Resource recycling method for waste lithium batteries

A waste lithium battery, recycling technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of fluoride or electrolyte excessive discharge, to prevent global climate anomalies, facilitate continuous, easy operation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

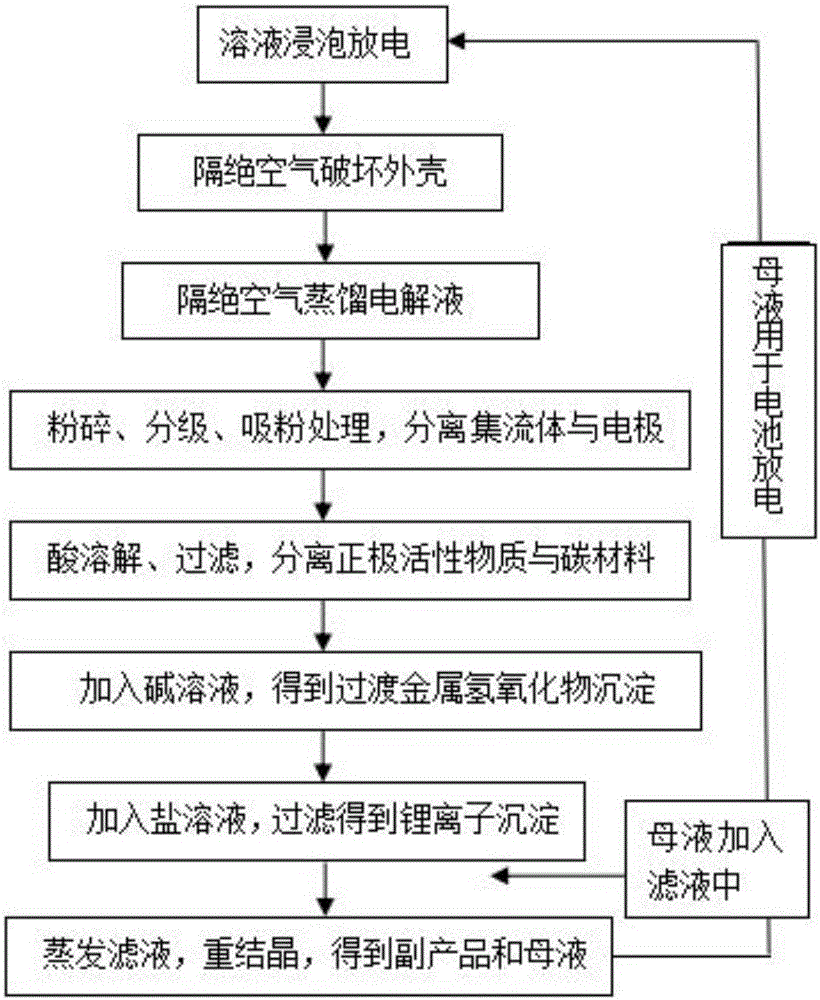

Method used

Image

Examples

Embodiment 1

[0034] Discharge 500kg of plastic-cased mobile phone lithium-ion batteries with an initial rated voltage of 3.7V in an aqueous solution of sodium sulfate to return the voltage to zero. After being fully dried, the plastic case is cut in a glove box under a nitrogen protective atmosphere, and the water vapor content in the glove box is lower than 50ppm. After the treatment is completed, transfer it from the transition chamber to a dry distillation kettle protected by airtight nitrogen, and distill for 90 to 120 minutes at a temperature of 150 to 200 ° C. The distillate flows into the recovery bottle through the condenser for absorption. At the same time, the fluorine-containing waste gas produced is absorbed by the absorption tower with lime water and calcium chloride spray solution and then recovered to ensure that the detection amount of hydrogen fluoride in the tail gas is lower than 10mg / m 3 . For the battery cell removed from the electrolyte taken out of the distillation ...

Embodiment 2

[0036] 1000kg of discarded lithium iron phosphate cylindrical steel case batteries with an initial rated voltage of 3.2V were discharged in an aqueous solution of sodium chloride to return the voltage to zero. After being fully dried, under the protection of argon, in a dry glove box with a water content controlled within 20ppm, use an electric saw to saw the steel shell to expose the inner winding core, and then enter the vacuumized room through an oxygen-free and water-free transition box. In the reaction kettle, under vacuum conditions, the temperature of the reaction kettle is raised to 150-200° C., and the vacuum pump is turned off. The distilled electrolyte vapor is introduced into the collection tank from the condensation pipe, while the non-condensable gas produced by the waste battery core is discharged and fully absorbed by the spray device for treating fluorine-containing waste gas to ensure that the hydrogen fluoride content in the discharged tail gas is lower than ...

Embodiment 3

[0038]Discharge 100kg of steel-cased cylindrical lithium manganese oxide batteries with an initial rated voltage of 3.7V in an aqueous solution of sodium sulfate to return the voltage to zero. After fully drying, dry gloves that control the water content below 30ppm under the protection of argon. In the box, use a chainsaw to saw the steel shell to expose the core package inside, and then enter the argon-protected reactor through the argon-protected transition box, raise the temperature of the reactor to 250-300°C, and the distilled electrolyte steam The condensing pipe is exported into the collection tank, and the non-condensable gas generated by the waste battery core is discharged and fully absorbed by the spray device for treating fluorine-containing waste gas to ensure that the hydrogen fluoride content in the discharged tail gas is lower than 10mg / m3 3 . The core package in the reaction kettle is shelled and removed after cooling the clean electrolyte, and the remaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com