Preparation method of high-rate copper-doped lithium titanate negative electrode material

A technology of heterolithic lithium titanate and negative electrode materials, which is applied in the field of copper-doped lithium titanate negative electrode materials, can solve the problems of complex preparation methods, unstable samples, and inability to change the internal structure of electrodes, and achieve low calcination temperature and short time , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

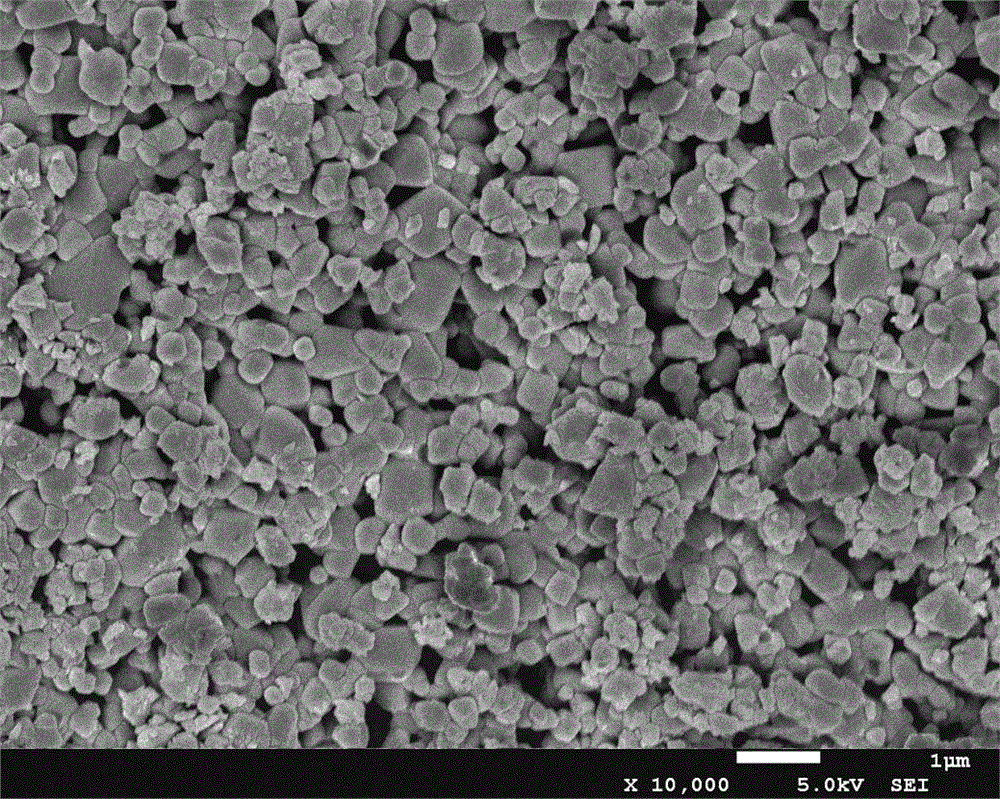

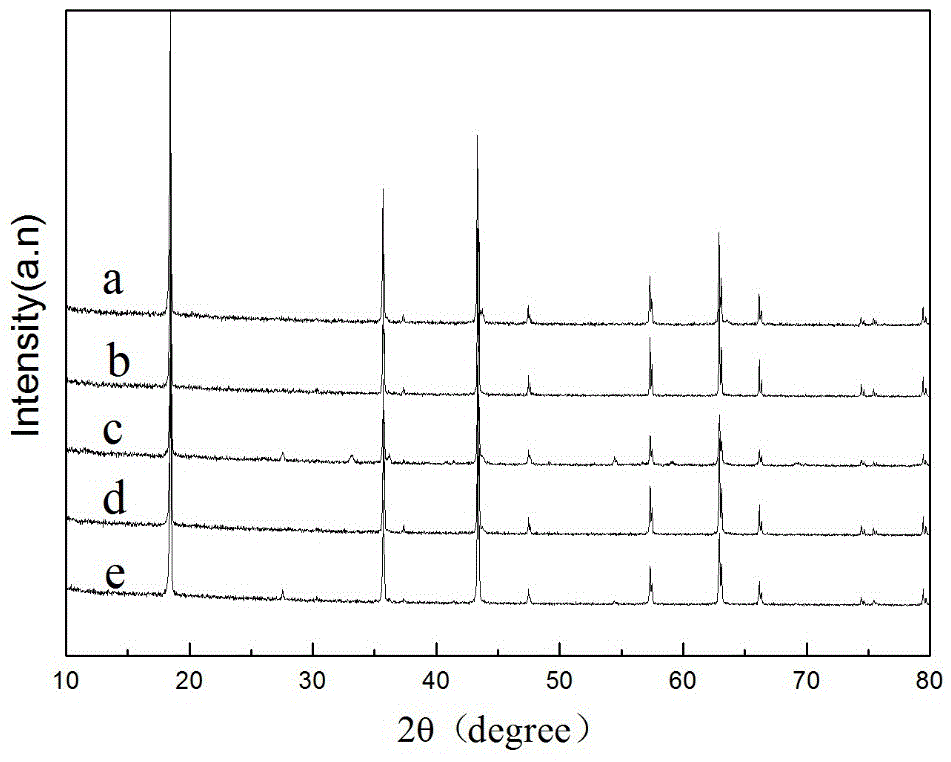

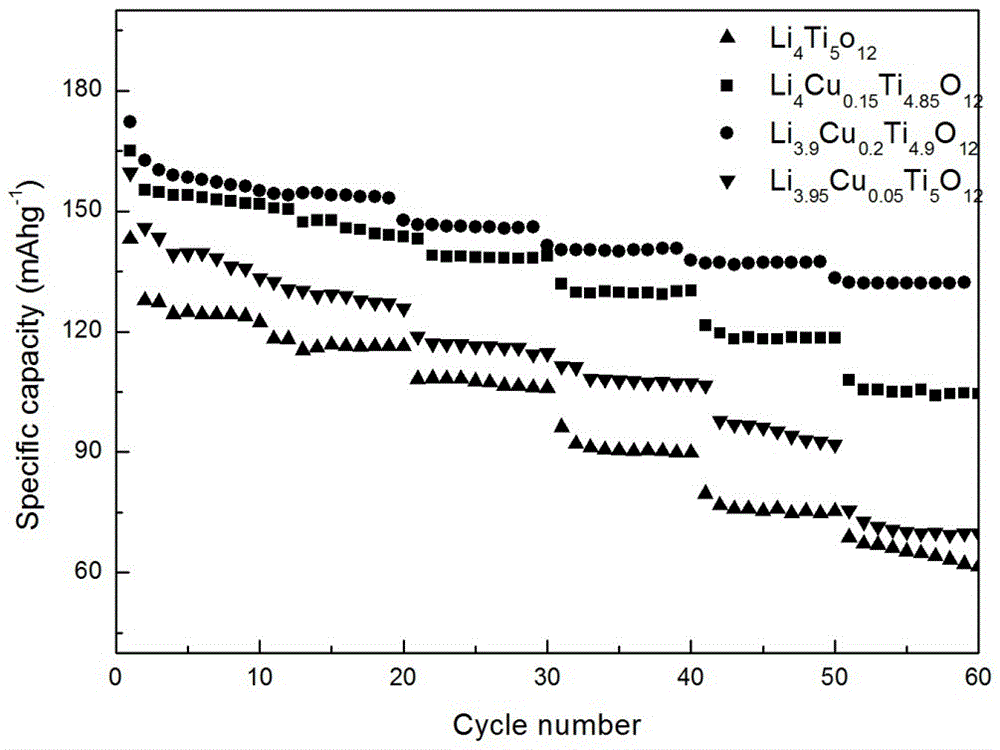

[0021] x=0.05, y=0 molecular formula is: Li 3.95 Ti 5 Cu 0.05 o 12 , its preparation process is:

[0022] Weigh 2.08g of lithium acetate into a flask containing 30ml of ethanol, add 13.06g of butyl titanate, 0.096g of copper sulfate pentahydrate, and 1.85g of anhydrous oxalic acid in sequence, and stir for 6 hours to form a blue transparent sol, then let it stand for 24 hours Gel is formed, after grinding, it is pre-calcined in a muffle furnace at 500°C for 2 hours, then calcined at 800°C for 10 hours, cooled to room temperature, and ground to obtain a copper-doped lithium titanate product.

Embodiment 2

