Preparation method of C-doped TiAlSiN coating

A technology of coating and composite coating, which is applied in the field of preparation of C-doped TiAlSiN coating, can solve problems such as weak anti-adhesion, high internal stress and low internal stress of TiAlSiN coating, so as to improve cutting life and improve Effects of internal structure and surface quality, and excellent cutting life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

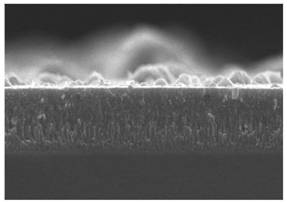

[0023] The embodiment of the present invention discloses a preparation method of C-doped TiAlSiN coating, such as figure 1 shown, including the following steps:

[0024] (1) Put the pretreated substrate into a vacuum chamber and heat it to 450°C for 20 minutes to heat the center and surface of the substrate evenly. The substrate can be high-speed steel;

[0025] (2) Vacuum degree of 0.5Pa, substrate bias voltage -800V, pass through 200sccm Ar, Ti, AlTi and TiSi targets and clean them against the baffles in sequence for 4-8 minutes under 120A current to remove impurities on the target surface;

[0026] (3) The self-cleaning Ti target is connected to a 120A current, 200sccm of Ar is passed through, the vacuum degree is 0.5pa, and the substrate is etched for 6-7min under a bias voltage of -650 to -750V to remove the oxide skin on the surface of the substrate and achieve surface activation. At the same time, a mixed layer is formed between Ti and the substrate, which enhances the...

Embodiment 2

[0039] The embodiment of the present invention discloses a method for preparing a C-doped TiAlSiN coating, comprising the following steps:

[0040] (1) Put the pretreated substrate into a vacuum chamber and heat it to 450°C for 20 minutes to heat the core and surface of the substrate evenly. The substrate can be cemented carbide, such as tungsten-cobalt, tungsten-titanium-cobalt, etc.;

[0041] (2) Vacuum degree of 0.5Pa, substrate bias voltage -800V, pass through 200sccm Ar, Ti, AlTi and TiSi targets and clean them against the baffles in sequence for 4-8 minutes under 120A current to remove impurities on the target surface;

[0042] (3) The self-cleaning Ti target is connected to a 120A current, 200sccm of Ar is passed through, the vacuum degree is 0.5pa, and the substrate is etched for 6-7min under a bias voltage of -650 to -750V to remove the oxide skin on the surface of the substrate and achieve surface activation. At the same time, a mixed layer is formed between Ti and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com