Method for synthesizing negative electrode material Fe2SSe of lithium-ion battery by one-pot solid-phase method

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as complex synthesis processes, and achieve the effects of high product purity, short synthesis cycle, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

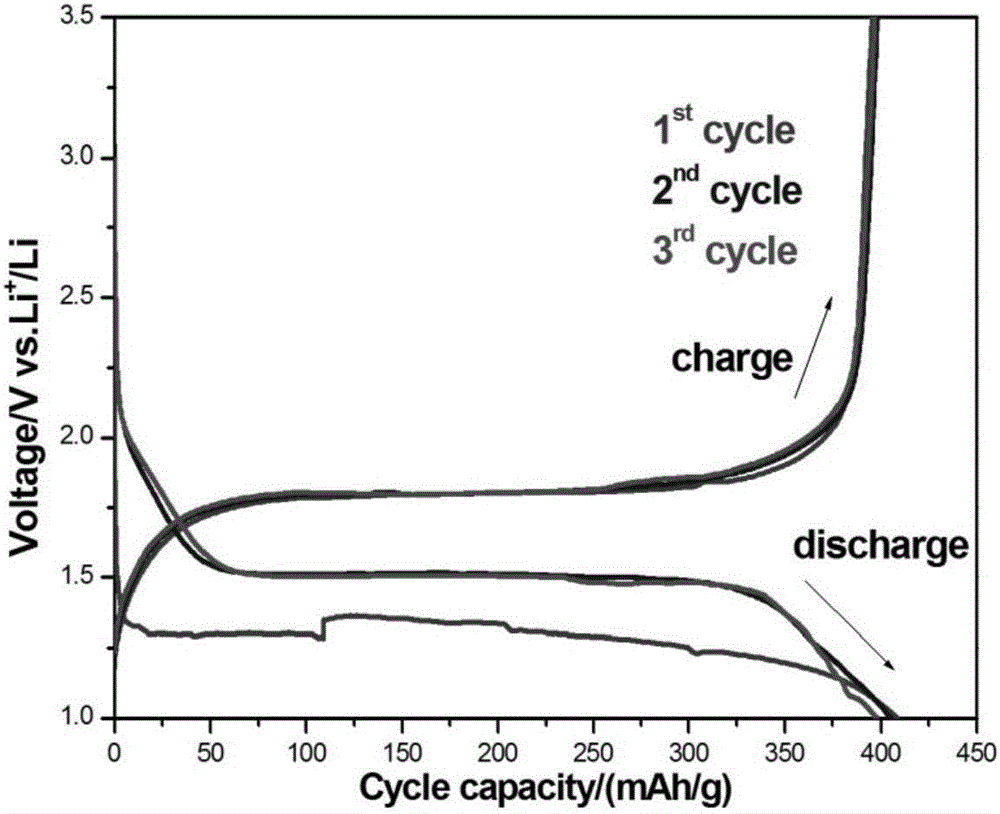

Embodiment 1

[0018] One-pot solid-phase method Fe as an anode material for lithium-ion batteries 2 In the method of Sse, the Fe, Se and S elements with a total mass of 500 mg (the molar ratio of Fe, Se and S are 2:1:1) were weighed and mixed in an agate mortar and ground evenly. Use a tablet press to press the reaction raw materials into tablets, and vacuum-seal the tablets in a quartz tube with an oxyhydrogen flame and a vacuum system, then put the quartz tube into a muffle furnace to heat the reaction, and slowly heat up to 400°C within 10 hours , the heating rate is 40°C / hour, and the temperature is kept for 10 hours; after 10 hours, the temperature is slowly raised to 950°C, the heating rate is 95°C / hour, and the temperature is kept for 30 hours; the muffle furnace is turned off and the temperature is naturally cooled to room temperature to obtain the target product Fe 2 SSe. After the reaction is finished, open the quartz tube to take out the product, grind it for future use.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com