Method and application of preparation of polynitrogen two-dimensional covalent organic framework materials using 1,3,5-triformylphloroglucinol as the center

A triformylphloroglucinol, covalent organic framework technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the practical application of two-dimensional covalent organic framework materials difficult gas separation membrane materials, gas Selective permeation, unsatisfactory separation effect, etc., to achieve the effect of improving gas separation performance, wide application and good synthesis repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 NO 2 - Preparation of TpPa

[0041] Add 31 mg of 1,3,5-triformylphloroglucinol (Tp) and 34.5 mg of o-nitro-p-phenylenediamine (NO 2 -Pa) powder. 1.5 ml of 1,4-dioxane and 1,3,5-trimethylbenzene were added as solvents respectively. Add 0.5 ml of 3 mol per liter of acetic acid as a catalyst. The mixture was homogenized after sonication for 10 min. Then put the Pyrex glass tube into the liquid nitrogen bath to freeze. After the liquid in the tube solidifies, turn on the vacuum oil pump to pump air, and then take the sample tube out of the liquid nitrogen bath and wait for the liquid to melt. This freezing-pumping- The melting cycle needs to be performed three times. The vacuum-tight sample tube was placed in an oil bath at 120°C and heated for 72 hours to obtain a dark red powder. The powder was washed with tetrahydrofuran, methanol and acetone, extracted and washed with ethanol and dichloromethane, and dried under vacuum at 120°C for 12 hours to obtain NO ...

Embodiment 2

[0043] Example 2 NH 2 - Preparation of TpPa

[0044] Get 150 mg of NO produced in Example 1 2 -TpPa, 3 g SnCl 2 2H 2 O was placed in a round-bottomed flask, 5 ml of anhydrous tetrahydrofuran was added, and refluxed at 77°C for 3 hours under the protection of nitrogen.

[0045] Use 70 milliliters of 3 moles per liter of hydrochloric acid to quench after the reaction is completed, and then wash with 70 milliliters of 1 moles per liter of hydrochloric acid, deionized water, methanol and acetone for 3 times, and obtain a brown powder after vacuum drying at 120 degrees Celsius for 12 hours. Nitrogen two-dimensional covalent organic framework material NH 2 -TpPa.

