Composite gel polymer electrolyte membrane and application thereof

A technology of electrolyte membrane and composite gel, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of poor mechanical and mechanical strength and heat resistance, improve mechanical and mechanical strength and heat resistance, and improve the interface effect. The effect of strength, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, Comparative Examples 1-2

[0042] 1. Sample preparation

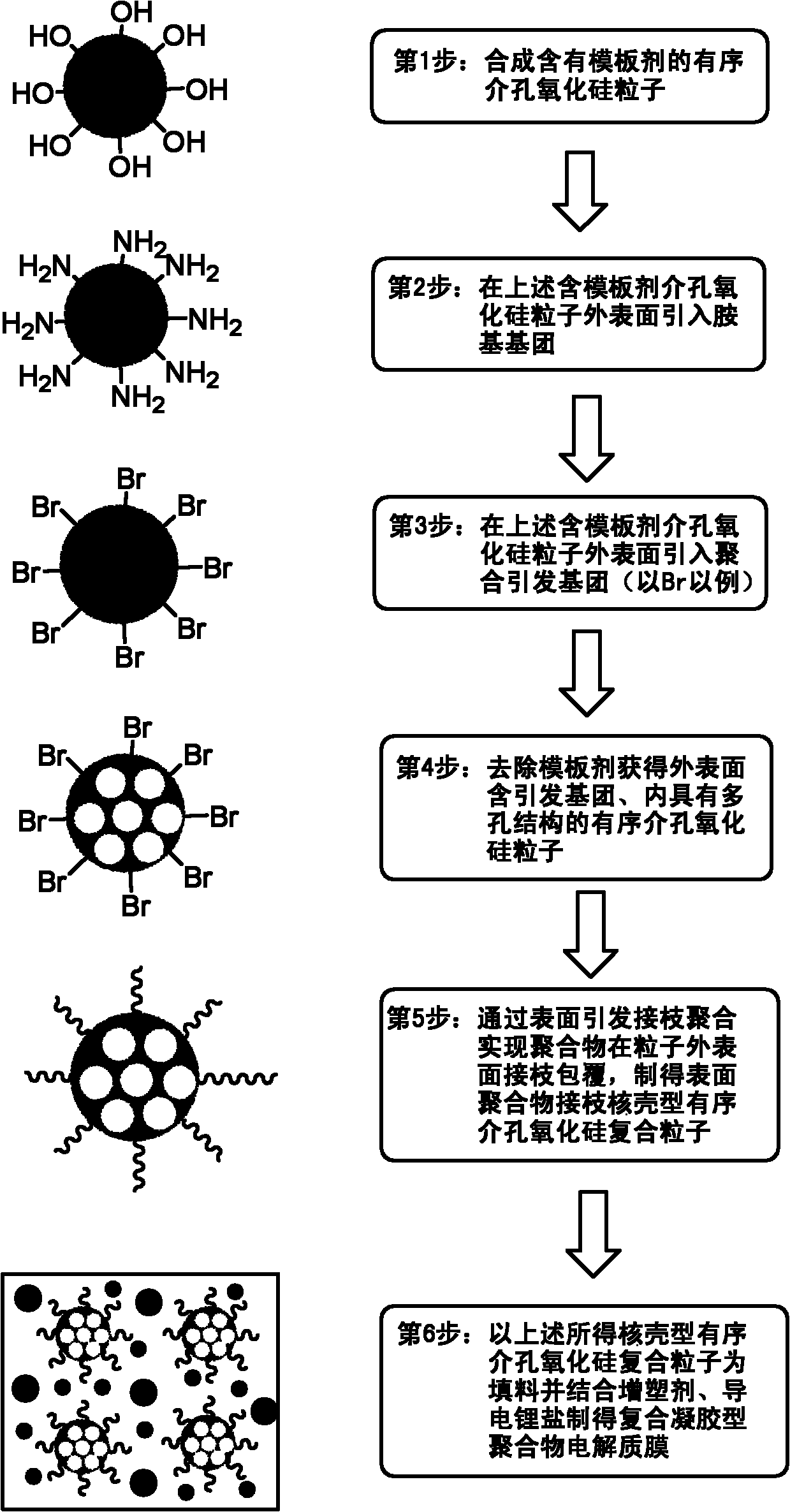

[0043] (1) The preparation of embodiment 1 sample is carried out according to following steps and technology:

[0044] Step 1: Dissolve 1.0 g of cetyltrimethylammonium bromide in 500 mL of distilled water, then add 4 mL of NaOH (2M) into the solution. Gradually raise the temperature to 80° C., drop 20 mL of ethyl orthosilicate into the above solution, and continue to stir and react at constant temperature for 4 h. After the end, the solvent was removed by centrifugation, and the obtained precipitate was repeatedly washed with methanol, and dried in vacuum at 60° C. for 8 hours to obtain white powder A.

[0045] Step 2: Add 4.0g of powder A and 11.5mL of coupling agent γ-aminopropyltriethoxysilane into 600mL of toluene, ultrasonically oscillate for 10min, then gradually raise the temperature to reflux, and continue stirring for 20h. After the reaction, the solvent was removed by centrifugation, an...

Embodiment 2

[0066] Embodiment 2, Comparative Examples 2-3

[0067] 1. Sample preparation

[0068] (1) The preparation of embodiment 2 sample is carried out according to following steps and technology:

[0069] The 1st~5 step technology are with embodiment 1.

[0070] Step 6: Add powder E, plasticizer propylene carbonate, and lithium perchlorate into the polymethyl methacrylate matrix, and prepare a composite gel-type polymer electrolyte membrane through a solution-casting process. The distribution ratio of each component: the mass ratio of the plasticizer to the matrix is 30:100, the mass ratio of the lithium salt to the matrix is 50:100, and the mass ratio of the powder E to the matrix is 10:100. Preparation process: first dissolve the polymer matrix in THF to prepare a uniform polymer solution I (concentration is 40% by mass); then add plasticizer, lithium salt and powder E in THF in proportion, and use ultrasound to It was uniformly dispersed, and the solvent was further remov...

Embodiment 3, comparative example 2、4

[0084] 1. Sample preparation

[0085] (1) The preparation of embodiment 3 sample is carried out according to following steps and technology:

[0086] The 1st~5 step technology are with embodiment 1.

[0087]Step 6: Add powder E, plasticizer propylene carbonate, and lithium perchlorate into the polymethyl methacrylate matrix, and prepare a composite gel-type polymer electrolyte membrane through a solution-casting process. The distribution ratio of each component: the mass ratio of the plasticizer to the matrix is 30:100, the mass ratio of the lithium salt to the matrix is 50:100, and the mass ratio of the powder E to the matrix is 15:100. Preparation process: first dissolve the polymer matrix in THF to prepare a uniform polymer solution I (concentration is 40% by mass); then add plasticizer, lithium salt and powder E in THF in proportion, and use ultrasound to It was uniformly dispersed, and the solvent was further removed by vacuum drying to obtain composite powder II....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com