A kind of high-purity rare earth metal and its preparation method and application

A rare earth metal, high-purity technology, applied in the field of high-quality metal material manufacturing, can solve the problems of serious oxidation of rare earth metals and high oxygen content, reduce the generation of large non-metallic inclusions, prevent the increase of impurity elements, and ensure stable and smooth production. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1——Preparation of high-purity rare earth

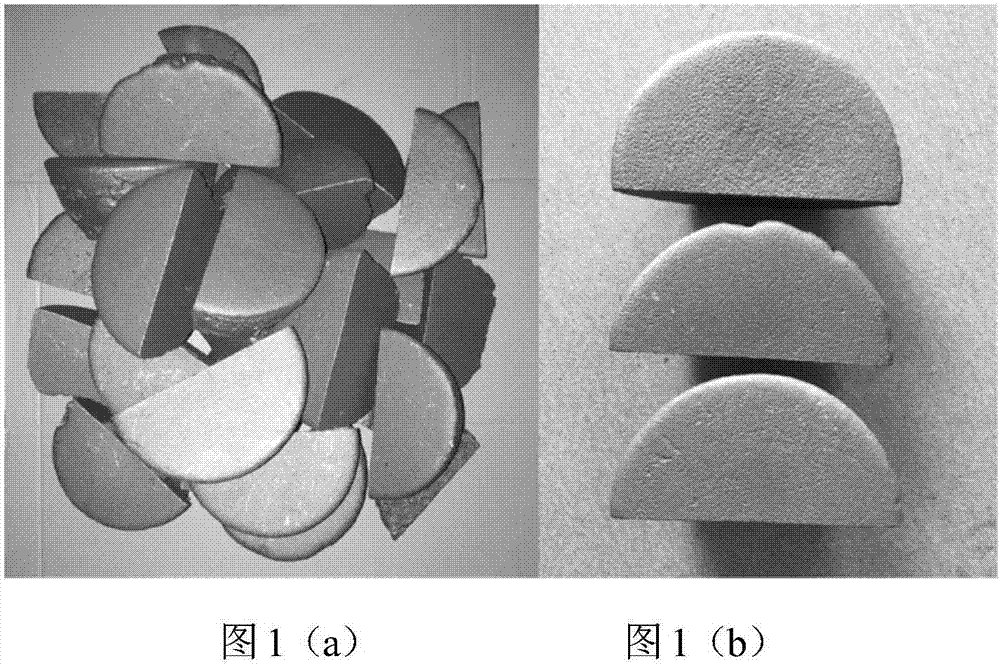

[0037] In this embodiment, rare earth oxides (lanthanum oxide and cerium oxide) are used as raw materials, and electrolysis is carried out in a graphite electrolytic cell with an electrolysis voltage of 120V, a current of 800A, and an electrolysis time of 2 hours, to reduce the rare earth metals to a molten state at 900°C. After the electrolysis process, the molten rare earth metal is solidified under the cover of chloride salt (such as: KCl), and the rare earth metal obtained is as follows: Figure 1(a)-Figure 1(b) shown.

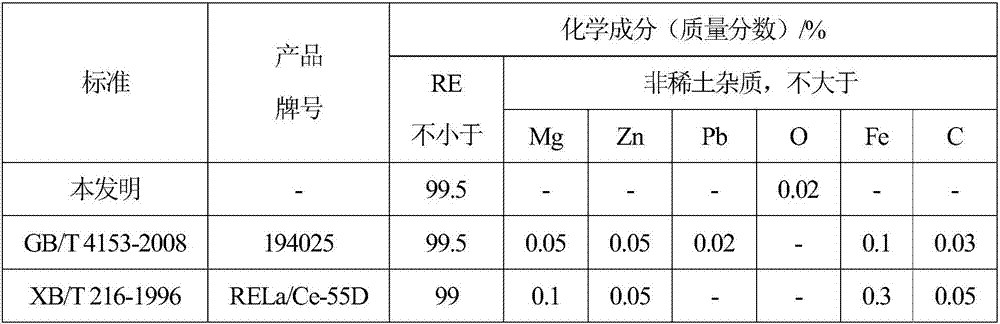

[0038] After analysis and detection, the contents of rare earth elements and main impurity elements are shown in Table 1.

[0039] Table 1 The main components of the high-purity rare earth metals prepared by the embodiments of the present invention (the balance is other impurity elements)

[0040] element

Embodiment 2

[0049] Example 2——Preparation of high-purity rare earth

[0050] In this example, rare earth oxide fluoride salts (lanthanum oxyfluoride and cerium oxyfluoride) were used as raw materials, and electrolysis was carried out in a graphite electrolytic cell with an electrolysis voltage of 150V, a current of 850A, and an electrolysis time of 3 hours to reduce the rare earth metal to a molten state at 1000°C. After the electrolysis process, the molten rare earth metal is solidified under the cover of fluorine salt (such as: LiF).

[0051] After analysis and detection, its rare earth element content and main impurity element content are shown in Table 4.

[0052] Table 4 The main components of the high-purity rare earth metals prepared by the embodiments of the present invention (the balance is other impurity elements)

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com