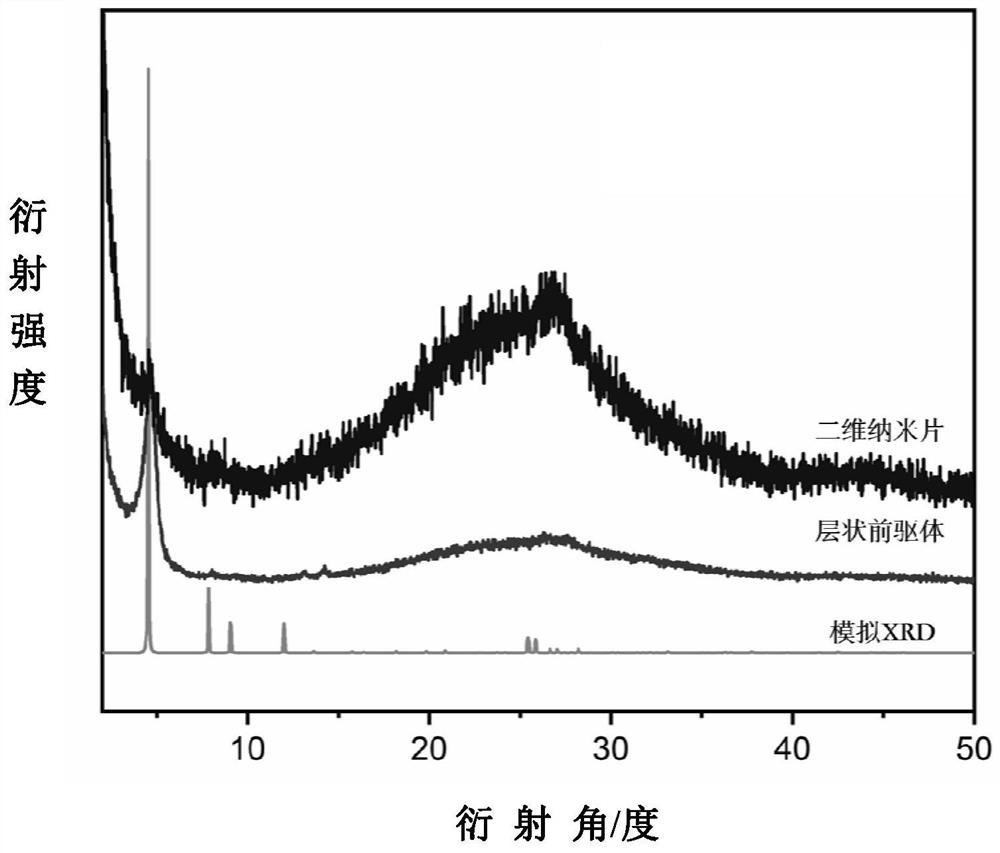

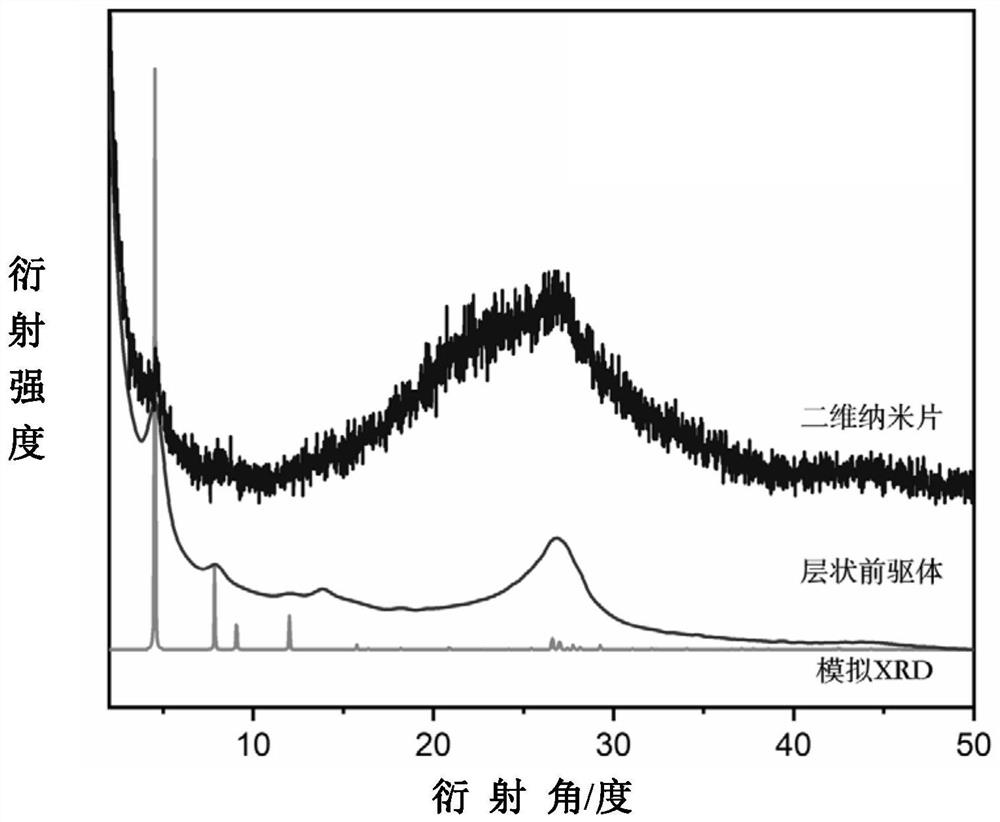

[0046] X-ray diffraction (such as image 3 ) to confirm the product and simulated structure (such as Figure 4 ) is consistent, has a layered structure, and its (100) characteristic peak appears near 5°. FTIR characterization showed that, compared to NO 2 -TpPa spectral curve, NH 2 -TpPa at 1336cm -1 The nitro ...