[0024] x=0.1, y=0.1, the molecular formula is: Li 3.9 Ti 4.9 Cu 0.2 o 12 , its preparation process is:

[0025] Weigh 2.17g of lithium nitrate and place it into a flask containing 30ml of ethanol, add 12.96g of butyl titanate, 0.38g of copper nitrate trihydrate, and 1.65g of anhydrous oxalic acid in sequence, and stir for 6 hours to form a blue transparent sol, then let it stand for 24 hours Gel is formed, after grinding, it is pre-calcined in a muffle furnace at 500°C for 2 hours, then calcined at 800°C for 10 hours, cooled to room temperature, and ground to obtain a copper-doped lithium titanate product.

Embodiment 3

[0027] x=0., y=0.15, the molecular formula is: Li 4 Ti 5 Cu 0.1 5O 12 , its preparation process is:

[0028] Weigh 2.33g of lithium carbonate and place it into a flask containing 30ml of ethanol, add 12.51g of butyl titanate, 0.275g of copper nitrate trihydrate, and 0.52g of CTAB in sequence, and stir for 6 hours to form a blue transparent sol, then let it stand for 24 hours to form a gel After grinding, place it in a muffle furnace for pre-calcination at 500°C for 2h, then calcinate in a reducing atmosphere at 800°C for 10h, cool to room temperature, and grind to obtain the copper-doped lithium titanate product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com