Method for recovering uranium oxide from uranium containing wastewater

A uranium oxide and wastewater technology, applied in chemical instruments and methods, uranium oxides/hydroxides, alkali metal oxides/hydroxides, etc., can solve the problems of low efficiency, difficult industrialization, restrictions, etc., and achieve convenient recovery , The effect of simple process flow and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

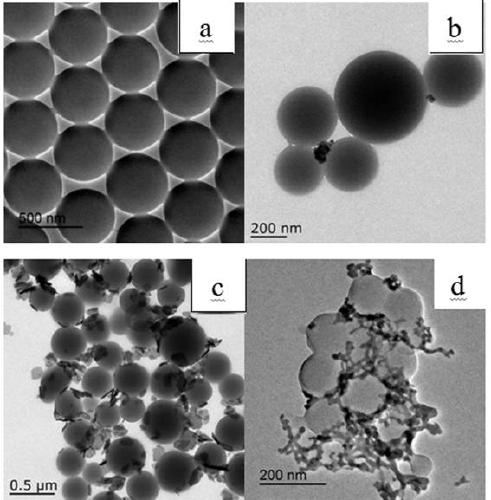

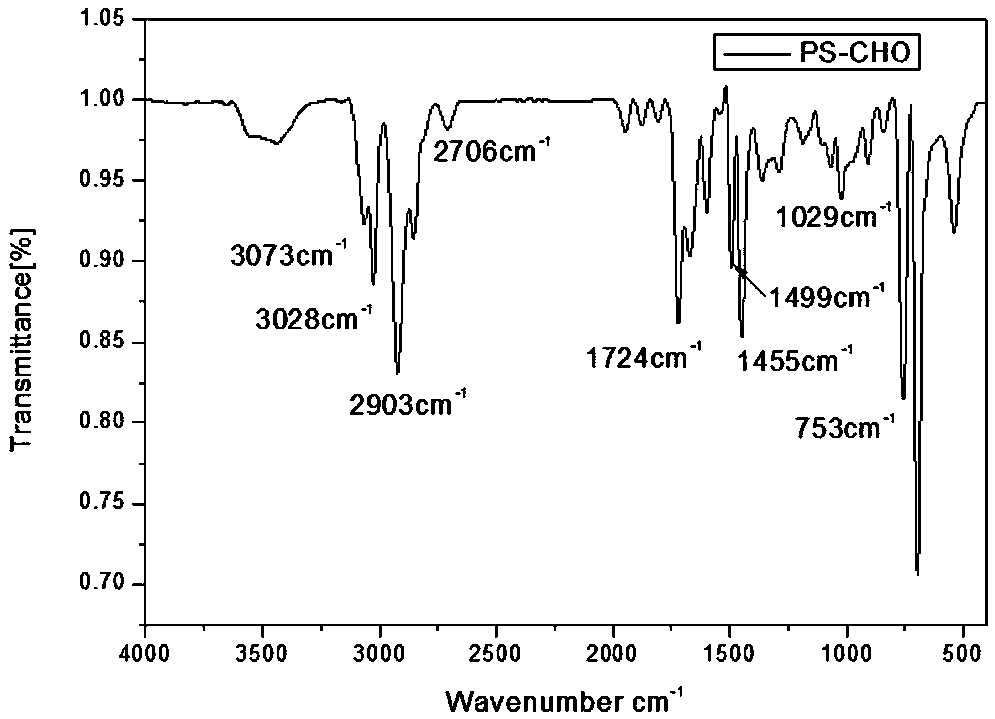

[0030] First prepare polystyrene aldehyde-based microspheres:

[0031] (1) Mix 18 mL of isopropanol and 2.5 g of polyvinylpyrrolidone PVP dispersant, ultrasonically assist in dissolving, add to a three-neck flask equipped with a condenser, and place it in a constant temperature water bath at 70°C, mechanically stir and keep the speed is 315 r / min;

[0032] (2) Dissolve 0.1g of azobisisobutyronitrile AIBN initiator in 6mL of styrene to prepare a styrene solution in which the initiator is dissolved;

[0033] (3) Add the styrene solution in which the initiator is dissolved in (2) to the system obtained in (1), stir to make it fully mixed for 30 minutes, then add 3 mL of acrolein C 3 h 4 O, react at a constant temperature at 70 °C for 8 h, stop the reaction, and wash with ethanol and water for three times by ultrasonic centrifugation to prepare polystyrene aldehyde-based spherical emulsion, and obtain polystyrene aldehyde-based microspheres after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com