Rear surface passivation contact battery electrode structure and preparation method thereof

A technology of back passivation and battery electrodes, which is applied in the field of solar cells, can solve the problems of expensive metal electrodes, the inability to take advantage of the potential advantages of N-type batteries, and the reduction of battery costs, achieving high pass rate, reduced shading area, and production methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

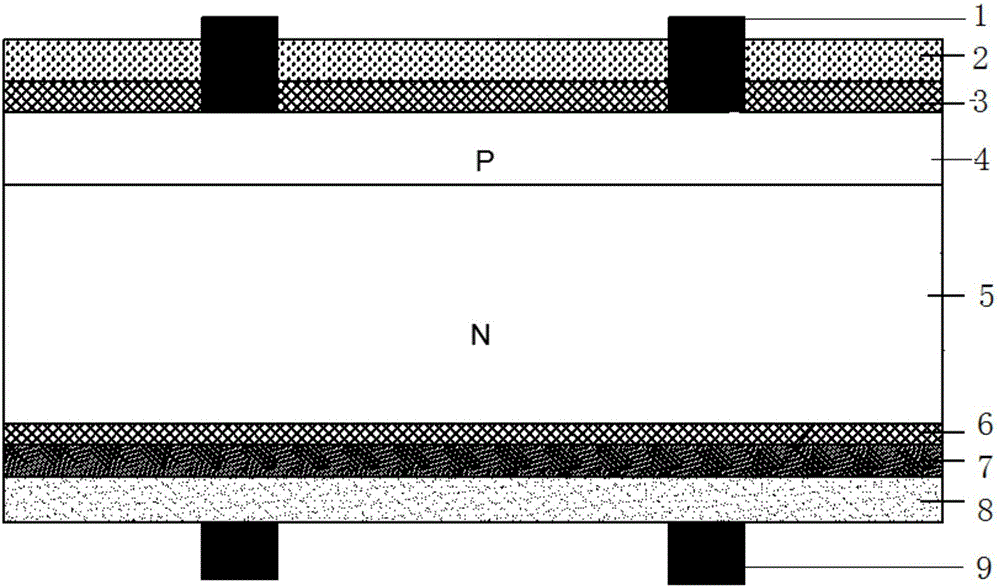

[0031] The preparation method of the above-mentioned backside passivation contact battery backside structure comprises the following steps:

[0032] 1) The N-type crystalline silicon wafer is processed by texturing, diffusion, etching, passivation film and anti-reflection film on the front side, and then the back electrode of the battery is made according to the following steps.

[0033] 2) Fabricate a tunneling silicon oxide film 6 on the back of the N-type crystalline silicon wafer with a film thickness of 1-2nm. The fabrication methods can be LPCVD, PECVD, ALD, thermal oxidation, ozone oxidation, wet chemistry, electrochemical, anodic oxidation, etc. .

[0034] 3) An N-type doped crystal silicon layer 7 is fabricated on the tunneling silicon oxide, and the thickness of this layer is 10-1000 nm. Manufacturing method: ①Using LPCVD and vapor phase epitaxy to directly form N-type doped crystalline silicon layer 7; ②Using PECVD method to first form N-type doped amorphous silico...

Embodiment 1

[0042] (1) N-type crystalline silicon wafers are processed by texturing, diffusion, etching, passivation film and anti-reflection film on the front side, and then the back electrode is made according to the following steps.

[0043] (2) Fabricate a tunneling silicon oxide layer with a thickness of 2nm on the back side by LPCVD.

[0044] (3) An N-type doped microcrystalline silicon layer with a thickness of 30 nm is fabricated on the tunneling silicon oxide layer by LPCVD.

[0045] (4) Sputtering is used to fabricate an ITO transparent conductive film with a thickness of 100 nm on the N-type doped microcrystalline silicon layer.

