A kind of preparation method of high rate nickel cobalt lithium aluminate cathode material

A technology of lithium nickel cobalt aluminate and cathode material, applied in battery electrodes, structural parts, electrical components, etc., can solve problems such as the inability to promote lithium ion migration rate, material rate performance is not ideal, and electronic and lithium ion conduction obstacles. , to achieve the effect of inhibiting cation mixing, improving cycle performance and rate performance, and promoting structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

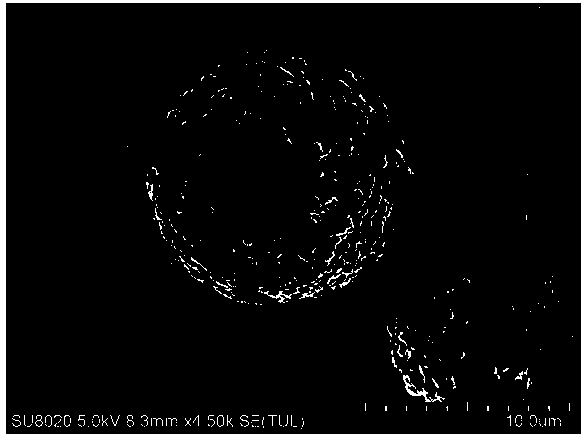

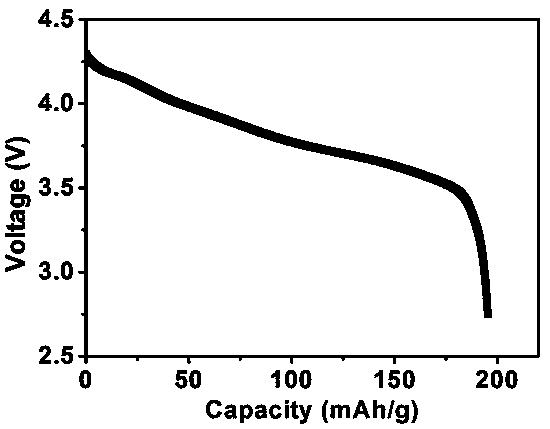

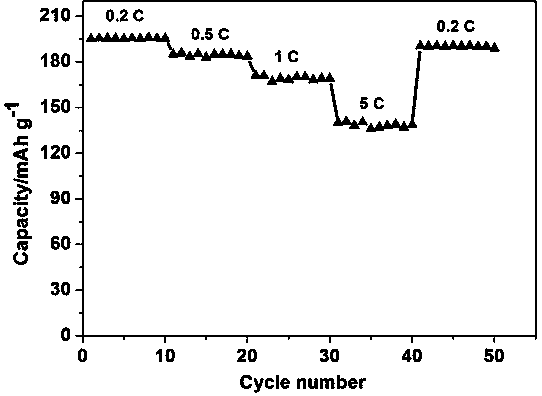

Image

Examples

Embodiment 1

[0025] The preparation method of the high-rate nickel-cobalt lithium aluminate positive electrode material in this embodiment has the following steps:

[0026] (1) Preparation of nickel-cobalt-lithium-aluminate precursor: Weigh nickel nitrate and cobalt nitrate crystals at a molar ratio of 85:15, dissolve them in water and mix them uniformly to obtain a mixed solution A with a metal ion concentration of 1.0 mol / L. Weigh 5 mol of aluminum nitrate dissolved in 2 mol / L ammonia water and 4 mol / L sodium hydroxide to prepare mixed solution B, inject mixed solution A and mixed solution B into the reaction kettle containing the bottom liquid at the same time, and control the whole reaction The pH value of the system is 11.0±0.02, the stirring speed is 500 r / min, the reaction is 12h, and the temperature is 55°C. After aging, washing and filtering, the reaction product is dried at 120°C to obtain the nickel cobalt lithium aluminate precursor Material;

Embodiment 2

[0031] The preparation method of the high-rate nickel-cobalt lithium aluminate positive electrode material in this embodiment has the following steps:

[0032] (1) Preparation of nickel-cobalt-lithium-aluminate precursor: Weigh nickel sulfate and cobalt sulfate crystals at a molar ratio of 85:15, dissolve them in water and mix them evenly. The metal ion concentration is 1.0 mol / L, and weigh 5 mol of sulfuric acid Dissolve aluminum in a mixed solution of 2 mol / L ammonia water and 4 mol / L sodium hydroxide, inject the two mixed solutions into the reaction kettle containing the bottom liquid at the same time, control the pH value of the entire reaction system at 11.5±0.02, and the stirring speed The temperature is 700 r / min, the reaction is 16 h, the temperature is 50 ° C, the reaction product is aged, washed, filtered, and dried at 100 ° C to obtain the nickel cobalt lithium aluminate precursor material;

[0033] (2) Lithium doping modification of potassium ions: the obtained nic...

Embodiment 3

[0037] The preparation method of the high-rate nickel-cobalt lithium aluminate positive electrode material in this embodiment has the following steps:

[0038] (1) Preparation of nickel-cobalt-lithium-aluminate precursor: Weigh nickel nitrate and cobalt nitrate crystals at a molar ratio of 85:15, dissolve them in water and mix them evenly. The metal ion concentration is 5.0 mol / L, and weigh 5 mol of nitric acid Aluminum is dissolved in a mixed solution of 10 mol / L ammonia water and 20 mol / L sodium hydroxide, and the two mixed solutions are injected into the reaction kettle containing the bottom liquid at the same time, and the pH value of the entire reaction system is controlled at 12.0±0.02, and the stirring speed is 800 r / min, react for 8 h, the temperature is 55 °C, the reaction product is aged, washed, filtered, and dried at 80 °C to obtain the nickel cobalt lithium aluminate precursor material;

[0039] (2) Lithium doping modification of potassium ions: the obtained nicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com