A kind of aluminum alloy surface activated connection method

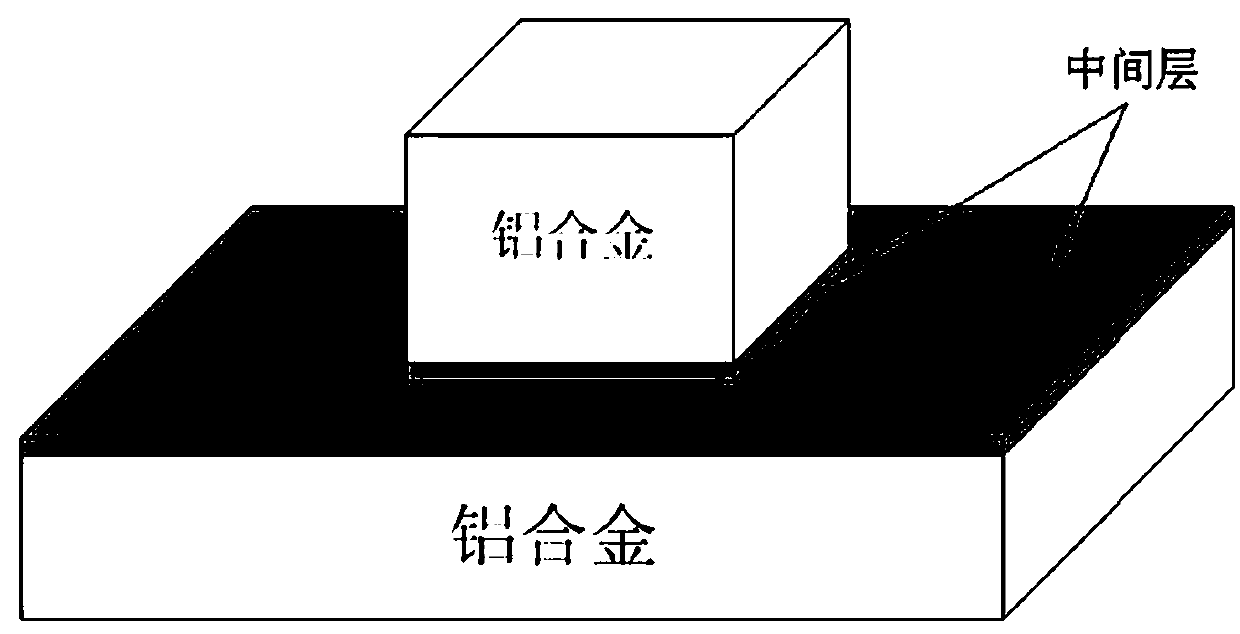

A technology of aluminum alloy surface and connection method, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of high pressure and vacuum, reduce the performance of brazed joints, and take a long time to achieve The middle layer is dense, the adverse effects are eliminated, and the performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The steps of an aluminum alloy surface activated connection method are as follows:

[0026] 1) Grind two pieces of 1060 aluminum alloys with dimensions of 10mm×20mm×5mm and 5mm×5mm×5mm in turn with 600#, 800#, 1200#, 1500#, 2000# metallographic sandpaper, and then use 10% NaOH Solution, 10%HNO 3 The solution was chemically cleaned for 10-15s, then rinsed with deionized water, and finally cleaned with absolute ethanol and acetone for 15 minutes with ultrasonic waves and dried;

[0027] 2) Put the 1060 aluminum alloy sample into the magnetron sputtering equipment, and draw the vacuum to 5×10 -3 After Pa, pure Ar (purity 99.99%) was introduced, and the pure Si target was pre-sputtered for 10 minutes. Before the Si film was deposited by magnetron sputtering, a negative high voltage was provided to the substrate through a pulse bias power supply, and the self-luminescence of the substrate surface was utilized. Plasma generated by photodischarge cleans the surface of the s...

Embodiment 2

[0031] The steps of an aluminum alloy surface activated connection method are as follows:

[0032] 1) Grind two pieces of 7075 aluminum alloys with dimensions of 10mm×20mm×5mm and 5mm×5mm×5mm in turn with 600#, 800#, 1200#, 1500#, 2000# metallographic sandpaper, and then use 10% NaOH Solution, 10%HNO 3 The solution was chemically cleaned for 10-15s, then rinsed with deionized water, and finally cleaned with absolute ethanol and acetone for 15 minutes with ultrasonic waves and dried;

[0033] 2) Put the 7075 aluminum alloy sample into the magnetron sputtering equipment, and draw the vacuum to 5×10 -3 After Pa, pure Ar (purity 99.99%) was introduced, and the pure Cu target was pre-sputtered for 10 minutes. Before the Cu film was deposited by magnetron sputtering, a negative high voltage was provided to the substrate through a pulse bias power supply, and the self-luminescence of the substrate surface was utilized. Plasma generated by photodischarge cleans the surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com