Embodiment 3

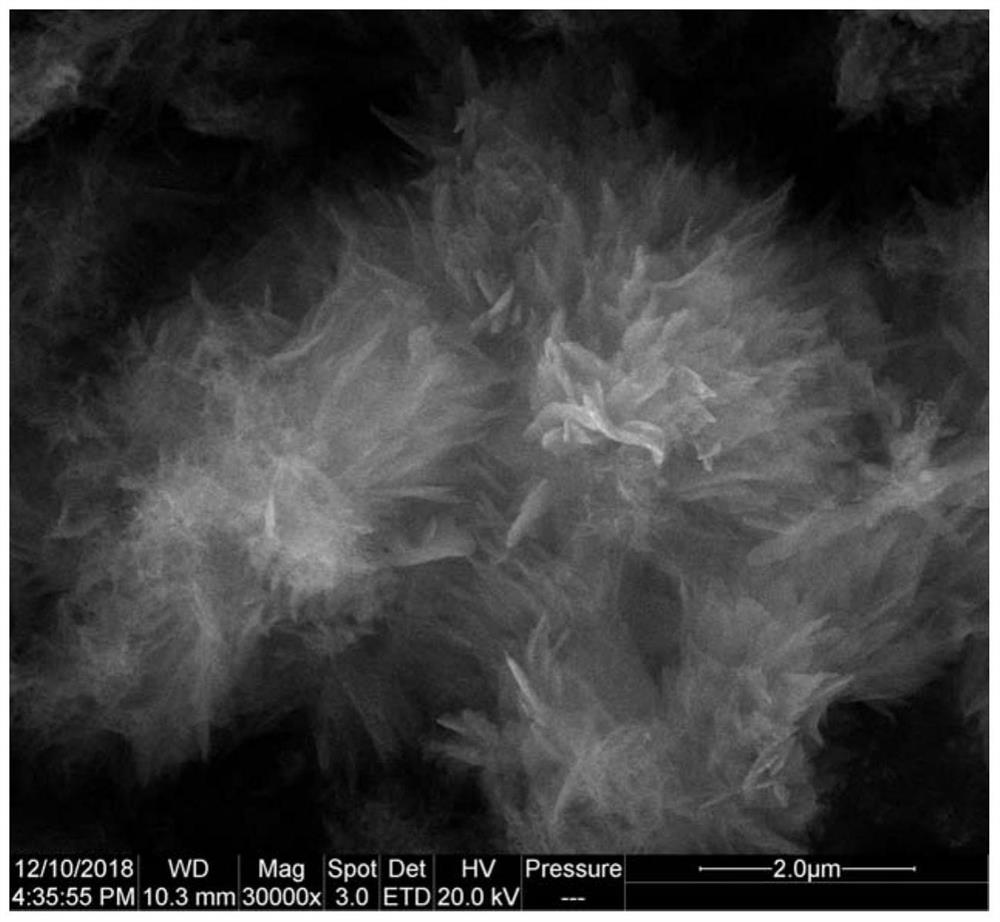

[0047] Example 3 NO 2 - Preparation of TpPa nanosheets

[0048] The NO prepared in Example 1 2 10 mg of TpPa powder was dispersed in 100 ml of n-butanol solution, sealed in a 500 ml ball mill jar, and ball milled at a speed of 60 rpm for 1 hour. Subsequently, the ethyl acetate dispersion of the nanosheets was taken out and allowed to stand for 15 days to remove unopened large particles. The dispersion liquid obtained after standing has obvious Tyndall phenomenon, even after standing for one month, Tyndall phenomenon is still clearly visible. The scanning electron microscope pictures show that the nanosheets and the precursors present a very different morphology, and the flower cluster precursors present flake nanosheets after peeling off (such as Figure 8 ). Transmission electron microscope pictures show that the average size of nanosheets is about 500-1000 nanometers, and they are very easy to fold (such as Figure 9 ). Atomic force microscope pictures show that the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com