Low-smoke halogen-free flame-retardant crack-resistant cable material and preparation method thereof

A technology of anti-cracking and cable materials, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of easy cracking of low-smoke, halogen-free flame-retardant cable sheaths, etc., to improve environmental stress cracking resistance, improve flame-retardant performance, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A low-smoke, halogen-free, flame-retardant and anti-cracking cable material, which is prepared from the following raw materials in parts by weight (kg): high-density polyethylene 65, ethylene-vinyl acetate copolymer 30, alkyl phenyl sulfonate 7, diethanolamine Borate 4, Magnesium Dimethacrylate 3, Magnesium Hydroxide 8, Cresyl Diphenyl Phosphate 40, 3-Aminopropyltriethoxysilane 4, Trimethylsilyl Cage Polysilsesquioxane Alkane 7, organic antimony stabilizer 6, p-phenylenediamine 5, nano colemanite 30, omega mineral fiber 8, hexachlorocyclotriphosphazene 8, carnauba wax 6, polyarylether ether nitrile 10, zirconium carbide 7. Hemp knife ash 5. Calcium hypophosphite 4. High wear-resistant carbon black 8.

[0016] A method for preparing a low-smoke, halogen-free, flame-retardant and anti-cracking cable material, comprising the following steps:

[0017] (1) Magnesium hydroxide, 3-aminopropyltriethoxysilane, trimethylsilyl clathrate polysilsesquioxane, organic antimony stabil...

Embodiment 2

[0021] A low-smoke, halogen-free, flame-retardant and anti-cracking cable material, which is prepared from the following raw materials in parts by weight (kg): high-density polyethylene 70, ethylene-vinyl acetate copolymer 35, alkyl phenyl sulfonate 8, diethanolamine Borate 5, Magnesium Dimethacrylate 4, Magnesium Hydroxide 9, Cresyl Diphenyl Phosphate 45, 3-Aminopropyltriethoxysilane 5.5, Trimethylsilyl Cage Polysilsesquioxane Alkane 8, organic antimony stabilizer 7, p-phenylenediamine 6, nano colemanite 35, Omega mineral fiber 9, hexachlorocyclotriphosphazene 9, carnauba wax 7, polyarylether ether nitrile 11, zirconium carbide 7.5, hemp knife ash 6.5, calcium hypophosphite 5, high wear-resistant carbon black 10.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] A low-smoke, halogen-free, flame-retardant and anti-cracking cable material, which is prepared from the following raw materials in parts by weight (kg): high-density polyethylene 75, ethylene-vinyl acetate copolymer 40, alkyl sulfonate phenyl ester, diethanolamine boron Ester 6, Magnesium Dimethacrylate 5, Magnesium Hydroxide 10, Cresyl Diphenyl Phosphate 50, 3-Aminopropyltriethoxysilane 7, Trimethylsilyl Cage Polysilsesquioxane 9. Organic antimony stabilizer 8, p-phenylenediamine 7, nano colemanite 40, omega mineral fiber 10, hexachlorocyclotriphosphazene 10, carnauba wax, polyarylether ether nitrile 12, zirconium carbide 8, Hemp knife ash 8, calcium hypophosphite 6, high wear-resistant carbon black 12.

[0025] The preparation method is the same as in Example 1.

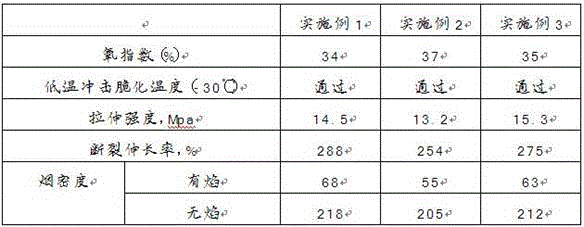

[0026] The performance detection result of the cable material that above-mentioned embodiment 1-3 makes is shown in the table below:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com