Continuous hot galvanizing method for 1180 MPa-grade Q&P steel

A technology of hot-dip galvanizing and heating section, applied in hot-dip plating process, heat treatment furnace, heat treatment equipment and other directions, can solve the problems of dezincification, difficult to guarantee coating adhesion, external oxidation, etc., to achieve good adhesion, improve Excellent adhesion and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

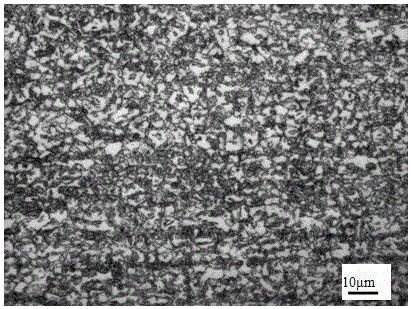

Image

Examples

Embodiment Construction

[0018] The continuous hot-dip galvanizing method of this 1180MPa grade Q&P steel is produced by the following process steps:

[0019] (1) The chilled coil of Q&P steel is used for continuous hot-dip galvanizing. The production process of the chilled coil is: smelting-continuous casting-hot rolling-acid rolling.

[0020] A. Molten steel is made into continuous casting slab through converter, LF furnace, continuous casting and other processes. The mass percentage of the chemical composition of the continuous casting slab is: C 0.15-0.25%, Si 0.3-2.0%, Mn 1.0-5.0%, S≤0.01%, P≤0.01%, H≤20ppm, Al 0.02-2.0%, Nb 0.01 ~ 0.04%, the rest is Fe and unavoidable impurities.

[0021] B. The hot rolling: including heating, rough rolling, finish rolling, laminar cooling and coiling, to make hot rolled coils with a thickness of 3-5mm. Among them, the heating temperature is 1180°C, and the heat preservation is 1.5 hours; the total reduction of finishing rolling is ≥60%, the starting temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com