Method for improving mechanical surface strengthening effect

A technology of mechanical strengthening and surface structure, applied in the field of metal strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

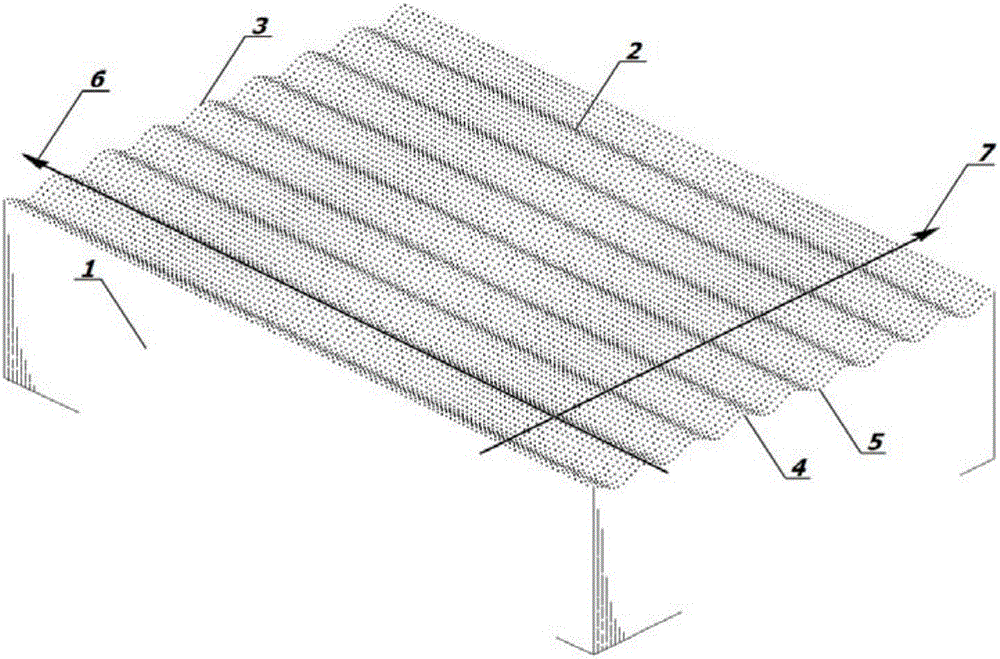

Embodiment 1

[0057] Using compressed air or centrifugal sand blasting device, according to the hardness of the material to be strengthened and the peak-to-valley depth difference 14 of the surface structure to be prepared, select abrasives such as angular steel grit, corundum or silicon carbide, and determine the sand blasting process parameters. Carry out degreasing and deembroidery treatment on parts or structures to be treated, and shield and protect non-treated parts of parts or structures with materials such as tapes and adhesive plasters. During sandblasting, the axis of the sandblasting gun should be at an angle of 60° to 80° with the surface of the part to ensure uniform sandblasting coverage and avoid overspraying to ensure a uniform prefabricated surface structure. After sandblasting, use compressed air to dedust and remove the pretreated surface to avoid abrasive particles remaining in the surface structure. After the surface structure prefabrication is completed, the surface me...

Embodiment 2

[0060] When machining the prefabricated surface structure by turning, milling or grinding, it can be carried out on ordinary machine tools or CNC machine tools. First, select or customize the appropriate tool according to the material of the part to be strengthened, and determine the feed rate according to the peak-to-valley depth difference 14 and wavelength 15 of the surface structure to be prepared. If the surface to be treated is dirty, it should be degreased and deembroidered first. After the surface structure prefabrication is completed, the surface mechanical strengthening treatment is carried out in the shortest possible time to prevent oxidation or corrosion.

