A high-speed EMU axlebox bearing grease composition and preparation method thereof

A grease composition and technology for high-speed EMU, applied in the field of grease, can solve the problems of high transportation cost, expensive imported grease and high use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

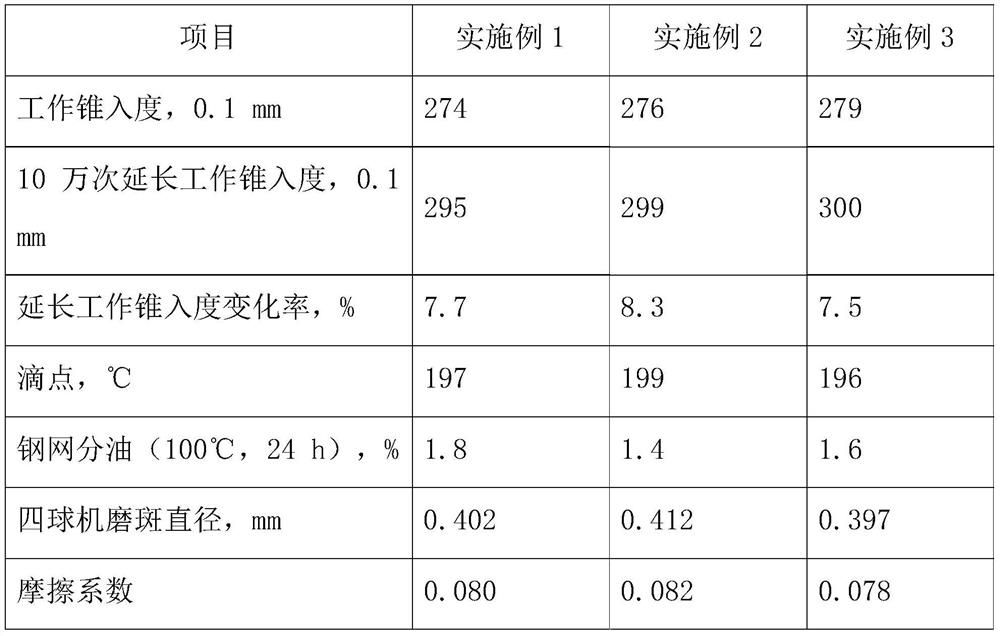

[0020] Embodiments 1-3 Configure each component according to the formula in Table 1.

[0021] Table 1 Embodiment 1-3 formula table

[0022] components Example 1 (%) Example 2 (%) Example 3 (%) 12-Hydroxystearic acid 5.5 6.3 6.1 stearic acid 2.2 1.9 2 Oleic acid 1 1 1 base oil 86.1 84.6 84.3 antioxidant 0.9 0.7 0.8 Chlorinated paraffin 0.6 0.8 0.7 Molybdenum Phosphate 1.2 1.5 1.1 Thiadiazole Derivatives 0.3 0.4 0.5 Molybdenum carbamate 0.7 0.8 1 Melamine cyanurate 1.4 1.8 2.2 modified graphene 0.1 0.2 0.3

[0023] The specific preparation method is to mix type III hydrogenated mineral oil, polyalphaolefin synthetic oil, and ester oil in a weight ratio of 3.5:5.5:1 as a base oil; to mix alkyl diphenylamine and BHT in a weight ratio of 1:1.5, As an antioxidant; add 12-hydroxystearic acid, stearic acid, and oleic acid to base oil with a weight ratio of 10-40%, heat and stir t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com