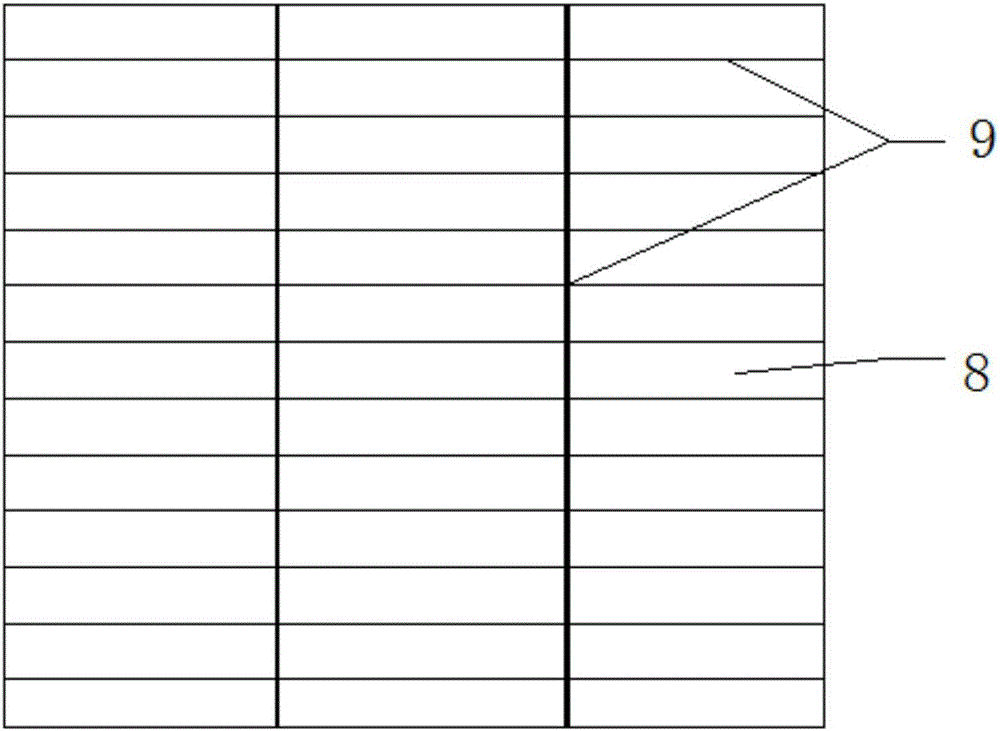

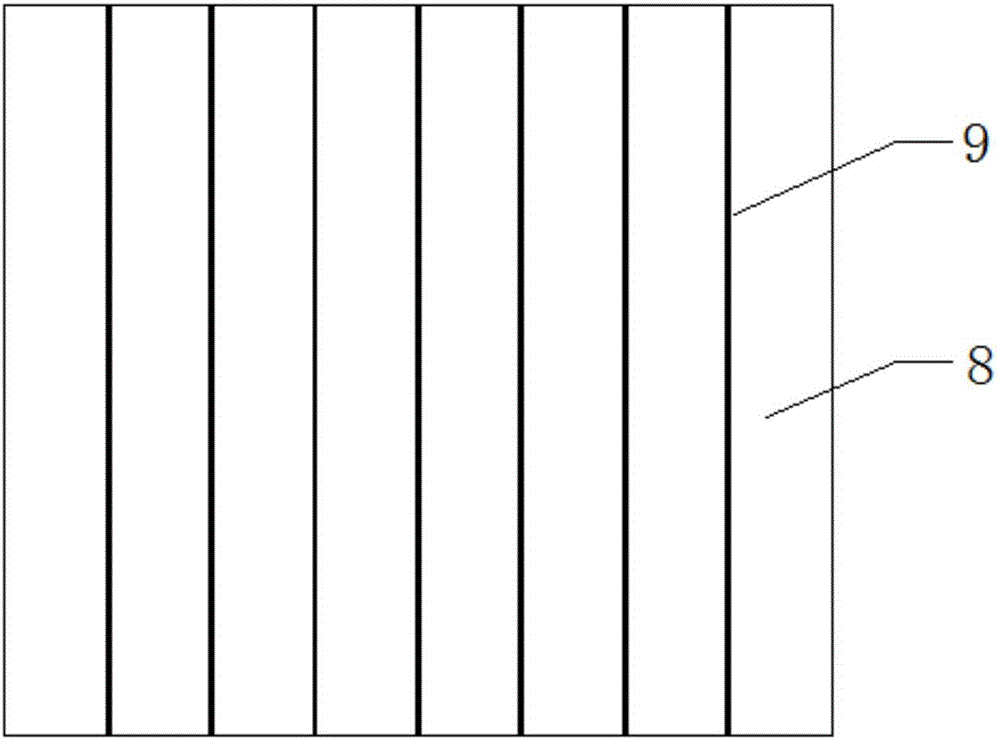

[0046] (5) Fabricate silver electrodes on the transparent conductive film by inkjet method, followed by heat treatment. The silver electrode is composed of a group of equally spaced and parallel thin grid lines and a group of equally spaced parallel main grid lines, and the thin grid lines and the main grid lines are vertically intersected. There ar...

Embodiment 2

[0049] (1) N-type crystalline silicon wafers are processed by texturing, diffusion, etching, passivation film and anti-reflection film on the front side, and then the back electrode is made according to the following steps.

[0050] (2) Fabricate a tunnel silicon oxide film with a thickness of 1 nm on the back side by PECVD.

[0051] (3) An N-type doped amorphous silicon layer with a thickness of 50 nm is fabricated on the tunneling silicon oxide film by PECVD.

[0052] (4) Perform annealing at 200-500°C under a protective atmosphere to convert doped amorphous silicon into microcrystalline silicon;

[0053] (5) AZO transparent conductive film with a thickness of 150 nm was fabricated on the N-type doped microcrystalline silicon layer by sputtering.

[0054] (6) A silver electrode is fabricated on the transparent conductive film by screen printing, followed by heat treatment. The silver electrode is composed of 10 sets of grid lines parallel to each other at equal intervals, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com