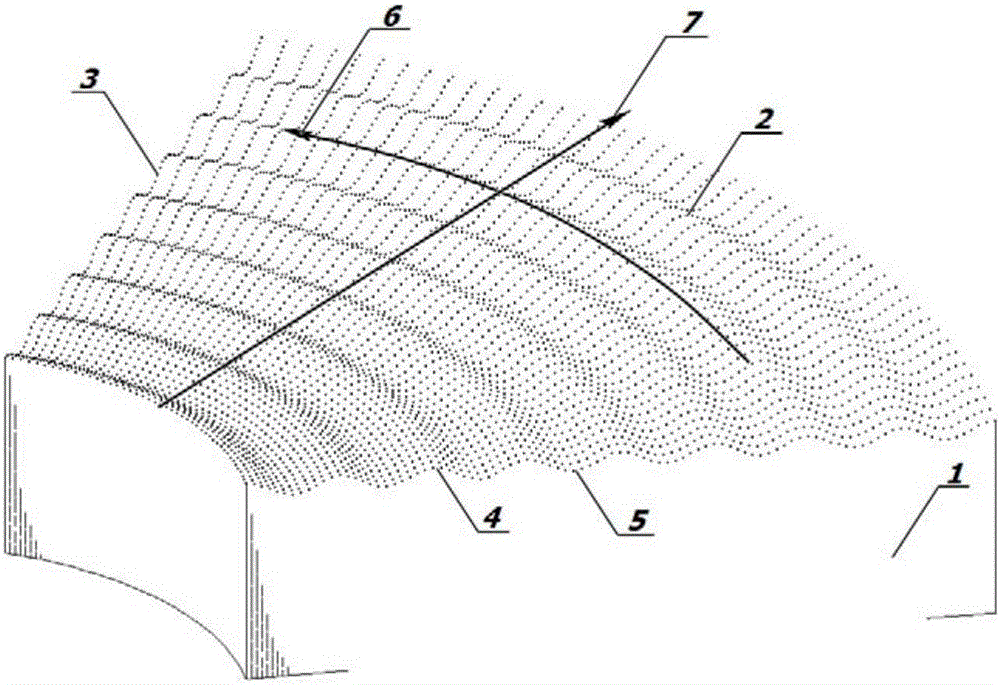

[0061] For anti-fatigue strengthening treatment, when using machining methods to prefabricate the surface structure of parallel straight corrugations or parallel curved corrugations, attention should be paid to making the longitudinal direction of the surface structure 7 consistent with the working principal st...

Embodiment 3

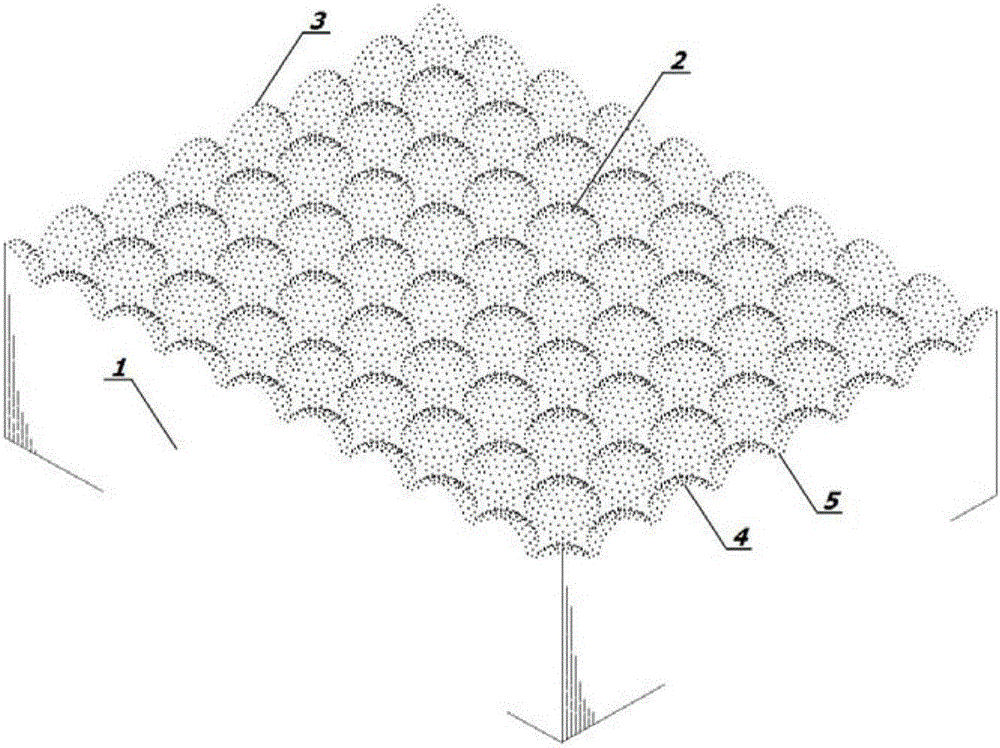

[0063] For the prefabricated surface structure of the hole wall of the inner hole part or the irregular local concave-convex part of the part, an electric wire brush can be used to realize it. First, select a steel wire brush (wheel) with appropriate hardness according to the material of the part to be strengthened, and the diameter of the steel wire is determined according to the peak-to-valley depth difference 14 and wavelength 15 of the surface structure to be prepared. During operation, care should be taken to ensure the uniformity of the prefabricated surface structure.

[0064] This method can prefabricate the surface structure of parallel straight corrugations and parallel curved corrugations, and can also prefabricate isotropic surface micro-scratch or surface asperity surface structure. When prefabricating a directional surface structure, attention should be paid to make the longitudinal direction 7 of the surface structure consistent with the working principal stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com