Super-strength and anti-wear artificial quartz stone plate and production method thereof

A kind of artificial quartz stone, super strong technology, applied in the field of building decoration and decoration materials, can solve the problems of brightness reduction, mechanical performance reduction, bursting, etc., and achieve the effect of expanding application fields and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

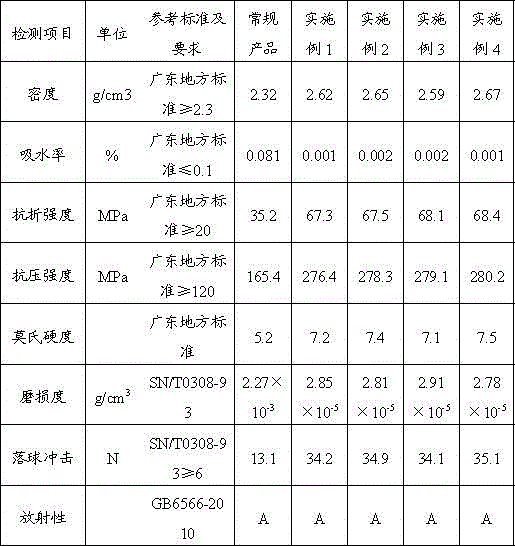

Examples

Embodiment 1

[0028] The present invention provides a super-strong, wear-resistant artificial quartz stone plate, which is made of the following components by mass: 12.3 parts of unsaturated polyester resin (the unsaturated polyester resin is composed of the following components by weight: Diacid unsaturated polyester resin 30%, phthalic acid unsaturated polyester resin 50%, tetrachlorophthalic anhydride unsaturated polyester resin 20%), chopped basalt fiber 1.2 parts (its short The cut basalt fiber consists of 65% of the chopped fiber with a length of 3mm and a diameter of 9μm and 35% of the chopped fiber with a length of 6mm and a diameter of 9μm), 3.1 parts of silicon nitride (the weight percentage of silicon nitride is below the composition: 100 mesh ~ 300 40% of the target powder and 60% of the 300 mesh to 500 mesh powder), 4.6 parts of calcium sulfate whiskers, 75.01 parts of inorganic silicon material (the inorganic silicon material is composed of the following weight percentages: 67% ...

Embodiment 2

[0034] The present invention provides a super strong, wear-resistant artificial quartz stone plate, which is made of the following parts by mass: 13.1 parts of unsaturated polyester resin (the unsaturated polyester resin is composed of the following weight percentages: Diacid unsaturated polyester resin 44%, phthalic acid unsaturated polyester resin 37%, tetrachlorophthalic anhydride unsaturated polyester resin 19%), chopped basalt fiber 1.6 parts (its short The cut basalt fiber consists of 74% of the chopped fiber with a length of 3mm and a diameter of 9μm and 26% of the chopped fiber with a length of 6mm and a diameter of 9μm), 3.8 parts of silicon nitride (the weight percentage of silicon nitride is below the composition: 200 mesh ~ 300 Target powder 30% and 300 mesh ~ 500 mesh powder 70%), 5.3 parts of calcium sulfate whiskers, 71.76 parts of inorganic silicon material (the inorganic silicon material is composed of the following weight percentages: 70~325 mesh quartz powder ...

Embodiment 3

[0040] The present invention provides a super-strong, wear-resistant artificial quartz stone plate, which is made of the following parts by mass: 11.7 parts of unsaturated polyester resin (the unsaturated polyester resin is composed of the following weight percentages: Diacid unsaturated polyester resin 48%, phthalic acid unsaturated polyester resin 25%, tetrachlorophthalic anhydride unsaturated polyester resin 27%), chopped basalt fiber 1.8 parts (its short The cut basalt fiber consists of 82% of chopped fibers with a length of 3mm and a diameter of 9μm and 18% of chopped fibers with a length of 6mm and a diameter of 9μm), 2.6 parts of silicon nitride (the components of which are below the weight percentage of silicon nitride: 100 mesh ~ 300 46% of target powder and 54% of 300 mesh to 500 mesh powder), 3.9 parts of calcium sulfate whiskers, 75.63 parts of inorganic silicon material (the inorganic silicon material is composed of the following weight percentages: 70~325 mesh quar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com