Method for efficiently collecting platinum group metals through mixing reduction smelting of iron powder and iron ores

A technology for platinum group metals and iron powder, which is applied in the field of mixed reduction and smelting of iron powder and iron ore to efficiently capture platinum group metals, and achieves the effects of easy industrialization, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

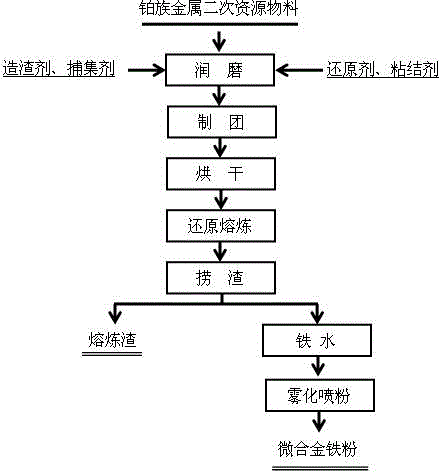

[0034] See attached figure 1 , Conditions: 1000g of platinum group metal secondary resource material, the amount of collector iron powder and iron ore is 40% by weight of platinum group metal secondary resource material (wherein iron powder: magnetite concentrate = 2:1, reduction The amount of anthracite as an agent is 4% of the weight ratio of platinum group metal secondary resource materials, the amount of binder coal tar is 0.4% of the weight ratio of platinum group metal secondary resource materials, and the amount of slagging agent is 0.4% of the weight ratio of platinum group metal secondary resource materials. 30% of the material weight ratio (lime: quartz powder: fluorite = 4:4:2), mix evenly, use a pelletizing machine to make 5cm pellets, dry to obtain composite pellets; put them into the induction furnace in batches Add composite pellets, mix and smelt, the smelting temperature is 1350°C, and the smelting time is 2h. After smelting for a period of time, remove the sm...

Embodiment 2

[0036] See attached figure 1 , conditions: 2000g of platinum group metal secondary resource material, the amount of collector iron powder and iron ore is 30% by weight of platinum group metal secondary resource material (wherein iron powder: limonite concentrate = 3:1, reduction The amount of anthracite as an agent is 3% of the weight ratio of platinum group metal secondary resource materials, the amount of binder coal tar is 0.4% of the weight ratio of platinum group metal secondary resource materials, and the amount of slagging agent is 0.4% of the weight ratio of platinum group metal secondary resource materials. 30% of the material weight ratio (lime: quartz powder: fluorite = 4:5:1), mix well, use a pelletizing machine to make 5cm pellets, dry to obtain composite pellets; put them into the induction furnace in batches Add composite pellets, mix and smelt, the smelting temperature is 1450°C, and the smelting time is 2h. After smelting for a period of time, remove the smelt...

Embodiment 3

[0038] See attached figure 1 , condition: 2000g of platinum group metal secondary resource material, the amount of collector iron powder and iron ore is 30% by weight of platinum group metal secondary resource material (wherein iron powder: siderite concentrate = 4:1, reduction The amount of anthracite as an agent is 3% of the weight ratio of platinum group metal secondary resource materials, the amount of binder coal tar is 0.4% of the weight ratio of platinum group metal secondary resource materials, and the amount of slagging agent is 0.4% of the weight ratio of platinum group metal secondary resource materials. 30% of the material weight ratio (lime: quartz powder: fluorite = 5:4:1), mix well, use a pelletizer to make 5cm pellets, dry to obtain composite pellets; put them into induction furnace in batches Add composite pellets, mix and smelt, the smelting temperature is 1350°C, and the smelting time is 2h. After smelting for a period of time, remove the smelting slag, pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com