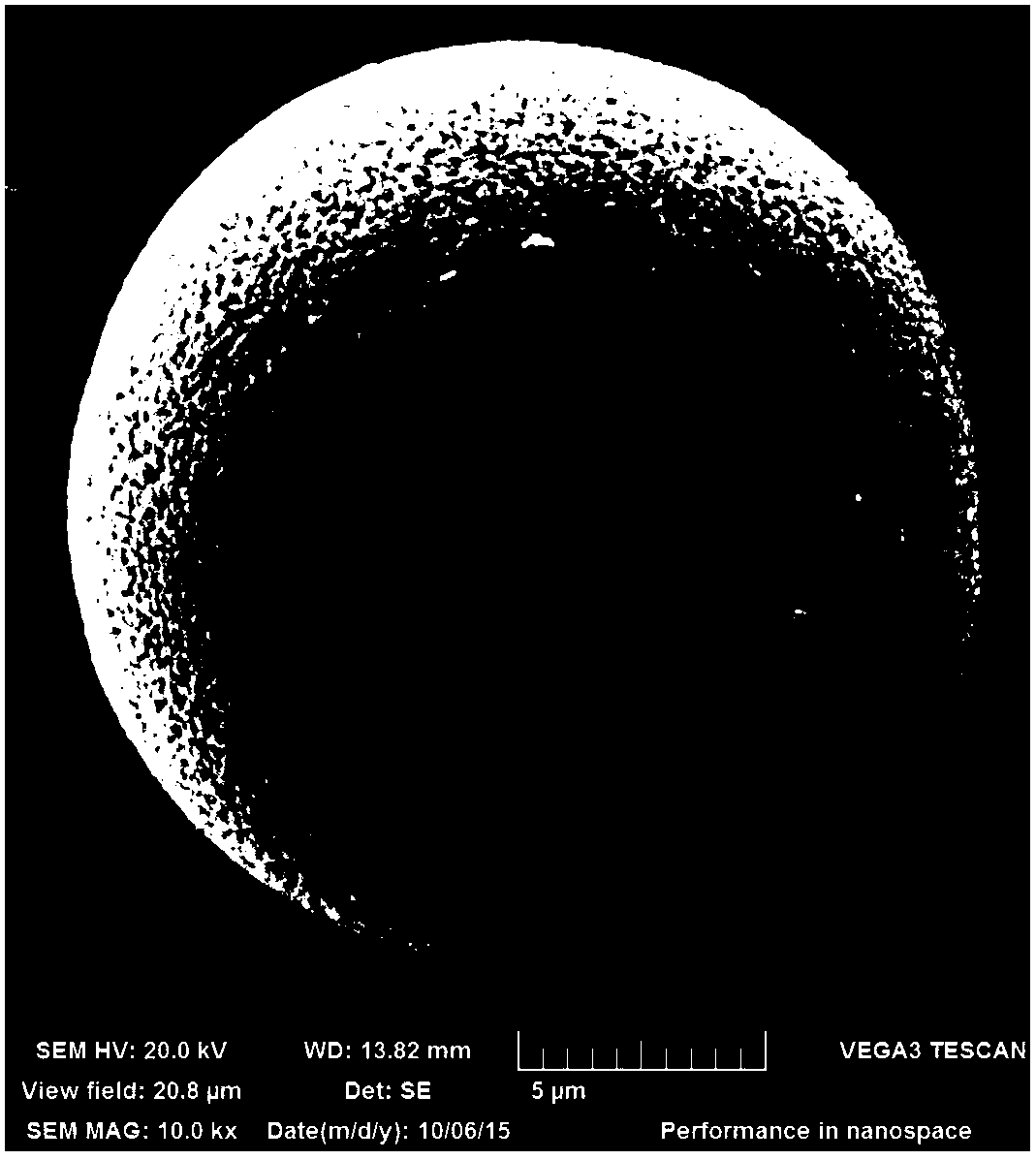

[0035] 2. Put material A into a plasma etching machine, use fluorine-containing gas for surface treatment, and prepare lithium metal oxide precursor material B with met...

specific Embodiment approach 2

[0037] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the flux precursor described in step one is sodium silicate, potassium silicate, tungsten silicate, lead silicate, bismuth silicate, barium silicate one or a mixture of several. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment is different from Embodiment 1 in that the organic solvent in Step 1 is one or a mixture of alcohols, aromatic hydrocarbons, ethers, and ketones. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com