A kind of preparation method of diamond-cubic boron nitride-boron carbide composite material

A technology of cubic boron nitride and composite materials, which is applied in the field of superhard material manufacturing for cutting tools, can solve the problems of poor metal stability, poor oxidation resistance, and restrictions on practical application, and achieve high stability, uniform and dense structure, and high The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The composite material preparation method comprises the following steps:

[0019] ①. Select diamond, cubic boron nitride, and boron carbide powder as raw materials; diamond, cubic boron nitride, and boron carbide powder are required to be purified to remove impurities, with an average particle size of 20 nm-20 μm, and the weight of diamond powder is 10-80 parts. The weight part of cubic boron nitride powder is 20-80 parts, and the weight part of boron carbide powder is 5-20 parts. It also includes a binder material, the binder powder is a compound or a simple substance according to the actual processing object, one or more of Co, Ti, Al, Si, SiC, the particle size is 20 nm-20 μm, and the sticky The weight part of the binder powder is 0-50 parts.

[0020] ②. Evenly mix the mixed powder selected in the above ① and put it into a molybdenum cup for packaging;

[0021] ③. The molybdenum cup assembled in ② is pre-pressed, vacuum pre-fired, pyrophyllite composite block cavit...

Embodiment 1

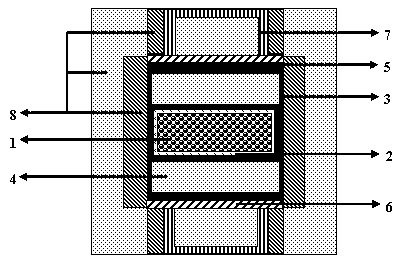

[0023] as attached figure 1 Shown: select diamond powder with a particle size of 0.5 μm, cBN powder with a particle size of 0.25 μm, and B with a particle size of 3 μm 4 C, Si powder of 1 μm is used as raw and auxiliary materials, and the parts by weight are: 15 parts, 70 parts, 10 parts, and 5 parts. Mix the powder for 2 hours until it is uniform, put 1g of the mixed powder 1 into a molybdenum cup 2 with an inner diameter of 14.8mm after being pre-pressed at 5MPa, perform a vacuum heat treatment at 500°C for 0.5h, then put it into a heated graphite tube 3, and finally assemble Component insulation sheet 4, thermal insulation graphite sheet 5, conductive metal sheet 6, and conductive steel cap 7 are put into the pyrophyllite composite block 8. The size of the pyrophyllite composite block is 32.5mm×32.5mm×32.5mm, and the diameter of the synthetic cavity is 18mm. The graphite tube 7 has an inner diameter of 16mm and a height of 17mm. The six-sided top press (CS- , 6×14000 KN...

Embodiment 2

[0025] as attached figure 1 Shown: select diamond powder with a particle size of 0.5 μm, cBN powder with a particle size of 0.25 μm, and B with a particle size of 3 μm 4 C micropowder is used as a raw material, and the weight parts are respectively: 60, 20, 20. Mix the powder for 2 hours until uniform, put it into a molybdenum cup 2 with an inner diameter of 14.8 mm, pre-press 2 g of the mixed powder 1 at 5 MPa, heat treat at 500°C for 0.5 hours in a vacuum, and put it into a heated graphite tube 3, and finally insulate the assembled parts Sheet 4, thermal insulation graphite sheet 5, conductive metal sheet 6, and conductive steel cap 7 are put into the pyrophyllite composite block 8 together. 7 The inner diameter is 16mm and the height is 17mm. The six-sided top press (CS- , 6×14000 KN) for high-temperature and high-pressure synthesis, the synthesis conditions are 5 GPa, 1400 ℃, the sintering holding time is 5 minutes, and then the temperature is slowly lowered to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com